Custom-Built Power Monopoles: Xiangyue’s 100-Ton Breakthrough in Philippines

2025-05-09

——Cross-Border Delivery of 110kV Monopoles Marks New Chapter in Southeast Asian Market

Recently, Xiangyue Power Group, a leading Chinese power equipment manufacturer, announced the successful delivery of its first overseas monopole project—the 110kV power monopole project for a Philippine company. With a total weight of nearly 100 tons, this milestone signifies a critical step in Xiangyue Power’s strategic expansion into the Southeast Asian market. It also serves as another example of Chinese enterprises leveraging technological prowess to access high-end international markets under the Belt and Road Initiative.

Rigorous Demands Drive Customized Collaboration: A Two-Way Journey from Blueprint to Product

The purchaser of this project is a renowned Philippine company specializing in power infrastructure. Its 110kV transmission line project imposed stringent requirements on structural strength, corrosion resistance, and installation efficiency for the monopoles. After multiple rounds of technical negotiations, Xiangyue Power emerged as the chosen Chinese supplier for the first-time collaboration, thanks to its expertise in power pole manufacturing and service reputation.

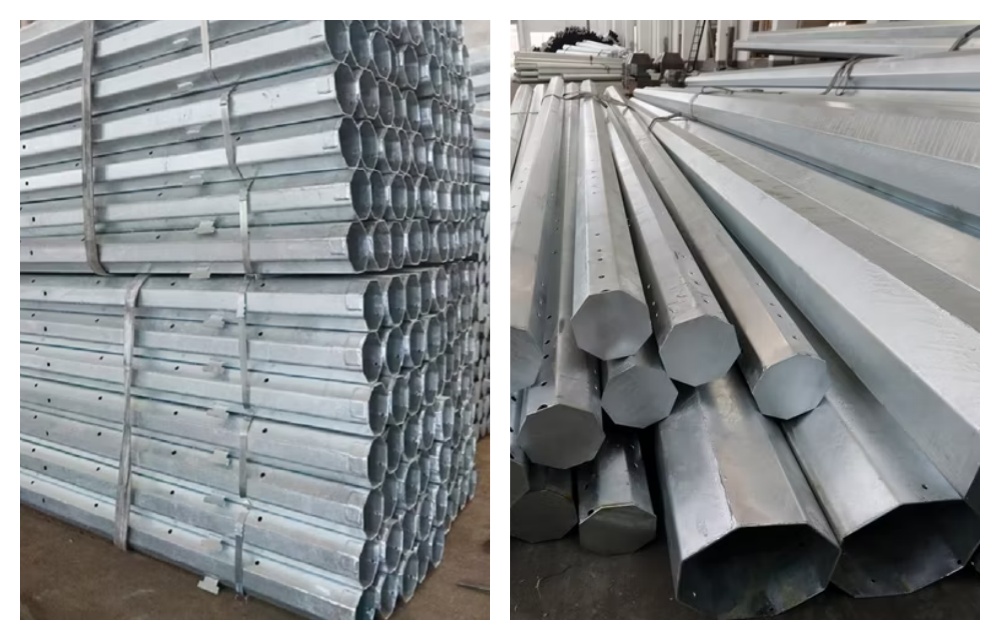

The core product of the project is the 110kV monopole, which utilizes a hybrid design of Q355B and Q235B steel to balance high strength and cost-effectiveness. To address the tropical marine climate of the Philippines—characterized by year-round high temperatures, humidity, and salt spray—Xiangyue’s technical team innovated a "differentiated hot-dip galvanizing process." The main body of the pole features an 86μm zinc coating, while critical connection points are reinforced with a 120μm layer, far exceeding the ISO 1461 international standard. This ensures over 30 years of corrosion resistance. Additionally, modular design principles were incorporated, with standardized flange connections to significantly reduce on-site installation time, aligning with the client’s demand for engineering efficiency.

Notably, the collaboration underwent a six-month technical磨合 period. “The client demanded specifications exceeding industry norms, including wind load calculations, seismic resistance, and bolt hole tolerance,” revealed Xiangyue Power’s head of international operations. The project team revised design drawings 27 times and conducted three wind tunnel simulations with North China Electric Power University, ultimately boosting the monopole’s wind resistance to 60m/s—perfectly suited for the Philippines’ typhoon-prone environment.

From "Made in China" to "Intelligent Manufacturing in China": Xiangyue Power Polishes Its Global Brand

As one of the few domestic companies with full industrial chain capabilities in power pole production, Xiangyue Power’s delivery of this project not only demonstrated efficient cross-border collaboration but also highlighted Chinese enterprises’ competitiveness in high-tech power equipment.

“International clients’ demands have accelerated our technological upgrades,” stated Xiangyue Power’s chief engineer. During R&D, the company deployed BIM 3D modeling for visual design and utilized intelligent welding robots to achieve a 99.8% first-pass weld qualification rate. A blockchain traceability system was also introduced, enabling transparent management from raw material procurement to finished product delivery. This allowed the Philippine client to track production progress and quality data in real time.

The Philippine project director praised the outcome during inspection: “Xiangyue’s team transformed our vision into reality with professionalism. These monopoles are not just engineering materials but artworks integrating innovative technology.” The project’s success is expected to bolster grid upgrades in Luzon, enhancing power stability for over 500,000 residents.

Deepening Belt and Road Ties: Xiangyue Power Targets Global Markets

The delivery of this 100-ton monopole project marks a pivotal milestone in Xiangyue Power’s global strategy. In recent years, the company has obtained international certifications such as EU CE and U.S. ASCE, while executing benchmark projects in Vietnam, Indonesia, and other Southeast Asian countries. By 2023, its overseas revenue share surged to 35%, reflecting a 120% year-on-year growth.

At the project debriefing, Xiangyue Power’s chairman declared: “Starting with the Philippines project, we will establish a Southeast Asia Technical Service Center to provide full lifecycle services—from design consultancy to operational guidance—letting more nations witness the quality and efficiency of Chinese power equipment.”

Industry experts note that as global energy transitions accelerate, demand for power infrastructure construction and upgrades is soaring. Xiangyue Power’s overseas strategy—centered on technical customization, intelligent production, and localized services—offers a replicable model for Chinese power equipment firms expanding internationally. With two decades of industry experience, this enterprise may soon illuminate global power grids with more “China solutions.”

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.