132kV Transmission Tower Price: Complete Cost Guide for 2026

2025-12-26

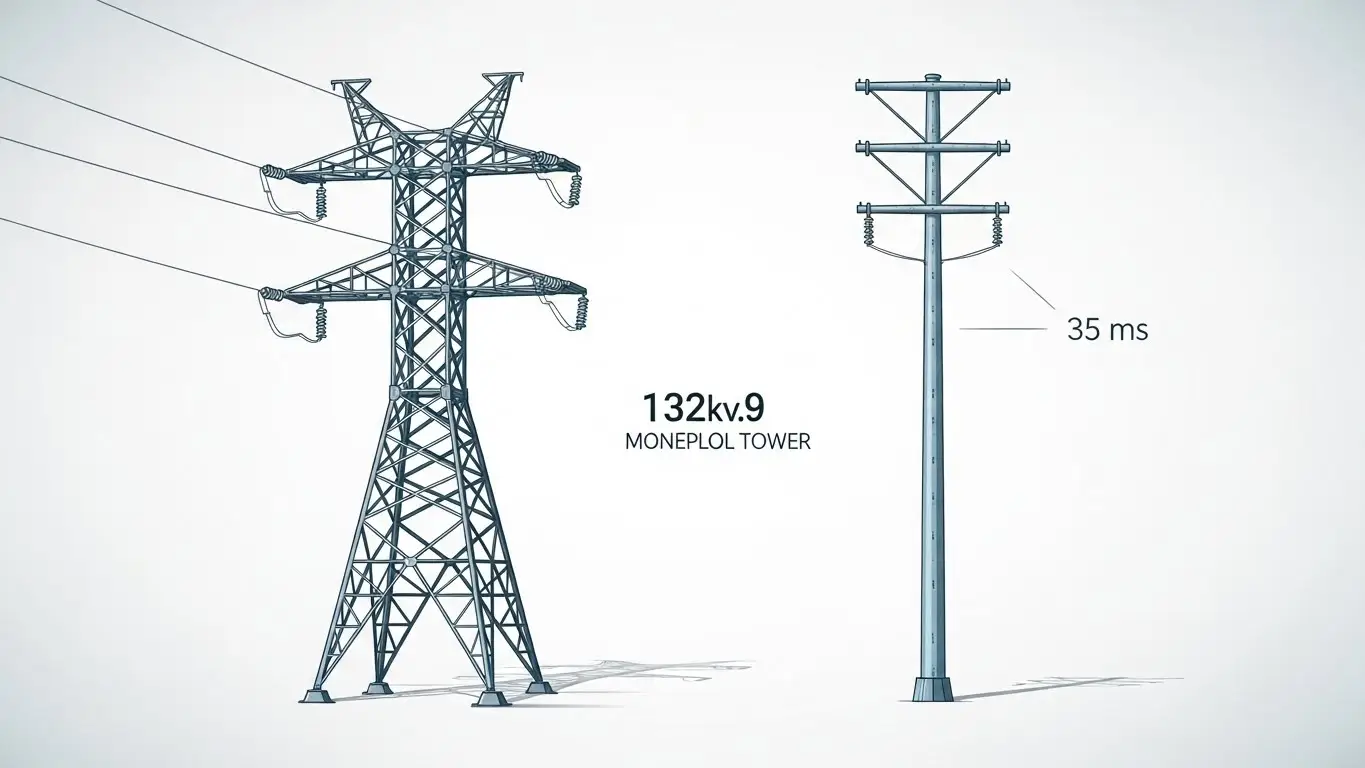

132kV transmission tower prices range from $980 to $1,600 per metric ton (FOB China) in 2025. Lattice steel towers sit at the lower end—$980-$1,200/ton—while monopole towers cost $1,200-$1,600/ton. A single 132kV tower typically weighs 3-8 tons, putting individual tower costs between $4,000 and $12,000 depending on height, circuit configuration, and galvanizing specifications.

Here's what you're actually paying for:

| Tower Type | Weight Per Unit | Price Per Ton (FOB China) | Cost Per Tower |

|---|---|---|---|

| Lattice (Single Circuit) | 3-5 tons | $980-$1,100 | $3,000-$5,500 |

| Lattice (Double Circuit) | 5-8 tons | $1,000-$1,200 | $5,000-$9,600 |

| Steel Monopole | 6-12 tons | $1,200-$1,600 | $7,200-$19,200 |

| Guyed Tower | 2-4 tons | $900-$1,100 | $1,800-$4,400 |

These prices assume standard specifications—Q345B steel, ASTM A123 hot-dip galvanizing (86μm average thickness), and AWS D1.1 welding standards. Custom requirements push costs higher.

What Actually Drives 132kV Tower Pricing

After 15+ years manufacturing transmission towers and completing thousands of projects across Nicaragua, Sudan, Myanmar, and Southeast Asia, we've seen every pricing variable imaginable. Here's what moves the needle:

Steel Grade and Raw Material Costs

The steel accounts for roughly 55% of your tower cost. Most 132kV towers use Q345B steel (equivalent to ASTM A572 GR50), which offers the right balance of strength and weldability. Drop to Q235B and you'll save 5-8%—but you'll need heavier sections to hit the same load capacity.

Raw steel prices fluctuate. Chinese domestic steel currently sits around $410/metric ton ex-works, while global export prices hover near $460/ton FOB. These base material costs ripple through finished tower pricing.

Galvanizing Specifications

Hot-dip galvanizing typically runs 18-22% of total tower cost. Per ISO 1461 and ASTM A123 standards, 132kV towers require minimum 80-100 microns of zinc coating for 30+ year corrosion protection. Our own galvanizing facility processes towers to an average 86μm thickness—exceeding minimum requirements while keeping costs competitive.

Thicker coatings cost more. Coastal or high-pollution installations often specify 100-120μm, adding 8-12% to galvanizing costs.

Tower Height and Design Complexity

Standard 132kV transmission towers range from 20-50 meters tall. Taller towers require heavier base sections, more steel per meter, and stronger foundations.

Tower function also matters:

- Suspension towers (straight-line sections): Lightest, cheapest

- Tension towers: 15-25% heavier than suspension

- Angle towers (direction changes): 20-35% premium

- Terminal towers (line endpoints): Heaviest, most expensive

A 30-meter double-circuit tension tower weighs roughly 6.5 tons. The same design at 45 meters? Expect 9-10 tons.

Order Volume

Minimum orders typically start at 10-20 tons—roughly 3-5 towers. Bulk orders (100+ tons) unlock 8-15% discounts. With our 30,000-ton annual production capacity, we handle orders from single prototype towers to full transmission line projects.

Lattice vs. Monopole: Which Costs Less for 132kV Lines?

This question comes up in nearly every project discussion. The short answer: lattice towers cost 20-40% less than monopoles of equivalent capacity. But "cheaper" isn't always "better."

| Factor | Lattice Tower | Steel Monopole |

|---|---|---|

| Price Per Ton | $980-$1,200 | $1,200-$1,600 |

| Fabrication Complexity | Low (angle steel sections) | High (plate bending, welding) |

| Installation Time | 3-5 days | 1-2 days |

| Foundation Cost | Lower (spread footings) | Higher (deep mono-foundation) |

| Visual Impact | Higher | Lower |

| Footprint | Larger (4 legs) | Smaller (single base) |

| Right-of-Way Required | More | Less |

Choose lattice towers when:

- Budget is the primary constraint

- You have ample right-of-way

- Rural or industrial areas where aesthetics don't matter

- Longer spans require heavier load capacity

Choose monopoles when:

- Urban or suburban locations demand minimal visual impact

- Limited right-of-way forces compact designs

- Faster installation timeline is critical

- Local regulations restrict lattice structures

For most 66kV and 110kV transmission lines, the economics favor lattice construction. At 132kV, the decision often hinges more on site constraints than pure cost.

132kV Transmission Line Cost Per Kilometer

Individual tower pricing only tells part of the story. Project managers need complete line costs. Here's what a typical 132kV double-circuit overhead line runs per kilometer:

| Component | Cost Range (USD) | % of Total |

|---|---|---|

| Steel Towers (3-4 per km) | $15,000-$28,000 | 32-38% |

| ACSR Conductors | $8,000-$12,000 | 17-22% |

| Concrete Foundations | $6,000-$12,000 | 13-18% |

| Insulators & Hardware | $4,000-$7,000 | 8-12% |

| Installation Labor | $10,000-$18,000 | 18-25% |

| Total Per Kilometer | $45,000-$75,000 | 100% |

Terrain drives massive variation. Flat agricultural land? Budget toward the lower end. Mountainous terrain with limited access? Double it.

Tower spacing depends on conductor sag calculations and terrain. Standard spans run 300-400 meters, meaning 3-4 towers per kilometer. Crossing towers (rivers, highways, railways) require taller structures with longer spans—and higher costs.

Technical Specifications That Affect Your Quote

When requesting quotes, manufacturers need specific parameters. Vague requests get vague pricing. Here's what to provide:

Essential Specifications:

- Voltage level: 132kV (obviously)

- Circuit configuration: Single or double circuit

- Tower types needed: Suspension, tension, angle, terminal (with quantities)

- Height range: Based on your terrain survey and clearance calculations

- Wind speed: Design wind speed per your local codes (typically 25-55 m/s)

- Span requirements: Maximum and typical spans

- Conductor specs: Type, size, weight per meter

- Ice loading: If applicable to your climate

Standards to Reference:

For international projects, specify which standards apply:

- Steel: Q345B (China), ASTM A572 GR50 (US), S355JR (EU)

- Galvanizing: ASTM A123, ISO 1461, or GB/T 13912

- Welding: AWS D1.1 or equivalent

- Design codes: IS 802 (India), ASCE/SEI (US), IEC 60826

Our engineering team uses PLS-Tower, AutoCAD, and BOCAD for design verification. We can work with your specifications or develop designs from your route survey data.

How to Get Accurate Quotes (Without the Runaround)

After fielding thousands of quote requests, we know what separates quick, accurate pricing from endless back-and-forth. Here's what gets you real numbers fast:

Include in Your RFQ:

- Project location and delivery port

- Total tonnage estimate (or tower quantities by type)

- Required certifications (ISO, CE, specific country standards)

- Timeline requirements

- Payment terms preference (T/T, L/C)

- Whether you need design services or have final drawings

Expect These Lead Times:

- Standard designs: 45-60 days from order confirmation

- Custom designs requiring engineering: 60-90 days

- Large projects (500+ tons): 90-120 days

Payment Terms:

Industry standard runs 30% deposit, 60% before shipment, 10% against documents. Letters of credit work for larger orders.

Quality Verification: What to Check Before Ordering

Low prices mean nothing if towers fail inspection. Here's how to verify manufacturer quality:

Certifications to Confirm:

- ISO 9001:2015 quality management

- GB/T 2694-2018 compliance (Chinese standard for transmission tower manufacturing)

- ASTM A123 galvanizing certification

- AWS D1.1 welding qualification

Factory Audit Checklist:

- CNC angle steel processing line

- Dedicated galvanizing facility (in-house preferred)

- Assembly test capability

- Material traceability system

- Third-party inspection acceptance

We welcome factory visits—customers regularly inspect production at our Chengdu facility. Third-party inspections (SGS, BV, TÜV) are standard for export orders. Every tower piece gets coded and tracked from raw material through shipment.

Frequently Asked Questions

How much does a 132kV transmission tower weigh?

A 132kV lattice tower weighs 3-8 metric tons depending on height and circuit configuration. Double-circuit tension towers run heavier—typically 6-8 tons. Steel monopole towers for the same voltage range from 6-12 tons due to their solid construction.

What is the height of a standard 132kV tower?

Standard 132kV towers range from 20 to 50 meters. Suspension towers in flat terrain might be 25-30 meters. River crossings, highway crossings, or hilly terrain require taller structures—sometimes exceeding 60 meters for special crossings.

How many 132kV towers are needed per kilometer?

Typically 3-4 towers per kilometer, based on 250-400 meter spans. Actual spacing depends on conductor weight, terrain, and wind loading. Mountainous routes might need 5-6 towers per kilometer with shorter spans.

How long do galvanized steel towers last?

Properly galvanized towers (80-100μm zinc coating per ASTM A123) last 30-50 years with minimal maintenance. Our high voltage transmission towers carry a 30-year warranty period. Coastal installations may require additional protective coatings.

Can you manufacture custom tower designs?

Yes. Our engineering team handles custom designs using PLS-Tower and SAP2000 software. Provide your line parameters (voltage, conductor, wind zone, terrain), and we develop optimized tower families. We've completed custom designs for projects across Africa, Southeast Asia, and South America since 2008.

Summary

132kV transmission tower pricing comes down to steel costs, galvanizing quality, tower complexity, and order volume. Budget $980-$1,200/ton for lattice towers, $1,200-$1,600/ton for monopoles. A complete 132kV line runs $45,000-$75,000 per kilometer including towers, conductors, foundations, and installation.

For accurate project pricing, contact our team with your specifications. We provide complete quotations within 48 hours for standard designs.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.