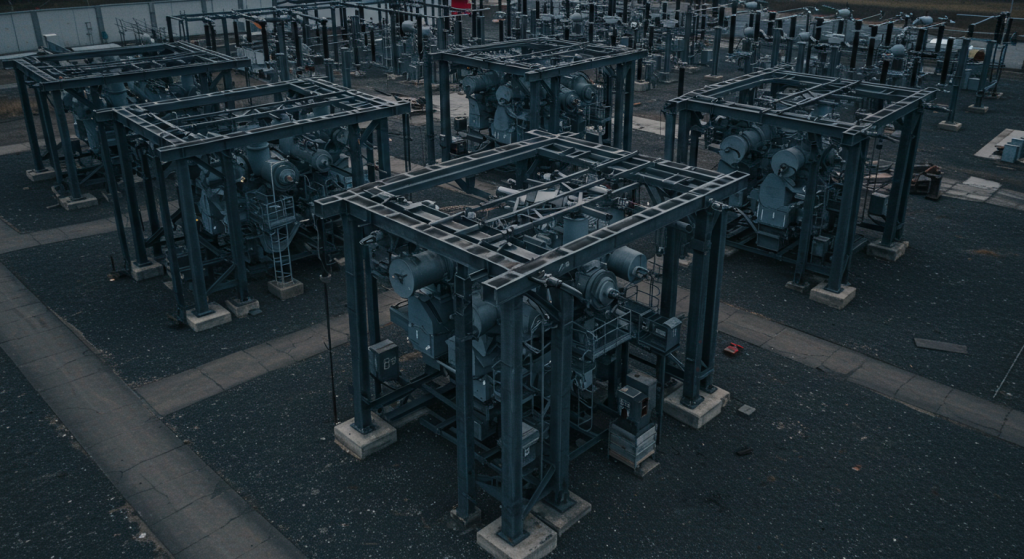

Custom Welded Substation Structures Q355/Q420 Applications

2025-07-21

Why Q355 & Q420 Steel?

Modern substations require attention to the materials used for performance, safety features, and operational lifespan. Here, one of the safest structural steels to use is custom welded substation structures Q355/Q420, which are captured in GB/T 1591-2008, China’s standard on high-strength structural steel.

Balanced Strength and Weldability: Q355

It provides a yield strength of ≥355 MPa, tensile strength of 490-630MPa, and elongation can go up to 20%. Q355 is famous for its weldability, which allows economical construction of welded substation gantries, equipment platforms, and moderately loaded structures. It also helps promote economic manufacturing while maintaining check here structural integrity and reducing construction costs.

Higher Yield, Greater Toughness: Q420

About Q355, Q420 gains an additional 20% yield strength to ≥420 MPa with a tensile strength of 520-680MPa. This strength is a result of a lower alloyed carbon-manganese composition that improves impact and fatigue resistance. Q420 is appropriate for heavy-load towers and is also utilized in seismic and other extreme conditions.

Fabrication of Substation Structures and Q355/Q420 Welding Norms

Welding is the main focus for the load-bearing subsystems. For the custom welded substation structures Q355/Q420, both safety and performance are crucial. Precise welding helps in building strong structures with high load-bearing capacity and durability.

Substation Structures Certified Welding Standards

Welded substation structures of fully custom design are made to comply with ISO 3834 and AWS D1.1, which are two international standards for the consistency and quality of welding that fully cover the scope. These standards specify materials to be used, their qualifying welders and procedures, as well as post-weld treatments.

Welding Techniques Employed for Q355/Q420 Substation Structures

The choice of welding techniques for Q355/Q420 substation structures is of paramount importance. From a construction perspective, the completion of this project requires skeleton accuracy, seam welding precision, and robust weight-bearing capability. For these criteria to be met, a combination of three expert welds based on engineering requirements, material thickness, and joint type is required.

MIG Welding (Metal Inert Gas)

Due to speed, cleanliness, and efficiency, MIG welding is suitable for mid-range Q355 or Q420 steel parts. It's something Iris and Professor. Self-adhesive sachets attached to utility belts, which contain microchips and other specialized equipment, can be carried. Moreover, Q355 frames can be stored in specially designed drawers, which are space-saving and can hold other essential equipment parts.

TIG Welding (Tungsten Inert Gas)

TIG welding works best on thin Q355 steel parts due to its capability of working close to delicate substation parts. The process of joining these parts yields strong and neat welds but requires a skilled worker.

SAW (Submerged Arc Welding)

Q420 structural components, such as transmission towers and other seismic-load framed parts, are heavy-duty. Their welds require deep penetration, which is a distinct advantage of SAW.

Following these methods ensures full strength and reliability because compliance with welding standards such as AWS D1.1 and ISO 3834 provides partial strength while relying on the method used for welding.

Non-Destructive Testing (NDT)

We use radiographic, ultrasonic, and magnetic-particle testing methods to inspect the welds, ensuring full internal and surface evaluation. Due to ISO 9001-certified production and stringent testing in place, our structures deliver superior mechanical strength and reliability.

Design Codes & Surface Treatment

The following criteria have been established as essential for the design of our frames:

• Compliance with IEC 61936 and ASTM A123/ISO 1461 for hot-dip galvanizing.

• Environmental load: wind, snow, seismic activities.

Common Substation Structures

1. Gantry Frames

Specialized structures that support overhead busbars and conductors. They require exceptional precision and load-bearing capability.

2. Support Towers

They can be constructed in folding plate or lattice forms. Critical for transformer and switchgear clearance, they are made from Q355/Q420 steel welded to AWS standards.

3. Equipment Platforms

Comprise steel decks and high-strength beams designed for the sustaining, grounding, and access functionality.

Technical Comparison: Q355 Vs Q420

The choice of steel grade significantly impacts the safety and operational effectiveness of custom welded substation structures, and while both Q355 and Q420 are high-performance structural steels, each provides differing benefits suitable to specific uses.

Yield & Tensile Strength

The steel used for the general-purpose substation support structures, Q355, has a yield strength of a minimum of 355 MPa and tensile strength of between 490 - 630 MPa, making it economically favorable. However, if greater structural stress and heavy load are expected, Q420 with a yield and tensile strength of ≥420 MPa and 520-680 MPa, respectively, would be more suitable.

Weldability & Fabrication

Good weldability of Q355 leads to faster fabrication and assembly procedures. Q420 covers some good weldability; however, stringent advanced welding practices are needed to guarantee adequate fusion of critical joints.

Corrosion Resistance & Applications

Both custom welded substation structures Q355/Q420 grades, gain advantages from galvanizing; however, Q420 exhibits better fatigue strength compared to Q355. From an economic perspective, Q355 is best used in standard platforms and gantries, while Q420 is more suited for high-load applications such as towers in seismic zones or critical grid points.

How to Choose the Right Grade

- Application Load: Q355 applies for moderate load applications; however, in heavy-duty and seismic load zones, Q420 would be more adequate.

- Welding Capacity: Working with Q355 is significantly easier than Q420 from a fabrication and welding perspective. In contrast, Q420 is more complex and requires specialized, skilled welding.

- Site Environment: With regards to harsh climatic conditions, Q420 does have better corrosion and fatigue resistance, which are distinct advantages.

- Budget & Schedule: In the case of Q420, costs and longer lead times are more apparent, while with Q355, speed and affordability work hand in hand.

Compliance & Export Assurance

We are holders of an ISO 9001 certification; all structures are manufactured in-house hot hot-dip galvanized to A123 or ISO 1461 Certification. Structures are tested to IEC 61936, ASTM A123/ISO 1461, and AWS D1.1.

Conclusion:

Achieving global industry benchmarks is demonstrated through compliance and export assurance. The mechanical properties of the materials and the specific welding technique used determine the engineering reliability and functionality of the grid infrastructure. For the structure, one can go with custom welded substation structures Q355/Q420. Both are adaptable for power infrastructure. However, Q355 is more weldable and offers better balanced strength than Q420, which stands out in yield and durability, particularly in harsh environments. XY Tower guarantees build-to-order and custom-welded substations with compliant performance for GB/T, ISO, IEC, and ASTM standards

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.