Monopole Tower Standards: How Do Different Countries Compare?

2025-05-16

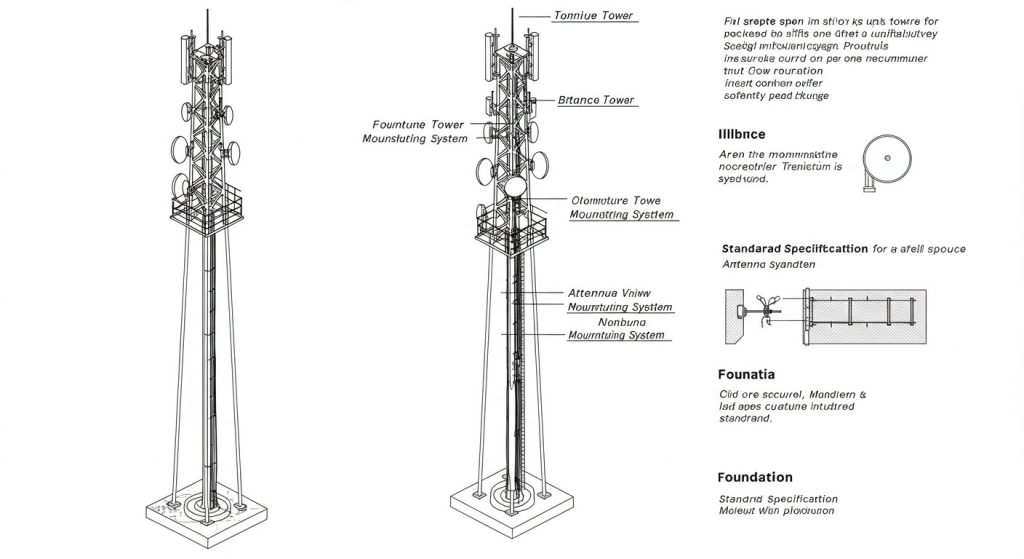

Monopole towers are widely used in telecommunications, street lighting, and power transmission due to their sleek design, ease of installation, and structural efficiency. However, their design and construction must comply with local engineering standards, which vary significantly across countries.

If you’re involved in manufacturing, installing, or purchasing monopole towers for international projects, understanding these differences is crucial. This blog compares key standards from the U.S., Europe, China, and other regions, covering wind/ice loads, materials, safety factors, and foundation design.

1. Wind and Ice Load Standards

United States (ANSI/TIA-222-G)

- Wind Load Calculation: Based on 3-second gust wind speeds, mapped by geographic zones.

- Ice Load: Up to 50mm ice thickness in high-risk areas (e.g., northern states).

- Key Feature: Combines wind and seismic loads for structural safety.

Europe (EN 1993-3-1, Eurocode 3)

- Wind Load: Uses 10-minute average wind speeds, adjusted for terrain and height.

- Ice Load: Typically 10-30mm, depending on location (e.g., Nordic vs. Mediterranean).

- Key Feature: Considers dynamic response for tall towers.

China (GB 50135-2019)

- Wind Load: Based on 50-year return period (10-minute average).

- Ice Load: 20-30mm in northern regions (e.g., Heilongjiang).

- Key Feature: Integrates seismic zoning from GB 50011.

India (IS 875 Part 3)

- Wind Load: Uses risk coefficients for cyclonic regions.

- Ice Load: Only applies to Himalayan zones.

- Key Feature: Focuses on tropical storm resistance.

Takeaway:

- U.S. standards are more conservative in wind load calculations.

- Europe emphasizes dynamic analysis for slender towers.

- China and India have regional-specific requirements for ice and cyclones.

2. Material and Corrosion Protection Standards

Steel Grades

| Country | Standard | Common Steel Grade |

|---|---|---|

| U.S. | ASTM A572/A36 | Grade 50 (345 MPa) |

| Europe | EN 10025 | S355 (355 MPa) |

| China | GB/T 1591 | Q345 (345 MPa) |

| India | IS 2062 | E350 (350 MPa) |

Galvanization Requirements

- U.S. (ASTM A123): Minimum 85μm (G90) coating.

- Europe (EN ISO 1461): Minimum 70μm (Class 1).

- China (GB/T 13912): Minimum 85μm (increased for coastal areas).

- Middle East: Often requires epoxy coating alongside galvanization.

Takeaway:

- Hot-dip galvanizing (HDG) is universal, but thickness varies.

- Coastal/high-corrosion zones (e.g., Gulf, Southeast Asia) need extra protection.

3. Safety Factors and Structural Design

Wind Load Safety Factors

| Standard | Safety Factor |

|---|---|

| ANSI/TIA-222 | 1.5 – 2.0 |

| Eurocode 3 | 1.35 – 1.5 |

| GB 50135 | 1.6 – 2.0 |

Seismic Design

- U.S. (ASCE 7): Earthquake zones mapped (e.g., California requires higher resistance).

- Europe (EN 1998): Uses seismic response spectra.

- China (GB 50011): Classifies regions into 6 seismic intensity zones.

Takeaway:

- U.S. and China apply higher safety margins.

- Eurocode allows more optimized (but complex) dynamic analysis.

4. Foundation Design Differences

- U.S.: Large concrete foundations with ASTM F1554 anchor bolts.

- Europe: Pile foundations in soft soil (EN 1997).

- China: Frost-proof foundations in northern regions (JGJ 94).

- Middle East: Reinforced bases for sandy/rocky terrain.

Takeaway:

- Soil conditions dictate foundation type.

- Permafrost (Canada/Russia) and seismic zones (Japan) need specialized designs.

5. Regional Adaptations & Certifications

- Europe: CE marking required.

- Middle East: GCC certification (Gulf Cooperation Council).

- India: BIS (Bureau of Indian Standards) approval.

- Brazil: NBR standards (similar to Eurocode but localized).

Tip: Always check local regulations—e.g., monopoles in Japan must comply with JIS C 8950 for typhoon resistance.

Conclusion: Key Takeaways for Engineers & Buyers

- Wind & Ice Loads:

- U.S. uses 3-second gusts, Europe/China use 10-minute averages.

- Ice loads vary from 10mm (Europe) to 50mm (U.S. northern states).

- Materials & Corrosion:

- Galvanization thickness differs (U.S./China: 85μm, Europe: 70μm).

- Coastal projects need extra protection.

- Safety Factors:

- ANSI/TIA and GB 50135 are more conservative than Eurocode.

- Foundations:

- Soil type and climate (frost, seismic, sand) dictate design.

- Certifications:

- CE (Europe), GCC (Middle East), BIS (India) are critical for compliance.

Final Advice

If you’re sourcing monopoles internationally:

✔ Specify the target country’s standards in procurement documents.

✔ Work with local engineers to validate designs.

✔ Consider corrosion protection based on environment.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.