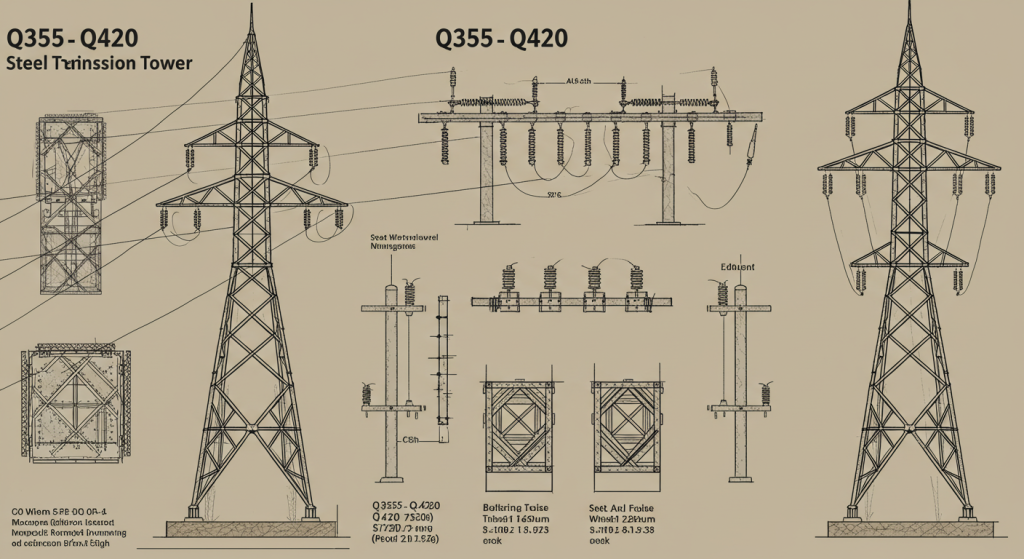

Q355 Q420 Steel Tower for Transmission Line

2025-07-17

Introduction

When it comes to power transmission, the strength and dependability of a tower are critical. The Q355 Q420 steel tower for transmission line is designed to endure harsh environments while remaining optimally efficient. Whether you are looking to install a power grid for the first time or if you are updating older infrastructure, selecting the correct steel tower is vital to your project.

This guide explains the materials, structures, and specifications of the benefits Q355 and Q420 steel towers offer. You will see how their high-strength weather-resistant steel composition makes these towers the top choice for modern long-distance high-voltage transmission lines.

What is a Q355 Q420 Steel Tower?

A Q355 Q420 steel tower for transmission line is a lattice-type steel tower. These towers have a lattice configuration and are intended for holding and supporting overhead power lines, particularly for long-span and high-voltage circuits. These towers utilize two high-grade steels, Q355 and Q420. They are both well-known for their mechanical strength, durability, and wind and seismic resistance.

Q355 steel is used for heavy structural work due to its high tensile strength. Q420 has an even higher yield strength along with greater stress handling capacity. The combination of the two makes the structure robust enough to allow a safe, uninterrupted flow of electricity through the system under extreme conditions like heavy storms.

Material Strength and Engineering Excellence

Q355 steel harbors a minimum yield strength of 355 MPa, which Q420 steel follows with a yield strength of 420 MPa. This remarkable strength and load-bearing capability fortifies the tower, making it suitable for bolting in high-voltage environments.

The towers endure additional layers of hot-dip galvanization, which further provide the structure with corrosion resistance, extending its lifespan to be functional in Coastal or desert regions. Following the steps of other countries, China issued its standards, ISO, GB/T, and IEC, marking the towers of world recognition for quality and performance.

Key Design Features

Lattice-Type Structure

The wind pressure on the construction is reduced due to the use of a lattice configuration, as the wind can pass through. This increases the aerodynamic performance stability in stormy or areas prone to typhoons.

Angle Steel and Tubular Designs

Using angle steel or tubular steel components, different types of towers can be manufactured that offer customized solutions according to the terrain, voltage level, and line span.

Optimized Cross-Arms and Bracing

Properly designed cross-arms maintain structural balance and can support multiple conductors, which reduces vibration and structural fatigue overall.

Tower Foundation and Anchoring

Foundation engineering plays an essential role for these types of towers, particularly for regions with soft soils or strong winds, as they are designed to resist uplift and overturning forces.

Modern Power Infrastructure Applications

High-Voltage Transmission Lines

For long-distance, high-voltage power lines, these towers serve as perfect support. They offer mechanical support and provide electrical clearance for several circuits.

Smart Utility Grid Systems

Towers are always needed to support new data and power-integrated systems, making the demand for smart utility grids higher. Q355/Q420 towers are known for their strong and stable performance.

Coastal, Mountain, and Desert Regions

These regions face harsh climate conditions and complicated terrain, but with strong foundations and corrosion resistance, these towers thrive.

Emergency & Disaster Recovery

These modular boxes can be quickly installed, making them ideal for temporary or emergency line recovery solutions.

Advantages of Q355 Q420 Steel Towers

• Enhanced Lifecycle: Designed for lateral wind and seismic forces

• Durability: Hot-dip galvanized coating for extreme climates

• Reduced Operational Expenses: Decreased chance of service repairs

• Strong Yet Lightweight: More efficient transport and rigging

• Customizable: Angle steel, tubular, or hybrid designs

• Sustainable: Minimal energy usage and recyclable construction materials

Compliance and Quality Assurance

Before shipping, we conduct thorough inspections on each tower. Our compliance regulations and industry certifications include:

• GB/T 1591 (Steel Standards)

• ISO 9001:2015 (Quality Management)

• IEC 60826 (Standards for the Design of Overhead Transmission Lines)

In addition, long-term structural integrity, material certification for components, as well as corrosion-resistant assays for components, are performed to ensure lasting durability.

Manufacturing and Installation Process

1. Design & Customization

Meeting each requirement dictates the voltage level, physical condition of the geographic site, desired height of the tower, and possible environmental loads. Subsequently, CAD tools alongside 3D software generate the custom architectural designs; thus, precision plans must be developed at each stage.

2. Material Preparation

This phase includes sophisticated Q355 and Q420 steel processing such as cutting, punching, and bending with CNC and hydraulic equipment, which ensures consistent and precise results.

3. Welding and Assembly

In this stage, all parts are welded and pre-assembled based on the CAD blueprints. Structural integrity is maintained through rigorous quality checks. There is precision measurement of gaps for bolts and other components to ensure proper fit during assembly.

4. Galvanization

All parts made from steel are subjected to hot dip galvanization to form a protective zinc layer to prevent rust and corrosion. This will also increase the durability of the tower in challenging environmental conditions.

5. Packing & Delivery

After galvanization is completed, all parts are then packed, labelled, and consolidated for transport. Well-planned logistics guarantees that the shipment will arrive at the site on time and without damage.

6. Installation at the Location

Specialized members of the team complete the Installation stage and ensure that the towers are anchored, aligned, and tightened properly. After commissioning, the last tests are done to guarantee that there is no active movement and that all safety measures are documented.

Conclusion

The selection of a transmission line tower may influence the dependable operation of the grid throughout its lifespan. Q355 Q420 steel tower for transmission line is designed with the required strength and flexibility to withstand the environment while being cost-effective. Our towers are constructed to the project requirements while still meeting the designed worldwide standards, which makes them exceptional in transmission infrastructure. For customers desiring tailor-made high-end performance transmission towers, XY Tower provides reliable answers with tested design solutions and outstanding engineering support.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.