Camouflage Telecom Tower: Tree & Palm Designs

2025-12-25

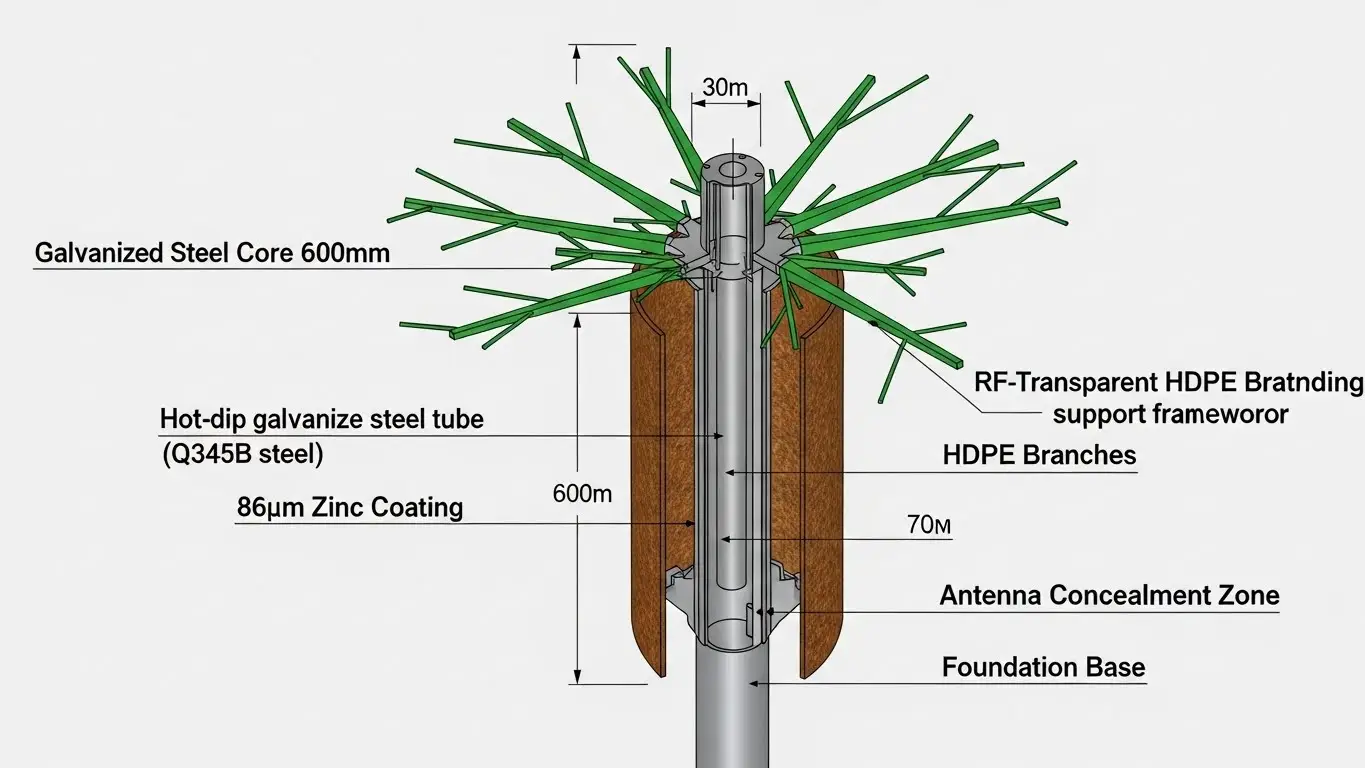

A camouflage telecom tower is a cellular antenna structure disguised as a natural tree to meet aesthetic regulations in residential and scenic areas. Built on galvanized steel monopole cores ranging from 15 to 50 meters in height, these towers feature RF-transparent plastic branches and UV-resistant bark coatings. Common designs include monopine (pine tree) and monopalm (palm tree) configurations, which add $100,000-$150,000 to construction costs but reduce permit approval time by 40-60% through improved community acceptance and compliance with municipal camouflage requirements.

The decision to use a camouflaged design isn't just about aesthetics. It's about securing permits faster and avoiding years of community opposition that can delay or kill your project entirely.

What Is a Camouflage Telecom Tower?

Think of it as a standard monopole tower wearing a disguise. The core structure remains identical—a hot-dip galvanized steel tube that provides the structural integrity. What changes is the exterior treatment.

The "camouflage" comes from two key elements: synthetic bark wrapping the steel pole and RF-transparent branches that conceal antennas and equipment. Unlike decorative additions, every component must be engineered to withstand wind loads while allowing radio signals to pass through unimpeded.

Our engineering team at X.Y. Tower designs these structures using ANSI/TIA-222-G-2 standard software, ensuring they meet the same structural requirements as conventional towers. The difference shows up in your permit hearings, not your network performance.

The concept emerged in 1992 when Larson Camouflage in Denver, Colorado created the first "monopine" tower. That invention turned into an industry standard after the Telecommunications Act of 1996 restricted local governments from blocking tower construction outright. Many municipalities responded by requiring camouflaged designs instead.

Types of Camouflage Telecom Towers

Your environment dictates your design. Choose wrong, and your "tree" stands out worse than a bare steel pole.

Monopine (Pine Tree) Towers

Best for forested areas, northern climates, and mountainous regions where evergreen trees dominate the landscape.

Height range spans 15 to 50 meters, with branches positioned to completely conceal antenna arrays. The evergreen design solves the seasonal problem—no awkward bare "tree" standing next to deciduous neighbors that shed their leaves.

Branch density determines both cost and effectiveness. Sparse branches save money but fool nobody. Full coverage costs more but actually blends in. Our production team at X.Y. Tower's 40,000-ton annual capacity facility manufactures branch assemblies that survive winds exceeding 80 mph through proper reinforcement of the steel core.

Monopalm (Palm Tree) Towers

Designed specifically for coastal areas, beach resorts, tropical and subtropical zones where palm trees occur naturally.

Height typically ranges from 20 to 45 meters. The frond design differs fundamentally from pine branches—long, flexible elements that move naturally in wind rather than rigid evergreen branches.

Advanced designs include "dead frond skirts" at the tower base, mimicking the natural accumulation of dried fronds on real palms. This detail dramatically improves the disguise in environments where every resident knows how real palms behave.

Broadleaf and Deciduous Tree Towers

These work in urban parks and suburban residential areas where elm, eucalyptus, or oak trees dominate.

The challenge: seasonal change exposes the disguise when surrounding trees lose leaves. Smart placement near actual evergreen trees or in mixed forests helps mitigate this limitation.

Specialty Camouflage Designs

Saguaro cactus towers serve desert regions. Clock towers and water tower concealment work in industrial areas. Flagpole designs suit civic buildings and commercial developments.

Each requires custom engineering. The principles remain constant—structural integrity per TIA-222 standards wrapped in contextually appropriate camouflage.

Technical Specifications Comparison

Real decisions require real data. Here's what different designs actually deliver:

| Specification | Monopine | Monopalm | Broadleaf | Specialty |

|---|---|---|---|---|

| Height Range | 15-50m | 20-45m | 15-40m | 10-35m |

| Base Diameter | 400-800mm | 450-750mm | 400-700mm | 300-900mm |

| Wind Resistance | 80+ mph | 85+ mph | 75+ mph | Varies |

| Weight Load | Heavy | Medium-Heavy | Medium | Varies |

| Branch Material | HDPE/FRP | HDPE/FRP | HDPE/FRP | Custom |

| Bark Material | UV-resistant coating | Textured coating | Molded coating | Context-dependent |

| RF Transparency | 95-99% | 95-99% | 95-99% | 90-99% |

| Service Life | 20-30 years | 20-30 years | 20-25 years | 20-30 years |

| Maintenance Interval | 5-7 years | 5-7 years | 4-6 years | Varies |

| Best Climate | Temperate/Cold | Tropical/Coastal | Temperate | Specific |

Materials and Construction Standards

Your tower's 30-year lifespan depends entirely on material quality. Cheap materials fail fast.

Steel Core Construction

We manufacture the core structure from Q235B, Q345B, or Q420B steel grades depending on height and load requirements. Each segment gets hot-dip galvanized at our dedicated HDG factory in Guanghan, where we control the zinc coating thickness to exceed standard specifications.

The galvanizing process isn't optional. It's the difference between a tower that lasts 30+ years and one that shows rust damage within five years. Our ISO 9001 certified process ensures consistent coating thickness of 86 micrometers minimum, meeting ASTM A123 standards.

Segmented shaft design allows transportation and site assembly. Heights up to 50 meters require 4-6 segments, each precisely machined for slip-fit or bolted connections.

Bark and Texture Elements

The bark isn't paint. It's molded material created from actual tree bark patterns, then finished with UV-resistant coatings rated for 20-30 years without fading.

Our manufacturing process starts with mold creation from real bark samples. This captures the natural cracks, curves, and texture details that make or break the illusion. Artisans then apply multi-layer coating systems with appropriate color variations—real bark isn't uniform.

The coating adheres to the already-galvanized steel, providing two layers of protection. Maintenance involves simple repainting every 10-15 years if fading occurs in harsh climates.

Branch and Foliage Materials

High-Density Polyethylene (HDPE) dominates branch construction. The material must be:

- RF-transparent (letting signals pass through)

- UV-resistant (surviving decades of sun exposure)

- Flexible enough to move naturally in wind

- Strong enough to survive storms without detachment

Each branch element gets engineered for specific wind load scenarios. More branches mean more weight, requiring reinforced trunk structures. This cascading effect drives up costs quickly—why skimping on branches often backfires.

The material science matters. Low-grade plastics become brittle within 5-10 years, leading to branch failure and litter problems. Quality HDPE maintains flexibility and strength for the tower's full service life.

Compliance Standards You Must Meet

Every camouflage tower we design at X.Y. Tower must satisfy the same structural requirements as conventional towers, plus additional aesthetic regulations.

TIA-222-H (Latest: Rev I as of 2024) This structural standard defines minimum load requirements for antenna-supporting structures. Key provisions include:

- Wind loading calculations based on exposure category

- Seismic loading considerations for earthquake zones

- Foundation specifications matching soil conditions

- Structural analysis methods for existing structure modifications

The standard applies regardless of camouflage. Your pine tree must survive the same 3-second gust wind speeds as a lattice tower.

ISO 9001 Quality Management Manufacturing quality directly impacts tower reliability. Our ISO 9001 certification covers the entire production process—from steel procurement through final assembly inspection. This isn't paperwork; it's documented proof that we follow consistent procedures that produce consistent results.

ASCE 7-22 Loading Criteria Recent updates aligned TIA-222 with ASCE 7-22 standards, particularly for wind speed calculations. The shift to ultimate gust wind speeds changed how we calculate design loads, generally resulting in more conservative (stronger) structures.

Local Zoning Ordinances These vary dramatically. Some municipalities require camouflage in all residential zones. Others specify minimum distances from residences where camouflage becomes mandatory. Many historic districts allow towers only if completely concealed.

Your project timeline depends on understanding these requirements before design starts, not after.

Cost Analysis: Investment vs. Permit Speed

The numbers tell a clear story about when camouflage makes financial sense.

Base Cost Components

Standard monopole tower (30m height):

- Steel monopole structure: $45,000-$60,000

- Foundation: $15,000-$25,000

- Installation: $10,000-$15,000

- Total: $70,000-$100,000

Same tower with camouflage:

- Base monopole: $45,000-$60,000

- Camouflage branches (per meter): $2,500-$3,500

- Bark coating system: $15,000-$25,000

- Structural reinforcement: $12,000-$18,000

- Additional installation complexity: $8,000-$12,000

- Total: $170,000-$250,000

The premium ranges from $100,000 to $150,000 depending on design complexity and branch density.

Return on Investment

The ROI calculation isn't just about construction costs. It's about time:

Permit approval timeline:

- Standard tower in residential area: 12-24 months (if approved at all)

- Camouflage tower same location: 6-12 months

- Time savings: 40-60%

Community opposition costs money too. Attorney fees for permit appeals, public hearings, alternative site studies—these expenses add up quickly. One delayed project can cost more than three camouflaged towers.

Lease rate advantages: Premium locations (beach resorts, upscale residential, tourist areas) justify higher lease rates when visual impact gets minimized. The $100K camouflage investment enables tower placement in locations that would otherwise reject any tower at all.

| Cost Factor | Standard 30m | Camouflage 30m | Difference |

|---|---|---|---|

| Base Structure | $45K-$60K | $45K-$60K | $0 |

| Camouflage Add-on | $0 | $75K-$110K | +$75K-$110K |

| Foundation | $15K-$25K | $18K-$30K | +$3K-$5K |

| Installation | $10K-$15K | $18K-$25K | +$8K-$10K |

| Total Capex | $70K-$100K | $170K-$250K | +$100K-$150K |

| Permit Timeline | 12-24 months | 6-12 months | -50% time |

| Annual Maintenance | $2K-$4K | $3K-$6K | +$1K-$2K |

| 20-Year TCO | $110K-$180K | $230K-$370K | +$120K-$190K |

Applications: Where Camouflage Makes Sense

Not every location needs or justifies the camouflage premium. Here's where it matters:

Urban and Residential Areas

Municipal codes often mandate camouflage within 500 feet of residential properties. Historical precedent: communities learned they can't block towers but they can require aesthetic treatments.

Our experience with projects across Southeast Asia and Africa shows similar patterns emerging. As telecom infrastructure expands, aesthetic requirements follow economic development.

National Parks and Protected Areas

Environmental regulations frequently require camouflage to minimize visual impact on scenic vistas. Park services prioritize maintaining natural aesthetics while acknowledging connectivity needs.

Design selection matters enormously. A palm tree in an alpine forest fails worse than a bare monopole. Match the dominant local species. Our design team at X.Y. Tower reviews site photos before recommending specific configurations.

Beach Resorts and Golf Courses

Premium recreational properties demand premium aesthetics. The return on camouflage investment shows up directly in property values and customer satisfaction.

Monopalm designs dominate these applications. The natural presence of palms in resort landscaping makes integration seamless when executed properly.

Historical Districts

Preservation boards exercise strict control over new construction. Telecommunications infrastructure becomes acceptable only when concealed effectively.

Success requires early engagement with preservation authorities. Submit multiple design options showing how camouflage respects historical character while meeting technical requirements.

Advantages of Camouflaged Designs

The benefits extend beyond just getting permits approved.

Accelerated Permitting Data from our international projects shows 40-60% reduction in approval timelines when camouflage gets specified from project start. Municipalities appreciate applicants who proactively address aesthetic concerns rather than fighting over bare steel poles.

Community Acceptance Public opposition collapses when visual impact gets minimized. Our 25-meter monopalm project in a Southeast Asian beach resort faced zero community resistance because it blended seamlessly with existing palm landscaping.

Property Value Protection Adjacent property owners often oppose towers due to perceived property value impact. Effective camouflage eliminates this concern, removing a major source of project opposition.

Same Structural Performance Camouflage doesn't compromise functionality. The tower meets identical wind load, seismic, and antenna capacity specifications as conventional designs. Our engineering team ensures this through proper reinforcement of the steel core to handle additional weight.

Regulatory Compliance In jurisdictions requiring camouflage, it's not optional. The question becomes whether you invest appropriately to create effective camouflage or waste money on poor execution that satisfies regulations while fooling nobody.

Limitations and Honest Considerations

Every solution has tradeoffs. Here's what you need to know before committing:

Significant Cost Premium The $100,000-$150,000 additional cost represents 100-150% increase over standard monopole construction. Projects with tight budgets struggle to justify this unless permitting requirements make it mandatory.

Small operators and rural deployments often can't absorb this premium. The economics work best for carriers with multiple sites amortizing design costs across projects.

Maintenance Complexity Branch replacement becomes necessary as weather, UV exposure, and age degrade materials. Budget $5,000-$15,000 every 10-15 years for refurbishment.

Access challenges increase maintenance costs. Climbing around branches adds time and safety considerations compared to bare steel structures.

Environmental Impact of Materials Plastic branches eventually degrade. Small plastic pieces from aging branches can litter the ground below, potentially entering local ecosystems. Quality materials minimize this problem but don't eliminate it entirely.

Responsible operators factor decommissioning costs into total project budgets. Complete branch removal and disposal adds expense at end-of-life.

Height and Weight Limitations Physics imposes real constraints. Taller towers require exponentially more structural reinforcement to support branch weight. Beyond 50 meters, the engineering complexity and cost often make camouflage impractical.

Seasonal Mismatch Risk Deciduous tree designs create obvious problems when real trees lose leaves while your "tree" remains fully foliated. Evergreen designs (pine, palm) avoid this issue, explaining their market dominance.

The Uncanny Valley Problem Poor execution creates structures more noticeable than bare monopoles. Half-hearted branch coverage, wrong species selection for the location, or cheap materials that fade quickly—all sabotage the entire investment.

Quality execution requires quality materials and proper design. Our recommendation: do it right or don't do it at all.

Design Selection Framework

Choosing the right camouflage design requires systematic evaluation of multiple factors.

Step 1: Regulatory Assessment Start by understanding what's required vs. what's optional. Some jurisdictions mandate specific design standards. Others leave discretion to the applicant.

Request pre-application meetings with planning departments. Ask explicitly: What camouflage requirements apply to this location? What designs have they approved previously?

Step 2: Environmental Context Survey the actual site and surrounding area. What trees naturally occur here? What heights? What density?

Photography helps. Take reference photos from multiple angles showing the site context. Share these with your engineering team for design recommendations.

Step 3: Height Requirements Network coverage drives tower height. Determine minimum height needed for adequate coverage before worrying about camouflage options.

If coverage requires 50+ meters and local trees max out at 25 meters, rethink the site entirely. Towering above surrounding trees defeats camouflage purposes.

Step 4: Wind and Environmental Loading Coastal locations face higher wind loads. Seismic zones need additional structural considerations. Ice loading matters in northern climates.

We design using TIA-222 standards that account for these factors. Still, environmental extremes increase costs as structural reinforcement requirements escalate.

Step 5: Budget Reality Check Calculate total project costs including camouflage premium. Compare against permit probability and timeline without camouflage.

Sometimes the math works clearly. Other times alternative sites make more sense than expensive camouflage at a problematic location.

Step 6: Long-Term Maintenance Planning Budget the 20-30 year total cost of ownership, not just construction. Include refurbishment cycles in your financial analysis.

Operators with in-house maintenance teams handle this more efficiently than those contracting all work externally.

| Environment | Recommended Design | Typical Height | Key Considerations | Budget Range |

|---|---|---|---|---|

| Dense Forest | Monopine | 20-40m | Match local pine species | $150K-$220K |

| Coastal Resort | Monopalm | 25-35m | Wind resistance critical | $160K-$240K |

| Urban Residential | Monopine/Broadleaf | 15-30m | Community acceptance | $140K-$200K |

| National Park | Context-specific | 20-40m | Environmental impact review | $170K-$250K |

| Desert Region | Saguaro cactus | 15-25m | Specialized design | $135K-$190K |

| Historical District | Clock tower/Flagpole | 10-25m | Preservation board approval | $130K-$210K |

Installation and Maintenance Requirements

Construction complexity increases significantly with camouflage elements.

Installation Timeline Standard monopole: 3-5 days for complete installation Camouflage monopole: 5-8 days for complete installation

The additional time comes from:

- Bark installation on pole segments

- Branch assembly and attachment

- Quality inspection of aesthetic elements

- Alignment verification ensuring proper coverage

Foundation Requirements Branch weight adds 20-35% to tower weight depending on design. Foundation engineering must account for this additional load plus increased wind loading from branches.

Soil conditions matter more for camouflage towers. Marginal soil that might work for bare monopoles often requires foundation enhancement for camouflaged versions.

Our design team at X.Y. Tower reviews geotechnical reports before finalizing foundation specifications. This prevents expensive surprises during construction.

Initial Quality Inspection Post-installation inspection verifies:

- All branches properly secured and aligned

- Bark coating complete with no exposed steel

- Antenna concealment effective from ground view

- Structural connections properly torqued

- Grounding systems functional

- RF performance meeting specifications

Maintenance Schedule Years 1-5: Visual inspections annually. Check for branch damage, coating degradation, structural issues.

Years 5-10: First major refurbishment. Replace damaged branches. Touch up bark coating. Structural integrity assessment.

Years 10-20: Ongoing maintenance cycles. Budget for significant branch replacement or complete re-camouflaging depending on material quality.

Years 20-30: End-of-life planning. Evaluate complete tower replacement vs. continued maintenance.

Drone Inspection Capabilities The latest TIA-222-I standard recognizes drones as acceptable inspection tools. This significantly reduces inspection costs for tall towers by eliminating some climb requirements.

Drone inspection works particularly well for camouflage towers where visual assessment of branch condition can be conducted remotely, reserving climbing for actual repairs.

Why X.Y. Tower for Your Camouflage Tower Project

Our 17 years of manufacturing experience extends across power transmission, telecommunication infrastructure, and specialized structures. That breadth gives us unique perspective on camouflage tower engineering.

Design Capability We use ANSI/TIA-222-G-2 certified software for structural analysis, ensuring every design meets international standards before fabrication begins. Our engineering team has completed projects across diverse environments—from tropical coastal installations to high-altitude mountain deployments.

This experience informs design decisions. We know which approaches work reliably and which create maintenance headaches years later.

Manufacturing Quality Our 40,000-ton annual production capacity supports projects from single towers to complete network deployments. Ten automated production lines maintain consistent quality across all components.

ISO 9001 certification means documented, repeatable processes. Every weld, every coating application, every assembly step follows verified procedures. The result: towers that perform as designed for their full 30+ year lifespan.

Integrated Galvanizing Our dedicated HDG factory in Guanghan handles all galvanizing in-house. We control the process rather than relying on third-party facilities. This ensures coating thickness consistently exceeds minimums and allows us to optimize the galvanizing process for tower components specifically.

Hot-dip galvanizing isn't negotiable for towers. The difference between proper galvanizing and inadequate protection shows up in 5-10 years as rust damage. Our process eliminates this risk.

Global Project Experience Since 2017, we've exported to 20+ countries across Africa, Southeast Asia, South America, and Europe. Different regions bring different requirements—environmental conditions, regulatory frameworks, aesthetic expectations.

This diversity strengthens our designs. Solutions that work globally are inherently robust.

Full-Service Support From initial design consultation through fabrication, delivery, and installation support, we provide comprehensive project management. Our team coordinates with your local contractors to ensure smooth execution.

Questions don't wait for business hours. Our technical support team responds rapidly to site challenges, providing solutions that keep projects on schedule.

Frequently Asked Questions

Monopine towers use evergreen branch designs suited for temperate and northern climates, while monopalm towers feature flexible frond elements designed for tropical and coastal regions. Monopines typically support heights from 15-50 meters versus 20-45 meters for monopalms. The core structural engineering remains similar; the difference lies in camouflage elements matching regional vegetation. Choose based on what trees actually grow in your project location.

Camouflage typically adds $100,000-$150,000 to standard monopole construction costs for a 30-meter tower. This premium covers RF-transparent branches ($2,500-$3,500 per meter), UV-resistant bark coating ($15,000-$25,000), structural reinforcement to support additional weight ($12,000-$18,000), and increased installation complexity. While significant, this investment often proves worthwhile by reducing permit approval time by 40-60% in aesthetically sensitive areas.

Yes. Every camouflage tower must comply with TIA-222-H/I structural standards, ASCE 7-22 loading criteria, and local building codes. The galvanized steel monopole core provides identical structural integrity to conventional towers. Camouflage elements add aesthetic value without compromising safety, wind resistance (80+ mph survival), or antenna capacity. Our ISO 9001 certified manufacturing process ensures both standard and camouflaged towers meet identical quality benchmarks.

Quality camouflage materials provide 20-30 years of service life with proper maintenance. UV-resistant HDPE branches maintain flexibility and strength for decades when manufactured to specification. Hot-dip galvanized steel cores last 30+ years with minimal maintenance. Bark coatings may require touch-up painting every 10-15 years depending on climate severity. Budget for branch refurbishment around year 10-15 to maintain aesthetic quality throughout the tower's operational life.

Retrofitting is possible but requires structural analysis to verify the monopole can support additional branch weight and wind loading. Many existing towers lack adequate structural capacity for full camouflage retrofits. Partial camouflage (concealing only antenna sections) sometimes works as a compromise. Complete retrofits often cost nearly as much as new construction after accounting for structural modifications, making replacement more cost-effective for towers approaching end-of-life. Our engineering team can assess retrofit feasibility for your specific tower.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.