Q355 Q420 Substation Structure with ISO Certification; Strength & Safety

2025-07-18

An Overview

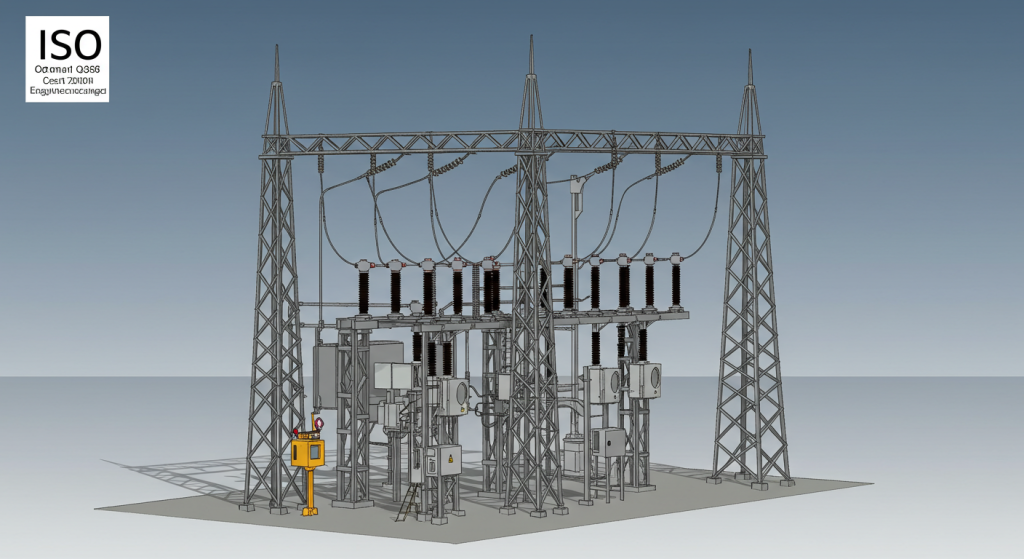

When it comes to substation structures, manufacturers require high-performance and certified quality, which makes today’s standards in the power industry critical. The most trusted materials used in the field include steel grades Q355 and Q420, due to their ever-reliable strength, long-lasting durability, and compliance on an international level. This guide will look at everything one needs to know about Q355 Q420 substation structure with ISO certification issued with ISO certification, which are best suited for power transmission, switchyard supports, and other electrical infrastructures.

What Does Q355 and Q420 Substation Construction Mean?

Q355 and Q420 refer to high-strength structural steels that come in different grades and are used for cross arms in electric power transmission lines; they are also used in the construction of voltage electrical substations. Each use of these materials justifies their versatility owing to their tensile performance, load-bearing capacity, and fatigue resistance.

• Q355 Steel: A low-alloy carbon steel that possesses a yield strength of 355 MPa. It is tough, weldable, and versatile.

• Q420 Steel: A high-strength alloy steel with a yield strength of 420 MPa, more resistant to impact and fatigue; performs better than Q355 in negative temperatures and harsh environments.

These steels are applicable for HV and MV substations on mechanical grounds, making them perfect for gantry structures, support beams, and tower legs.

Benefits of Mechanical Resistance in Substation Structures Q355 Q420

High Mechanical Strength

Severe winds and earthquakes are no match for these steel grades. In addition, they provide great structural integrity as well as thermal durability during prolonged operations.

Corrosion Resistance

Rust, humidity, and other pollutants encounter high levels of resistance when they come into contact with Q355 as well as Q420 substation structures due to hot-dip galvanization.

Weldability and Fabrication

Not only does CNC steel processing precision weld components and laser-cut steel members, but the fabrication processes also ensure that strict accuracy and high standards are maintained for the construction.

Compliance with ISO and IEC Standards

Under the certification of ISO 9001 and 14001, stainless steel parts can be produced, thus assuring environmental protection and safety for the structure.

Importance of Certification in Substation Infrastructure Q355 Q420

Quality Management System

ISO 9001 gives the friendly seal of a qualifying entity that the substations will manage to maintain set quality requirements during the entire life cycle of the product.

Environmental Compliance

With the issuance of an ISO 14001 certificate, the company undertakes an environmentally sustainable operation for its manufacturing through cutting back on waste and emissions generated.

Global Market Acceptance

Power structures that hold ISO and CE certifications will be accepted without question in any part of the world, making procurement easier and safer.

Typical Uses of Q355 Q420 Substation Structures

Substation Gantry Structures

Used for overhead busbars and conductors in switchyards.

Transmission Line Towers

These steels are suitable for the construction of the lattice towers used to support high-voltage transmission lines.

Electrical Grid Support

Used in alignment and safety systems of the electrical grid substation to ensure proper configuration and security.

Modular Steel Frames

Used in the assembled modular frameworks of substations for quick assembly and expansion.

Role of Substation Structures in Power Transmission

They are critical to the overall efficiency and reliability of power systems. They include the steel frames, which hold circuit breakers, transformers, and busbars, plus the substations that contain the control systems and safety equipment. Those are, however, not only components with static functions.

- They serve a dynamic role in routing, transforming, and delivering energy to ensure safety throughout the grid. Knowledge on architectural components of a substation, for example, its Q355 and Q420 structural steel, load-bearing foundation, and ISO assembly sheds light on power infrastructure and engineering innovation. Substation works are highly organized.

- They begin with the site design, materials to be used, grounding systems, and systems to mitigate corrosion and chemical degradation. Each part is built capable of withstand mechanical loads, environmental conditions, and decades of use.

The next time you drive past a substation, think about the strength and accuracy that meet your daily energy demands. These are not simply metallic structures; they form the hidden support for contemporary society.

Installation and Maintenance

Components like circuit breakers, transformers, and busbars must be properly anchored and aligned to enable the reliable and effective operation of the substation structures. Their installation and maintenance are of high precision. For long service life, each steel component, such as Q355 or Q420, should be flawlessly bolted together according to the substation layout design. Construction engineers check the material strength, connection interfaces, and grounding systems against ISO criteria and project requirements while monitoring the installation process. In case of any nonconformance, prompt site-specific remedial solutions tailored to the locality's geospatial and load conditions are essential.

The safety, efficiency, and longevity of substations rely on safeguarding their basic structures. Routine inspections and proactive measures aid in effectively rectifying possible faults.

• Foundation Inspection - It is imperative to monitor soil erosion as well as cracking, moving, and water damage for structural integrity.

• Structural Checkups - Components such as bracing and steel members like beams and columns require stringent monitoring for corrosive damage, welding, and overall fatigue.

• Coating Condition: Inspected galvanized surfaces require inspection for rust and peeling.

Scheduled maintenance actions for the substation help contain environmental fatigue alongside operational wear and tear, safeguarding continuous power flow.

Where to Purchase Q355 Q420 ISO Certified Substation Structures?

At XY Tower, we deal with high-grade substation parts manufactured from structural steels Q355 and Q420. We proudly hold all relevant manufacturing certificates, including ISO, ensuring compliance with utility standards across the globe. Contact us through our site to request quotations or ask for technical guidance.

Conclusion

Infrastructural steel used within substation assets directly influences failure risk, safety, productivity, and reliability during operation. Utilization of Q355 Q420 substation structures with ISO certification bolsters the perceived trust and demonstrated performance of these substations. Incorporating better mechanical characteristics together with ISO certification, and modular designed construction allows your substation to meet today's demands as well as prepare for future expansions. For more relevant information regarding substations components, regulatory benchmarks, and design details, follow XY Tower.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.