110kV Transmission Tower: Complete Specifications, Pricing & Buyer's Guide

2025-12-20

A 110kV transmission tower is a steel lattice or monopole structure standing 20-40 meters tall, weighing 5-15 tons, built from Q345B steel (ASTM A572 Grade 50 equivalent) with hot-dip galvanizing per ASTM A123. These towers support high-voltage power lines across spans of 200-400 meters and last 50-80 years with proper maintenance.

Here's what you need to know before purchasing.

110kV Transmission Tower Specifications at a Glance

| Specification | Suspension Tower | Tension Tower | Terminal Tower | Angle Tower (30°) |

|---|---|---|---|---|

| Height Range | 20-35m | 25-40m | 28-45m | 25-40m |

| Weight | 5-8 tons | 8-15 tons | 12-20 tons | 10-18 tons |

| Base Width | 4-6m | 5-8m | 6-10m | 5-9m |

| Max Span | 400m | 350m | N/A | 300m |

| Line Deviation | 0-2° | 2-15° | Dead-end | 15-60° |

| Steel Grade | Q235B/Q345B | Q345B/Q420B | Q345B/Q420B | Q345B/Q420B |

We've manufactured over 300,000 tons of transmission towers since 2008, and one thing remains consistent: buyers who understand these specs upfront avoid costly project delays.

What Makes 110kV Different from Other Voltage Classes?

110kV sits in the "extra-high voltage" category—higher than 66kV distribution lines, but below 220kV bulk transmission. This matters for your project because:

Ground clearance requirements: 110kV lines need minimum 7 meters clearance over roads. Miss this, and you're redesigning your tower heights.

Insulator string length: Expect 1.2-1.5 meters for suspension strings. This affects your cross-arm dimensions.

Conductor spacing: Phase-to-phase spacing runs 3.5-4.5 meters horizontally. Tighter than 220kV, but still substantial.

If you're working on a 66kV transmission tower project, the height and weight requirements drop significantly—typically 15-25 meters and 3-8 tons.

Types of 110kV Towers: Which Do You Need?

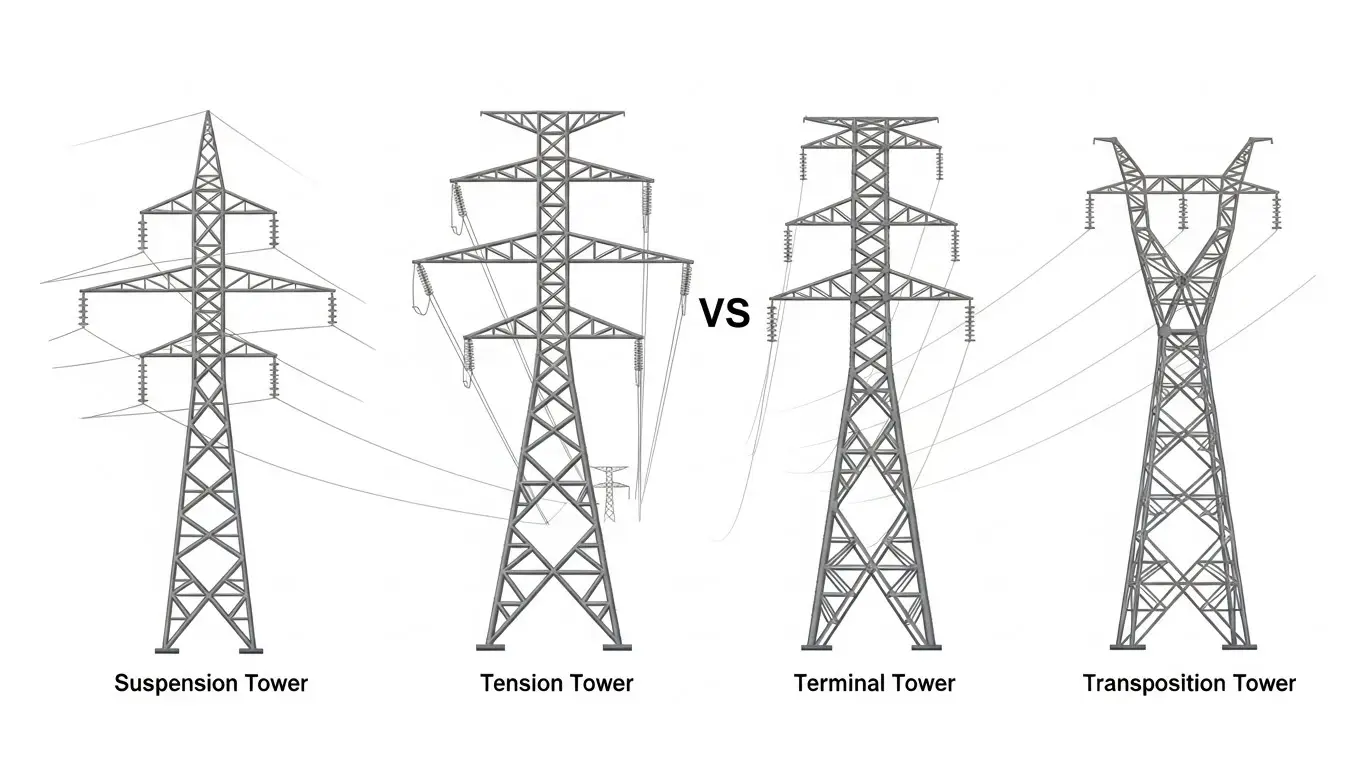

By Function

Suspension towers (Type A) handle straight runs with up to 2° deviation. They're your workhorse—accounting for 60-70% of most transmission lines. Lighter weight means lower costs.

Tension towers (Type B/C) resist conductor pull at angle points. Type B covers 2-15° angles; Type C handles 15-30°. Heavier steel, deeper foundations.

Terminal towers anchor line ends at substations. These dead-end structures carry full conductor tension—expect the heaviest weights in your project.

Transposition towers swap conductor positions every 50-100km to balance impedance. Specialized but critical for long lines.

By Design

Lattice steel towers dominate 110kV applications. The open framework distributes wind load efficiently—critical in typhoon-prone regions we supply across Southeast Asia.

Monopoles work better in urban areas where right-of-way is tight. Higher material cost per tower, but simpler foundations offset some expense.

Guyed towers suit flat terrain with good soil. Lower steel weight (guy wires share the load), but they need more ground space.

For high voltage tower projects above 220kV, lattice designs become nearly universal due to structural demands.

Material Standards: What to Specify in Your RFQ

Steel grade matters more than most buyers realize. Here's the standards cross-reference table our engineering team uses:

| Component | Chinese Standard | ASTM Equivalent | European (EN) |

|---|---|---|---|

| Tower legs | Q345B | A572 Grade 50 | S355JR |

| Bracing members | Q235B | A36 | S235JR |

| High-stress members | Q420B | A572 Grade 65 | S420 |

| Bolts | Grade 8.8 | A394 Type 0/1 | ISO 898 Class 8.8 |

| Galvanizing | GB/T 13912 | A123 | ISO 1461 |

| Welding | — | AWS D1.1 | EN 1090 |

Our facility runs ISO 9001:2015-certified production with CE marking (EN 1090) for European projects. That dual certification saves you audit headaches when exporting towers internationally.

Galvanizing thickness is non-negotiable: 86μm minimum average per ASTM A123. Thinner coatings fail in coastal environments within 15-20 years instead of the expected 30+.

110kV Tower Pricing: What to Expect

Tower costs break down by weight, and prices fluctuate with steel markets. Current ranges:

| Tower Type | Weight Range | Price/Ton (FOB) | Estimated Unit Cost |

|---|---|---|---|

| Light suspension | 5-6 tons | $950-1,100 | $4,750-6,600 |

| Standard suspension | 6-8 tons | $950-1,100 | $5,700-8,800 |

| Light tension | 8-12 tons | $1,000-1,200 | $8,000-14,400 |

| Heavy tension | 12-18 tons | $1,100-1,300 | $13,200-23,400 |

| Terminal | 15-25 tons | $1,200-1,500 | $18,000-37,500 |

Volume matters. Our minimum order is 20 tons, but pricing improves significantly above 100 tons. With 40,000 tons annual capacity across our 33,000m² facility, we can handle large-scale grid projects without lead time surprises.

Cost factors beyond steel:

- Foundation concrete and rebar (add 15-25% to tower cost)

- Hardware and insulators (8-12% additional)

- Shipping (varies dramatically by destination—land transport to Central Asia beats sea freight to Africa on speed but not cost)

- Installation labor (local rates dominate)

How to Select the Right 110kV Tower for Your Project

Your terrain and climate drive tower selection more than voltage class does.

For flat agricultural land: Standard lattice suspension towers with 350-400m spans minimize tower count and foundation costs.

For mountainous regions: Shorter spans (200-250m), heavier tension towers at frequent angle points. Helicopter erection may be required—design for it.

For coastal/high-corrosion zones: Specify 100μm+ galvanizing thickness. Consider weathering steel for critical members.

For high wind areas (typhoon zones, open plains): Cat-head or cup-type tower heads handle asymmetric wind loads better than flat cross-arms.

For ice-prone regions: Design for combined wind + ice loading. Tower weights increase 20-40% over standard designs.

Our engineering team has designed transmission towers for projects across 20+ countries—Nicaragua to Myanmar, Sudan to Poland. Terrain challenges don't surprise us anymore.

Installation and Foundation Requirements

Foundation costs catch many project managers off-guard. Budget appropriately:

Lattice tower foundations (four separate footings):

- Footing depth: 2-4 meters typical

- Concrete volume: 8-20 m³ per tower

- Rebar: 400-1,000 kg per tower

Monopole foundations (single drilled shaft):

- Shaft depth: 8-15 meters

- Shaft diameter: 1.5-2.5 meters

- Concrete volume: 30-60 m³ per tower

Foundation design depends heavily on soil conditions. Get geotechnical surveys done early—discovering poor soil after tower fabrication starts creates expensive delays.

Typical installation timeline:

- Foundation construction: 5-7 days per tower

- Tower assembly (ground): 1-2 days

- Tower erection: 1 day with crane

- Conductor stringing: Concurrent with tower erection

Supplier Qualification: What to Verify

Not all tower manufacturers meet international project standards. Here's our recommended verification checklist:

Certifications to require:

- ISO 9001 quality management

- ISO 14001 environmental management

- ISO 45001 occupational health/safety

- CE marking (for European projects)

- AWS welding certification

Factory audit points:

- CNC cutting and drilling equipment (manual processes create tolerance issues)

- In-house galvanizing (outsourced HDG adds quality control variables)

- Trial assembly capability (catches fit-up problems before shipping)

- Material traceability system (mill certificates for every heat)

We built our own 12,000m² hot-dip galvanizing plant in 2019 specifically to control coating quality. When you're supplying State Grid and Southern China Power Grid domestically, plus international utilities, quality control isn't optional.

Check our quality management system and certifications for documentation examples.

Lead Time and Logistics

Realistic project timelines:

| Phase | Duration |

|---|---|

| Engineering/approval | 2-4 weeks |

| Steel procurement | 1-2 weeks |

| Fabrication | 20-30 days |

| Galvanizing | 3-5 days |

| Packing/loading | 2-3 days |

| Sea freight (to Africa) | 35-45 days |

| Sea freight (to SE Asia) | 15-25 days |

| Rail (to Central Asia) | 15-20 days |

Packing standards matter for overseas projects. Profiles get bundled in drums under 2 tons, tied minimum 4 times for lengths under 5.8m. Every piece gets stamped with part numbers matching erection drawings—essential for field assembly in locations where our team isn't on-site.

Frequently Asked Questions

110kV transmission towers typically stand 20-40 meters tall (65-130 feet). Standard suspension towers average 25-30 meters, while tension and terminal towers reach 35-45 meters to accommodate additional clearance for angled conductors and dead-end strings.

A 110kV tower weighs between 5-25 tons depending on type. Suspension towers run 5-8 tons, tension towers 8-18 tons, and terminal towers 15-25 tons. Weight increases with angle deviation requirements and environmental loading conditions like wind and ice.

110kV transmission towers cost $950-1,500 per ton FOB China, translating to $5,000-37,500 per unit depending on type. Suspension towers ($5,000-9,000) cost less than tension towers ($8,000-24,000) or terminal towers ($18,000-37,500). Foundation and installation add 30-50% to delivered costs.

110kV towers use structural steel grades Q235B and Q345B (equivalent to ASTM A36 and A572 Grade 50). High-stress members may use Q420B. All steel receives hot-dip galvanizing per ASTM A123/ISO 1461 with minimum 86μm coating thickness for 30+ year corrosion protection.

A properly maintained 110kV transmission tower lasts 50-80 years. Hot-dip galvanized coatings provide 30+ years of corrosion protection. Tower lifespan depends on environmental conditions—coastal installations may require earlier maintenance than inland towers due to salt exposure.

The minimum ground clearance for 110kV lines is 7 meters over roads and 6 meters over non-traffic areas. Horizontal safety distances vary by jurisdiction but typically require 4-6 meters from buildings. Phase-to-phase conductor spacing is 3.5-4.5 meters.

Lattice towers use an open steel framework offering high strength-to-weight ratio, lower wind resistance, and easier maintenance access. Monopoles are single tubular columns with smaller footprint but higher material cost. Lattice dominates 110kV applications; monopoles suit space-constrained urban routes.

Select suspension towers for straight line sections (0-2° deviation), tension towers for angle points (2-60°), and terminal towers for line ends. Choose lattice designs for most terrain, monopoles for urban areas, and guyed towers for flat land with good soil. Environmental factors like wind, ice, and corrosion determine specific design parameters.

Get a Quote for Your 110kV Tower Project

We've supplied transmission towers to utility companies across 20+ countries since 2008. With 40,000 tons annual capacity, ISO/CE certification, and our own galvanizing facility, we deliver projects on specification and on schedule.

Contact our engineering team:

- Email: sales@xytowers.com

- WhatsApp: +86 15184348988

- Phone: +86-28-82688918

Or request a quote directly with your project specifications.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.