How Much Does a Mobile Antenna Tower Cost to Buy?

2025-12-11

In 2026, buying a mobile antenna tower directly from a manufacturer typically costs between $15,000 and $50,000 for the steel structure itself. However, a full turnkey installation (including land, foundation, labor, and electrical) can range from $150,000 to over $350,000. Sourcing directly from manufacturers like XY Tower can save you 30-50% compared to local resellers, who often mark up prices significantly.

Why This Matters

If you are expanding a telecommunications network, setting up a private 5G network for a factory, or upgrading rural connectivity, the cost of the tower is likely your biggest concern.

In 2024 and 2025, the demand for mobile towers has skyrocketed. This is driven by the global rollout of 5G and the need for "densification"—placing more towers in smaller areas to handle high data traffic. For purchasing managers and construction contractors, understanding the real cost breakdown is critical.

Buying a tower isn't just about the steel price. It involves understanding wind loads, galvanization quality, and logistics. Making the wrong choice can double your costs or leave you with a rusting structure in five years. This guide breaks down exactly what you should expect to pay and how to get the best value.

Types of Mobile Antenna Towers and Their Costs

The price of a tower depends heavily on its design. Different shapes require different amounts of steel and engineering.

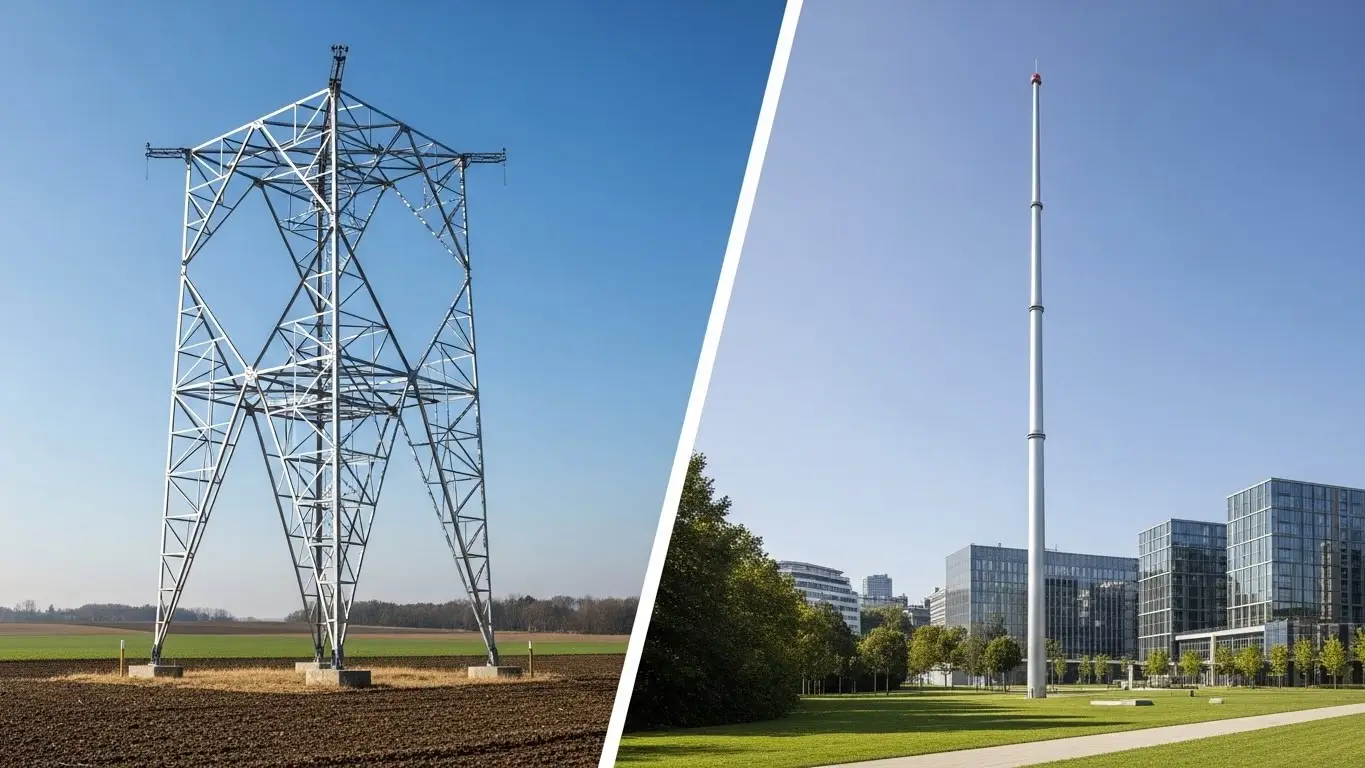

Lattice Towers (Self-Supporting)

These are the most common towers you see. They have three or four legs and use a triangular or square base.

- Best For: Heavy loads, high winds, and multiple tenants (many antennas).

- Estimated Cost (Structure Only): $25,000 – $65,000.

- Why: They use more steel but are incredibly stable. Lattice guyed towers are a variation that uses wires for support, often costing less in materials but requiring more land.

Monopole Towers

These look like single, large tubes or poles. They are popular in cities because they take up less space.

- Best For: Urban areas, strict zoning laws, and smaller sites.

- Estimated Cost (Structure Only): $20,000 – $55,000.

- Why: Manufacturing them requires specialized plate bending machines, which can slightly increase the cost per ton compared to simple angle steel.

Camouflage (Stealth) Towers

These are designed to look like pine trees, palm trees, or flagpoles.

- Best For: Scenic areas, residential neighborhoods, and parks.

- Estimated Cost (Structure Only): $40,000 – $100,000+.

- Why: You are paying for the "bionic" bark and leaves, plus the complex engineering to hide the antennas.

Cost Comparison: Manufacturer vs. Reseller vs. Rental

One of the biggest secrets in the industry is where you buy your tower. Most local suppliers in the USA or Europe do not make the towers; they import them and add a markup.

Here is how the pricing compares in 2025:

| Buying Channel | Est. Cost (100ft Lattice Tower) | Pros | Cons |

| Direct Manufacturer (e.g., XY Tower) | $20,000 - $35,000 | Lowest price, custom design, factory direct quality control. | Shipping takes 4-6 weeks; you handle import logistics. |

| Local Reseller | $50,000 - $80,000 | Immediate availability (sometimes), local support. | Huge markup (30-50%), limited customization. |

| Rental (Mobile COW) | $3,000 - $5,000 / month | Good for short-term events or emergencies. | Extremely expensive long-term (1 year = $36k+). |

Insight: If you need a tower for more than 10 months, buying a new one directly from a manufacturer is often cheaper than renting a temporary one.

Detailed Cost Breakdown: Where Does the Money Go?

When you see a quote for a tower, it helps to know what you are paying for. Here is the typical split for a tower project.

The Steel Structure (20-30%)

This is the physical tower kit. The price fluctuates with the global steel market. In 2025, steel prices have stabilized, making it a good time to buy.

- Material: High-quality towers use Q355B or Q345B steel.

- Warning: Cheaper towers might use lower-grade Q235 steel, which is weaker and requires more weight to achieve the same strength.

Galvanization (Crucial for Longevity)

You cannot just paint a tower. It must be Hot-Dip Galvanized according to ISO 1461 standards.

- Process: The steel is dipped in molten zinc at 450°C.

- Cost: This adds about 10-15% to the raw steel cost but ensures the tower lasts 30+ years without rusting.

- XY Tower Standard: We ensure a zinc coating thickness that meets or exceeds international standards, protecting your investment from corrosion.

Foundation and Civil Works (30-40%)

This is often the most expensive part of the project.

- Soil Test: You need a geotechnical report to know if the ground can hold the tower.

- Concrete: A 50-meter tower requires a massive concrete base reinforced with rebar.

- Labor: Excavation and pouring concrete are labor-intensive.

Logistics and Shipping (10-15%)

If you buy direct from a manufacturer like us, the tower is shipped in standard 40ft containers.

- Efficiency: Lattice towers are "knocked down" (taken apart), so they pack very efficiently. A single container can often hold a full 50-meter tower, keeping shipping costs low.

How to Buy a Tower: A Step-by-Step Guide

Buying a mobile antenna tower is a process. Follow these steps to avoid delays and extra costs.

- Determine Your Needs: Determine how tall it needs to be, how much weight (wind load) it must support (e.g., 4 huge 5G panels or just 2 small microwave dishes?), and the wind speed in your area (Coastal areas need stronger towers).

- Choose the Type: Select between Monopole, Lattice, or Guyed based on your land availability. Review our telecom tower pricing buying guide to see which model fits your budget.

- Get a Manufacturer Quote: Contact a manufacturer directly. Provide them with your height and wind speed requirements. Ask for a "CIF" price (Cost, Insurance, and Freight) to your nearest port.

- Secure Permits: Take the engineering drawings provided by the manufacturer to your local council or zoning board. Do not pour concrete until you have the permit!

- Fabrication and Delivery: Manufacturing usually takes 2-4 weeks. Shipping takes 3-6 weeks depending on your location.

- Installation: Hire a local rigging crew. They will assemble the kit (like a giant erector set) and lift it into place using a crane.

Common Mistakes to Avoid

We have seen many buyers make costly errors. Here are the big ones:

- Buying "Pre-Galvanized" Steel: Some sellers offer cheap steel that was galvanized before it was cut and drilled. This means the cut edges are raw steel. They will rust immediately. Always demand Hot-Dip Galvanization AFTER fabrication.

- Underestimating Wind Load: A tower designed for 100km/h winds will fail in a hurricane zone (160km/h). Always tell your manufacturer your exact location so they can engineer it correctly.

- Ignoring the Foundation: A tower is only as strong as its base. Never skimp on the concrete or rebar quality.

- Focusing Only on Price: The cheapest tower might use thinner steel or poor welding. In telecom, reliability is everything. A collapsed tower costs 100x more than the money you "saved" on cheap steel.

Expert Tips for 2026

Industry experts and engineers recommend these strategies for the current market:

- Plan Ahead: Global shipping routes can be unpredictable. Ordering your tower 3 months in advance guarantees you get it on time and often saves on "rush" shipping fees.

- Order Spares: When ordering a kit, ask for 5% extra bolts and nuts. Dropping them in the grass during installation is common, and you don't want to stop work for a missing $2 bolt.

- Check Steel Grades: Ask for the "Mill Certificate" for the steel. Ensure it matches the specs (e.g., Q355). Reputable manufacturers will always provide this.

- Consider Future Expansion: If you think you might add more antennas later (for 5G or leasing to other carriers), buy a tower that is 20% stronger than you currently need. The extra steel cost is small compared to replacing the whole tower later.

Frequently Asked Questions

What is the average lifespan of a mobile antenna tower?

A well-maintained, hot-dip galvanized steel tower can last 30 to 50 years. The key factor is the quality of the galvanization. If the zinc coating is thick enough (86 microns or more), it protects the steel from rust even in humid or coastal environments.

Do I need a permit to install a tower on private land?

Yes, almost always. Even on private land, you must comply with local zoning laws, height restrictions, and FAA/aviation regulations. You will likely need to submit engineering drawings (which manufacturers like XY Tower provide) to your local building authority for approval.

Can I install a mobile tower myself?

No. Tower erection is dangerous and requires certified professionals. It involves heavy lifting, cranes, and working at dangerous heights. While you can buy the kit yourself to save money, you must hire a professional rigging crew for the actual assembly and installation.

What is the difference between a monopole and a lattice tower?

A monopole is a single tube, offering a smaller footprint and a cleaner look, making it ideal for cities. A lattice tower uses a triangular framework of steel angles. Lattice towers are generally cheaper, stronger, and easier to climb, but they take up more ground space.

How much does it cost to lease land for a tower?

If you are a landowner renting space to a telecom company, lease rates vary wildly. In rural areas, it might be $500 to $1,000 per month. In dense urban areas or high-traffic zones, land leases can range from $2,000 to over $5,000 per month.

Does the price of steel affect tower costs?

Yes. Steel is the primary material. Since steel is a global commodity, its price fluctuates. However, because manufacturers buy in bulk, they can often shield customers from small spikes. In 2025, steel prices are relatively stable compared to the volatility of previous years.

What is a "Turnkey" solution?

"Turnkey" means the provider handles everything: finding the site, getting permits, pouring the foundation, supplying the tower, and installing it. While convenient, it is the most expensive option. Buying the tower kit direct and hiring local labor is usually much cheaper.

Can I move a tower after it is built?

It depends. "Cell on Wheels" (COW) towers are designed to be moved. Standard lattice or monopole towers are permanent structures anchored in concrete. While you can unbolt and disassemble them, the concrete foundation cannot be moved, and the relocation cost is high.

Key Takeaways

- Direct Savings: Buying directly from a manufacturer like XY Tower costs $15k-$50k, saving 30-50% over local resellers.

- Total Project: Expect the full project (foundation + install) to cost $150k+.

- Quality Matters: Always specify Hot-Dip Galvanization and Q355 Steel to ensure a 30-year lifespan.

- Know Your Needs: Wind speed and load capacity (number of antennas) dictate the price more than height does.

- Plan Ahead: Allow 6-8 weeks for manufacturing and shipping to get the best price and avoid delays.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.