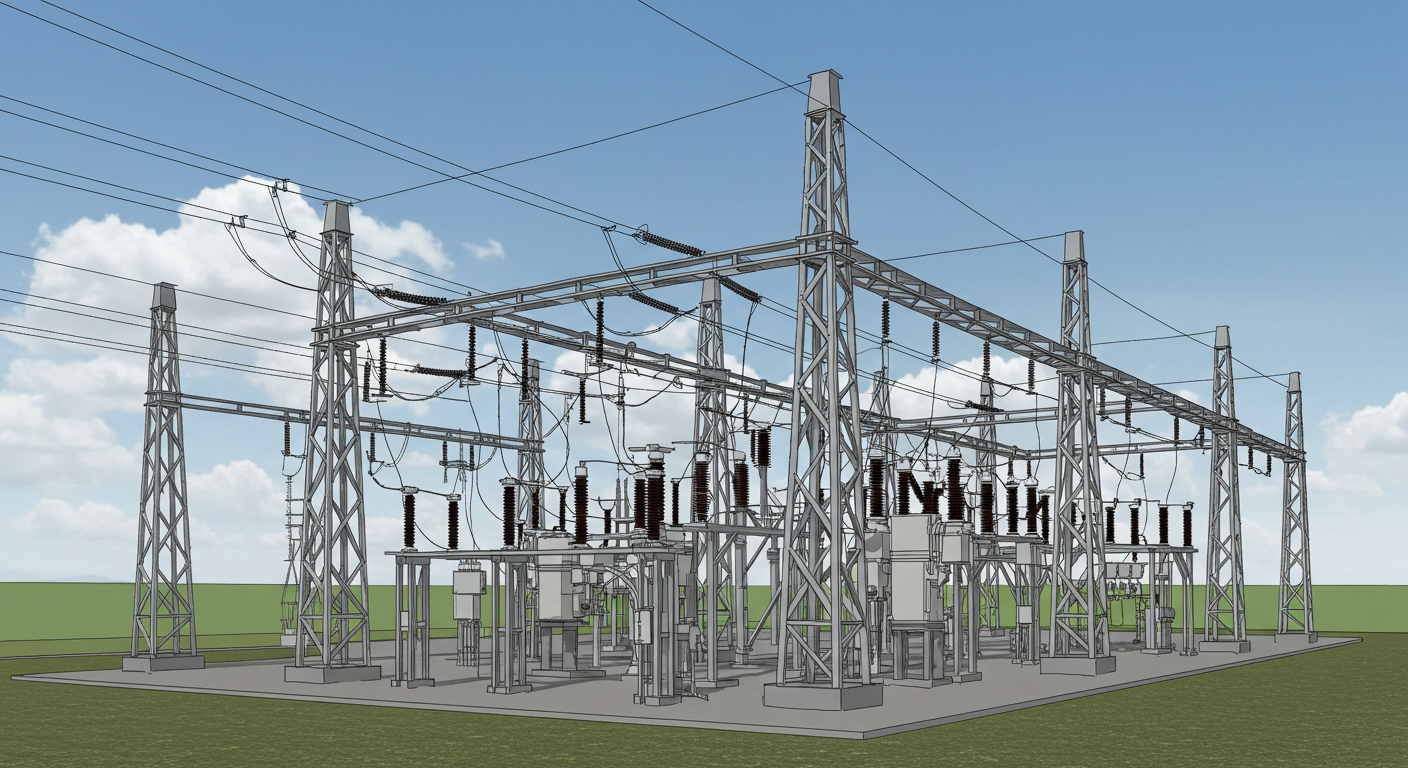

Steel Structure Substation

Our Steel Structure Substations offer reliable support for power equipment. Built with high-grade steel and corrosion protection, they ensure stability, safety, and long-term durability for substation operations.

- Service Type: Steel Structure Substation Design, Fabrication, and Installation

- Material Expertise: High-grade structural steel (Q235, Q355, Q420)

- Design Standards: ISO 9001:2015, AWS D1.1, ASTM standards

- Surface Treatment: Hot-Dip Galvanizing or Powder Coating

- Applications: Utility substations, industrial power distribution, and renewable energy projects

Overview

Our Steel Structure Substation is designed to provide strong, stable, and long-lasting support for high-voltage power equipment in substations. Constructed using high-strength structural steel, these substations ensure the proper alignment and secure positioning of transformers, busbars, circuit breakers, and switchgear. With excellent load-bearing capacity, wind resistance, and corrosion protection, they offer long-term durability in various environmental conditions. Customizable and modular designs allow them to fit different layouts and voltage requirements for power grids, industrial applications, and renewable energy installations.

- Durable Steel Construction: Designed using high-strength structural steel for superior load-bearing and long-term performance.

- Corrosion Resistance: Hot-dip galvanized or powder-coated finishes ensure protection against rust and environmental damage.

- Wind and Seismic Resistance: Engineered to withstand extreme weather conditions, including high winds and seismic activity.

- Customizable Configurations: Fully customizable to meet the substation’s layout and equipment requirements, including different voltage levels.

- Efficient Load Distribution: Optimized design ensures even load distribution, reducing stress and extending the service life of the structure.

- Modular Design: Pre-fabricated sections allow for quick and efficient on-site installation, minimizing project timelines.

- Safety Features: Includes grounding systems, lightning protection, and protective coatings to ensure personnel and equipment safety.

- Utility Substations: Providing stable support for power transmission and distribution equipment in utility networks.

- Industrial Power Systems: Facilitating stable power distribution within factories, heavy industrial plants, and mining operations.

- Renewable Energy Substations: Enabling efficient power distribution from solar, wind, and hydropower plants.

Our Steel Structure Substations undergo rigorous testing and inspections during design, production, and installation to ensure they meet international safety and structural standards.

Feature

Long-Lasting and Reliable Performance:

Constructed with corrosion-resistant materials and protective coatings, our steel structures are designed for long-term performance exceeding 30 years, even under harsh environmental conditions.

Optimized for Heavy Equipment:

Engineered to support transformers, circuit breakers, and busbars, our structures are optimized for efficient load distribution and long-term stability, reducing maintenance costs.

Safety and Compliance Focused:

We follow ISO9001:2015, AWS D1.1, and other international standards to ensure safety and stability. Integrated safety measures include grounding systems and lightning protection for additional security.

Efficient Installation and Maintenance:

Our modular designs ensure fast and efficient installation, reducing construction time and costs. The design also allows for easy access during maintenance and future upgrades.

Specification

| Details | Additional Information |

|---|---|

| Brand: Xiangyue (XY Tower) | Height Options: Customizable according to substation layout and voltage requirements |

| Service Offering: Steel Structure Substation Design, Fabrication, and Installation | Environmental Adaptability: Suitable for high winds, seismic zones, and outdoor conditions |

| Expertise: Specialized in steel structures for power grids, industrial substations, and renewable energy projects | Load Capacity: Engineered to support heavy electrical equipment like transformers, busbars, and switchgear |

| Design Standards: Adheres to ISO9001:2015, AWS D1.1, and ASTM standards | Certification: Meets international safety, quality, and structural certifications |

| Material Specification: High-grade structural steel, including Q235, Q355, and Q420 | Customization Level: Fully tailored to meet project-specific and site-specific requirements |

| Welding Standard: Certified AWS D1.1 welding procedures | Installation Assistance: Provides on-site guidance and modular assembly instructions |

| Surface Treatment: Hot-Dip Galvanizing or Powder Coating for corrosion resistance | Global Reach: Serving clients worldwide with tailored solutions for local regulations |

| Quality Control: Comprehensive inspections during design, production, and installation | Post-Design Support: Ongoing maintenance, upgrade services, and technical support |

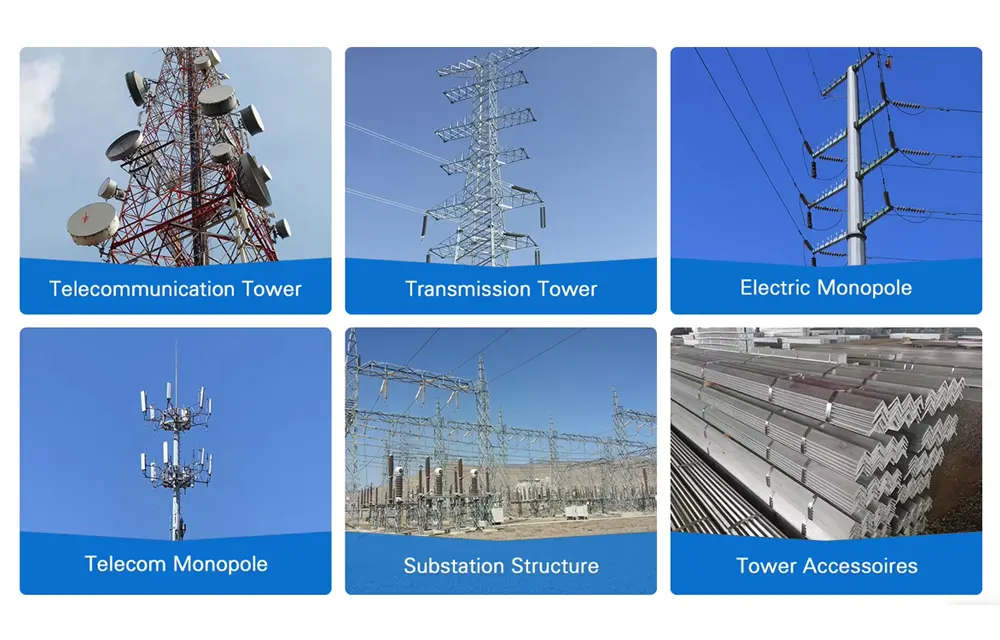

Related Resources

Transmission towers are critical components of electrical grids, supporting overhead power lines that carry electricity over long distances. These towers help maintain a steady flow of electricity from power plants ...

READ MORE

In the world of telecommunications, towers are integral components of the infrastructure that enables wireless communication systems. These towers come in various shapes, sizes, and designs, depending on the needs ...

READ MORE

XiangYue, officially known as SiChuan XiangYue Power Line Components Co., Ltd. (X.Y. Tower), is a comprehensive electrical power company that specializes in the design, manufacture, and supply of galvanized steel ...

READ MORE