Anti-Corrosion Substation Supports for Desert Environments: Guide

2025-07-19

Introduction

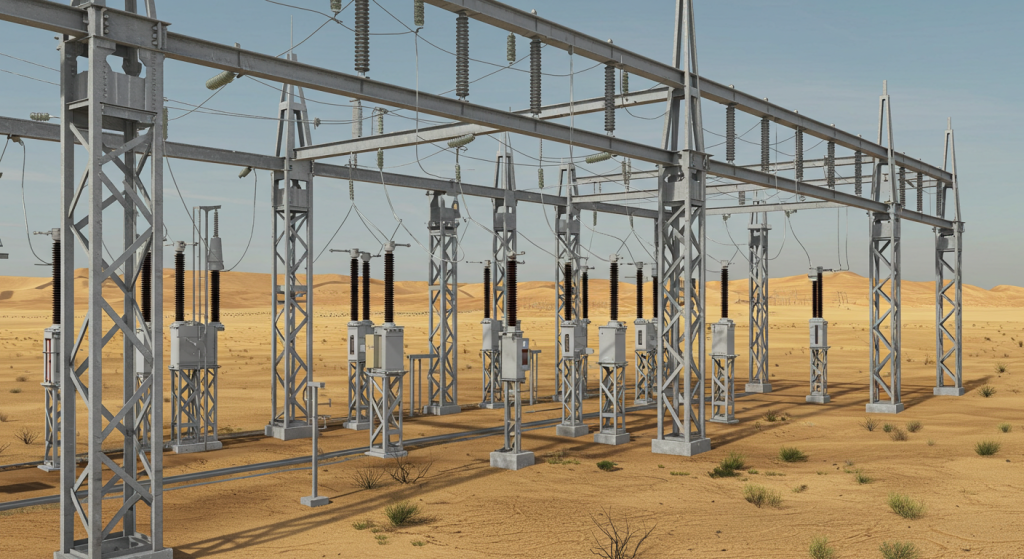

Desert and solar power substations face a myriad of challenges from extreme heat, solar radiation, strong winds, and sand. Corrosion is a large challenge, giving the need for substations to be specially designed and constructed to ensure sustainable operation while providing safe and corrosion-free operation during harsh environmental conditions.

XY Tower is focused on the design, construction, and installation of support systems specifically for regions with high temperatures and low moisture. The framework supports of our systems are constructed with steel that is hot-dip galvanized and undergoes advanced protective treatment. This approach improves maintenance economy, which, through consistency and reliability, strengthens grid dependability.

Why Desert Environments Demand Specialized Substation Supports?

When looking to power the substation supported on steel structures, the combination of heat, wind, and sand makes it a lot more challenging.

- Solar Radiation

Ultraviolet radiation leads to paint peeling, as well as surface cracking and overall deterioration from structural failure through fatigue.

- Temperatures Shift

A rapid drop in temperature from the daytime increase can result in sharp shifts, and combined with little outside air movement, leads to an overall different environment from what the air is used to. Such abrupt changes lead to the rapid expansion and contraction of steel, which adversely affects unequaled welds and durable joints over time.

- Sandbox Storms

These phenomena accelerate tarnishing through erosive surface marking.

Low Humidity Heightened by Damaging Particulate Matter

The infusion of minerals and ores, along with the parched atmosphere, strengthens creeping corrosion. This profoundly compromises the durability of ubiquitous steel constructions. Therefore, supports that are resistant to corrosion are needed for substations and other structures placed in desert areas. These supports incorporate hot dip galvanization, paints resistant to ultraviolet radiation, and structural-thermal shielding, which is designed to protect elements from the extreme heat characteristic of deserts.

We, at XY Tower, ensure each anti-corrosion substation supports for desert environments undergoes fitting that enables unfaltering performance under reliably extreme temperatures.

Key Features of Anti-Corrosion Substation Supports

1. Hot-dipped galvanization: Providing zinc covering, ensuring protection for thirty to fifty years.

2. Powder coating and anti-rust finishes: Protection against moisture, ultraviolet rays, and extreme temperatures.

3. High-temperature resistant steel: Preserves its structure and the integrity above 50 degrees super.

4. Sandstorm resistant design: Enclosed joints and smooth surface erosion resistant.

5. Framework stabilized against ultraviolet radiation: Protection from sunlight degradation.

They comply with the IEC requirements for anti-corrosion measures and ASTM A123 concerning the metallurgical grading of compounds as well as the galvanized coating thickness and quality.

Desert Substation Solutions

Perhaps XY Tower's most challenging project to date is the construction of power infrastructure in the desert regions because of their extreme solar radiation and ceaseless sandstorms. Our focus is the unrivaled anti-corrosion supports to substations, which are crafted from materials designed to withstand the harshest of deserts. We guarantee reinforced frameworks made with hot-dip galvanized steel coupled with protective UV coatings, which ensure absolute resistance to:

- Thermal expansion

- Subsidence suffocates starve degrees Celsius of open air.

- Dry air erosion and hot air erosion

- Relentless solar power switchyards and 220kV lines in remote desert areas

We Offer

- Modular and prefabricated steel designs

- ISO and IEC compliant engineering

- Custom design for wind loads and seismic zones

- Maintenance and rust-proof

These structures are crucial for Middle and South Asian countries, considering the extreme wear and tear. For complete assurance of powering your upcoming desert project, work begins with the XY Tower product page.

Galvanization Workflow at XY Tower

To achieve the desired quality and ensure the protective characteristics remain effective over time, we carry out the entire galvanization process within the company. Our five-step procedure includes:

1. Surface Preparation: Degreasing, Pickling, and Rinsing

2. Fluxing: Pre-Treatment of Zinc Ammonium Chloride

3. Hot Dip Galvanizing: Immersion in Molten Zinc at 450°C

4. Cooling and Inspection: Thermal Equilibration and Visual Inspection

5. Coating Thickness Verification per ISO 1461 and ASTM A123 standards

Custom Engineering for Desert Climates

In addition to the unique shifting sand loads, each anti-corrosion substation supports for desert environments encounters an additional challenge of extreme seasonal heat and cold. This is an engineering challenge. We offer customized substation support solutions designed for these harsh environments. We offer the following:

- Lightweight modular lattice frameworks that are easy to transport and assemble.

- Prefabricated steel substation frames for rapid deployment.

- Calculation of wind and seismic loading for structural integrity.

- Evaluation of anti-corrosion protection against salt spray exposure over time.

- Strain analysis for thermal cyclic differential movement.

In nature, our anti-corrosion supports in the UV scrubbed bolted grid mounted substations support the concept of sustainability. We create optimally bolted substations for weather conditions, site-specific soil properties, structural loads, geotechnical demands, and more to allow for maintenance-free operation even in extreme climates.

Benefits From the Use of Anti-Corrosion Substation Structures in Desert Areas

- Reliability Over Time

Provides low-maintenance and remains structurally sound for more than three decades.

- Protection from Corrosive Environmental Factors

Safeguarded against sandstorms, extreme UV radiation, and elevated temperatures.

- Reduced Environmental and Operational Costs

Cost-effective due to lower deficiency replacement costs, no repainting required, and low upkeep.

- Compliance and Quality Certificate

Complies with global safety and structural design benchmarks, regulatory requirements, and compliance.

- Accelerated Installation Process

Modular/pre-fab components lead to faster completion times for the project.

Reliability Control at XY Tower

Quality for business at XY Tower is an attribute, but for these bolted structures, it is a necessity. Every supporting structure of a substation calls for meticulous design engineering so it can endure the heat of the desert. Therefore, we designed a contracted quality control system based on international benchmarks and best engineering techniques for the needed trustworthiness. No errors will occur when every step is followed in:

- Global compliance, third party ISO certified anti-corrosion structures

- Coating, welding, and adhesion, ultrasonic and x-ray testing

- Wind, heat, and seismic stressor simulations using FEA

- Environmental testing, such as salt spray and accelerated UV aging

- Steel certification encompasses the raw material to the installation of the finished product.

For all units, QA/QC precision oversight is performed and signed off for each section of the fabrication sequence. Each process begins with galvanization and concludes with the final bolt tightened, and is stringently regulated to guarantee the anti-corrosion substation supports will sustain the harshest climates for decades.

Conclusion

The broad ecological and climatological characteristics of the desert help define its structural subdivisions. Anti-corrosion substation supports for desert environments cover substation supports while offering reliability and protection; the covers comprise conventional steel’s strength. Desert-grade structures now enable power delivery to Sahara solar farms and oil installations in the Middle East. XY Tower not only leads in the fabrication of iron and steel frameworks, but also endures extreme temperature variations and harsh geographically influenced conditions.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.