Railway Electrification Tower: Complete Guide for 2026

2025-12-22

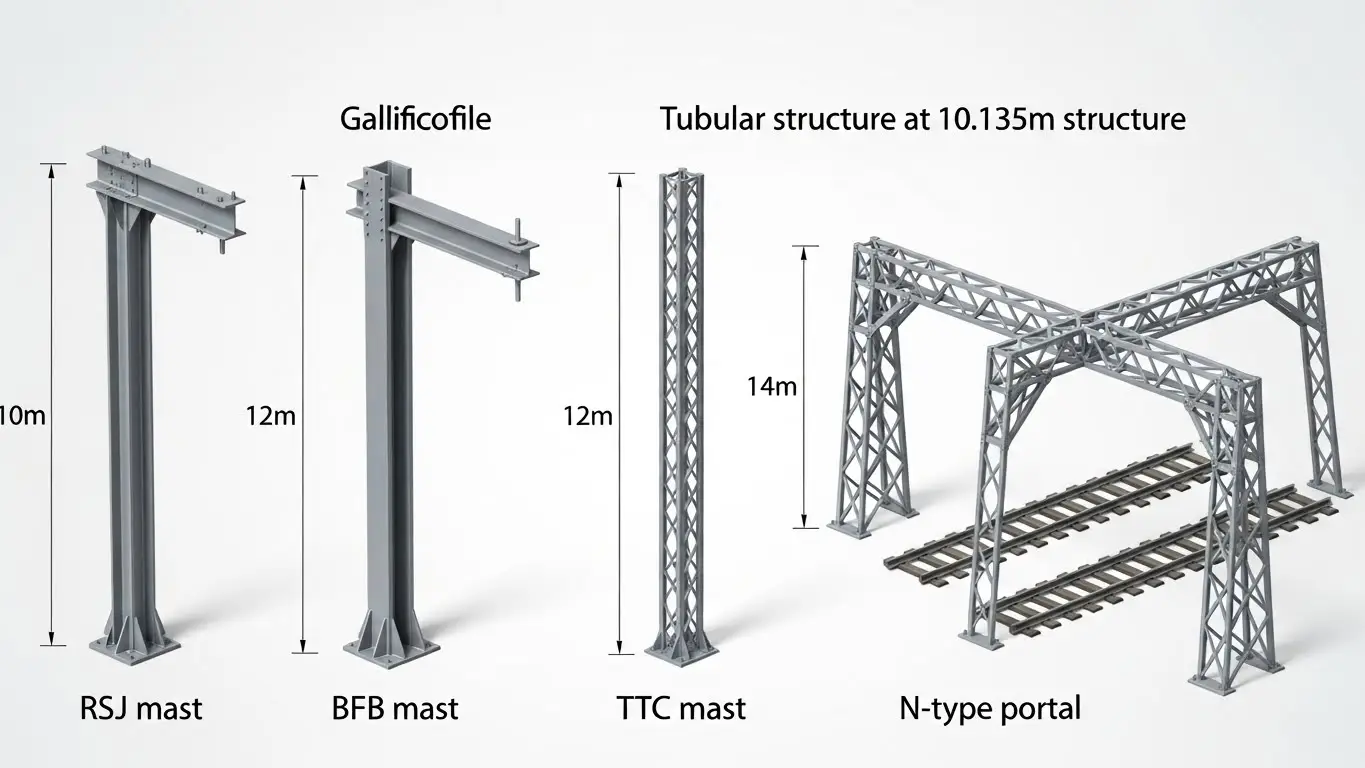

Railway electrification towers are hot-dip galvanized steel structures ranging from 10 to 15 meters in height that support overhead catenary systems (OHE) delivering 25kV AC power to electric trains. These structures include RSJ masts for curved tracks, BFB masts for straight sections, TTC masts at 10.135m standard height, and portal structures spanning 10-40 meters for multi-track configurations.

At X.Y. Tower, we've manufactured steel structures for railway electrification projects since 2008. Our 40,000-ton annual production capacity serves rail infrastructure projects across Africa, Southeast Asia, and South America.

The demand for railway electrification has surged. Electric trains cost 45% less to operate than diesel locomotives. They produce zero local emissions and enable regenerative braking that returns energy to the grid.

But here's what most procurement managers miss: selecting the wrong tower type for your track geometry creates maintenance headaches for decades.

What Makes Railway Electrification Towers Different?

Railway towers aren't just smaller transmission line towers. They're engineered for entirely different electrical and mechanical requirements.

The voltage matters. Railway systems operate at 25kV AC single-phase, while transmission towers handle 66kV to 800kV three-phase power. That difference dictates conductor arrangements, insulator specifications, and foundation designs.

Track curvature drives tower selection. RSJ (Rolled Steel Joist) masts handle the torsional forces on curves. BFB (Broad Flanged Beam) masts work on straight tangent tracks. Use the wrong type, and you'll see premature structural fatigue.

Our engineering team designs railway structures following RDSO specifications (ETI/OHE/53 series for Indian Railways) and international standards including BS EN 50163 and IEC 60850. After 17 years manufacturing towers, we've learned that proper material selection prevents 80% of field issues.

Types of Railway Electrification Towers

RSJ Masts (Rolled Steel Joist)

RSJ masts dominate curved track sections. The I-beam profile provides superior torsional strength needed when trains navigate curves while maintaining pantograph contact.

Standard heights range from 10 to 14 meters depending on track clearance requirements and local regulations. The hot-dip galvanization coating (minimum 610 GM/SQM) extends service life beyond 40 years.

BFB Masts (Broad Flanged Beam)

BFB masts are the workhorse of straight railway sections. The wide flange distributes vertical loads efficiently, making them ideal for tangent track where torsion isn't a concern.

These masts cost 15-20% less than RSJ masts while providing equivalent performance on straight routes. That savings adds up quickly on 100+ kilometer electrification projects.

TTC Masts (Tubular Twin Conductor)

TTC masts stand at 10.135 meters standard height with boom lengths of 5.5m or 8.0m. The tubular design offers cleaner aesthetics for urban rail lines and reduces wind resistance.

Manufacturing TTC masts requires precision CNC bending equipment. Our 16-meter CNC machines maintain tolerances within ±2mm across the entire structure, ensuring proper fit during installation.

Portal Structures for Multi-Track Sections

Portal structures span multiple tracks where independent masts aren't feasible due to track center restrictions. Three standard types serve different applications:

| Portal Type | Span Range | Track Capacity | Typical Application |

|---|---|---|---|

| N-Type | 10-20m | Up to 4 tracks | Medium rail yards |

| O-Type | 20-30m | Up to 6 tracks | Major stations |

| R-Type | 30-40m | Up to 8 tracks | Terminal complexes |

Portal structures require rigorous load analysis. The horizontal forces from multiple pantographs create complex stress patterns that standard tower designs don't address. Our design software (ANSI/TIA-222-G-2 compliant) models these loads to prevent structural failures.

Railway Electrification Standards You Need to Know

RDSO Specifications (Indian Railways)

RDSO (Research Designs & Standards Organisation) issues technical specifications for all railway equipment in India. Document ETI/OHE/53 covers OHE layout principles. Drawing series ETI/C/0310-0390 detail mast configurations.

CORE (Central Organisation for Railway Electrification) Part 1 certification verifies manufacturers meet these specs. Without it, you can't supply to Indian Railways projects. Period.

Material Standards

Steel must conform to IS-2062 or IS-808 for structural applications. International equivalents include:

| Standard | Region | Minimum Yield | Application |

|---|---|---|---|

| IS-2062 | India | 250 MPa | General structures |

| BS EN 10025 | Europe | 235-355 MPa | Railway structures |

| ASTM A36 | USA | 250 MPa | Steel structures |

| GB/T 700 | China | 235-390 MPa | Construction steel |

We source steel from certified mills only. Every batch includes mill certificates tracking material properties from billet to finished tower. That traceability matters during third-party inspections.

Galvanization Requirements

Hot-dip galvanization protects steel from corrosion for 40+ years. Minimum coating thickness is 610 GM/SQM per IS 2629. Premium applications specify 1000 GM/SQM.

Our in-house galvanizing facility uses 99.995% pure zinc in a 12.5-meter-long bath. We control bath temperature within ±5°C to ensure uniform coating. Most manufacturers outsource galvanizing, losing quality control at the critical final step.

Compare that to steel pole vs concrete pole construction—galvanized steel offers better strength-to-weight ratios and faster installation times.

25kV AC Railway Electrification System Explained

Modern railways use 25kV AC single-phase systems operating at utility frequency (50 or 60 Hz). This voltage became the global standard for good reasons.

Lower line current reduces conductor size. At 25kV, the current draw for a given power load drops to 1/16th of a 1.5kV DC system. Smaller conductors mean lighter structures and simpler foundations.

Feeder stations can space 50-80 km apart compared to 5-15 km for DC systems. That's fewer substations to build and maintain over a railway's lifetime.

Regenerative braking works more efficiently with AC systems. Trains returning energy to the grid during braking reduce overall power consumption by 15-20%.

The overhead catenary consists of two wires: a messenger wire (or catenary) supporting the contact wire below. The contact wire maintains consistent height using adjustable droppers, allowing the pantograph to collect current smoothly at speeds exceeding 300 km/h.

Selecting the Right Tower for Your Project

Track geometry determines tower type, but several other factors influence the final selection:

Wind speed zones affect structural loads. Coastal areas typically see higher wind pressures requiring heavier member sections. RDSO specifies design wind speeds from 150 to 180 km/h depending on region.

Span lengths between towers range from 22.5 to 72 meters in 4.5-meter increments. Longer spans reduce tower quantity but increase conductor loads and sag. The difference between consecutive spans shouldn't exceed 18 meters to maintain consistent flexibility.

Conductor configuration matters for high-capacity routes. Standard systems use single contact wires. Heavy traffic lines may deploy twin contact wires requiring different support arrangements.

Foundation conditions vary dramatically. Rocky terrain allows shallow foundations. Soft soils need deeper piling or ground improvement. We conduct site-specific geotechnical analysis to optimize foundation design.

For substation structures feeding railway systems, we apply similar engineering rigor to ensure reliable power delivery.

Manufacturing Process for Railway Towers

Quality railway towers require precision manufacturing from raw material to final delivery.

Material Receiving and Testing

Every steel shipment gets tested in our laboratory before entering production. We verify chemical composition, tensile strength, and elongation properties against specifications. Rejected materials go back to the mill.

CNC Fabrication

Our 10 automated production lines cut, punch, and bend steel with minimal human intervention. Computer control ensures each member matches design tolerances.

The 16-meter laser cutting machines slice through steel plates with ±0.5mm accuracy. CNC punching machines create bolt holes positioned within ±1mm across entire assemblies. That precision eliminates fit-up problems during erection.

Hot-Dip Galvanizing

After fabrication, towers get degreased, pickled in hydrochloric acid, and fluxed before immersion in molten zinc at 450°C. The metallurgical bonding creates a coating that doesn't peel or flake like paint.

We galvanize complete tower sections rather than individual members whenever possible. Fewer field connections mean fewer potential corrosion points.

Quality Control and Testing

Sample towers undergo full-scale testing to verify load capacity. Our test equipment can simulate wind loads, ice loads, and conductor tensions up to design limits plus safety factors.

Ultrasonic testing detects internal weld defects invisible to visual inspection. X-ray verification confirms critical welds meet structural requirements. Coating thickness gauges check galvanization at multiple points per member.

This quality system earned us ISO 9001:2015 certification and approval from railways across three continents.

Installation Considerations

Proper installation extends tower service life and reduces maintenance costs.

Foundation preparation starts weeks before tower erection. Pre-pegging plans mark exact tower locations based on track geometry and electrical sectioning requirements. Civil engineers verify soil bearing capacity and design appropriate foundations.

Earthing requirements call for resistance below 15 ohms at each tower location. We achieve this through copper earth strips buried at 0.6m depth connected to the tower base. Railway crossings require double earthing for enhanced safety.

Span management prevents excessive loads. Installation crews measure conductor sag at specified temperatures to ensure proper tension. Deviation from design sag exceeding 4% gets corrected before energization.

Clearance verification checks distances from the contact wire to track level, platforms, and nearby structures. Minimum clearances prevent arc-over and ensure safe maintenance access. Standards specify different clearances for AC vs DC systems.

Our tower design services include installation drawings that guide contractors through proper erection sequences.

Maintenance and Lifecycle Management

Railway electrification towers need less maintenance than many assume, but neglecting inspections invites problems.

Annual visual inspections catch obvious issues: loose bolts, damaged galvanizing, vegetation contact. A trained inspector can survey a 10-kilometer section in a single day.

Five-year structural inspections involve closer examination. Ultrasonic testing verifies member thickness at corrosion-prone locations. Bolt torque verification ensures structural integrity remains within design parameters.

Galvanization touch-up addresses minor coating damage from installation or accidental impact. Zinc-rich paint temporarily protects exposed areas until scheduled maintenance can apply hot-dip galvanizing.

Foundation monitoring tracks settlement over time. Uneven settlement creates undesigned stresses in tower members. Prompt remediation prevents structural damage.

Records matter. Maintaining detailed inspection logs helps identify trends before failures occur. Digital asset management systems now track individual towers across their 40+ year service life.

Cost Factors for Railway Electrification Projects

Tower costs represent 20-30% of total overhead electrification expenses. Several factors drive pricing:

Material quantities scale with tower height and load requirements. A 12-meter BFB mast uses approximately 1,200 kg of steel. Portal structures consume 3-5 times more material depending on span width.

Galvanization costs add 15-20% to base steel prices but eliminate recurring painting expenses. The payback period for hot-dip galvanizing versus painted steel is under 5 years.

Transportation expenses vary with project location. Containerization keeps shipping costs predictable for overseas projects. Domestic delivery uses standard trucking for distances under 500 km.

Installation labor depends on local wage rates and terrain accessibility. Flat, accessible routes install faster than mountainous or urban environments requiring specialized equipment.

Total project costs for railway electrification typically run $1-2 million USD per route kilometer including towers, catenary hardware, feeders, and installation labor. But that investment reduces operating costs by 45% versus diesel locomotives over the system's lifetime.

Railway Towers vs Transmission Towers: Key Differences

Many buyers confuse railway electrification towers with standard power towers. They're not interchangeable.

| Feature | Railway Tower | Transmission Tower | Why It Matters |

|---|---|---|---|

| Voltage | 25kV single-phase | 66-800kV three-phase | Insulator design differs |

| Height | 10-15m typical | 20-100m typical | Foundation requirements |

| Conductor arrangement | 2, 4, 8, or 12 | 3 or 6 (multiples of 3) | Structural configuration |

| Span length | 22.5-72m | 200-600m | Member sizing |

| Standards | RDSO/CORE/BS EN | IEC/IEEE | Certification path |

Railway towers face dynamic loads from moving pantographs that transmission towers never encounter. The mechanical interaction between pantograph and contact wire creates vibrations transmission tower designers don't consider.

Conversely, transmission towers withstand higher voltages requiring greater insulator lengths and clearances. Using transmission tower designs for railway applications wastes money on unnecessary strength.

Global Standards for Railway Electrification

Different regions specify different standards, but performance requirements converge:

India: RDSO specifications with CORE approval process. Largest railway electrification program globally with 100+ km being energized monthly.

Europe: EN 50163 and EN 50122 series cover voltage levels, clearances, and safety. Interoperability requirements allow trains to cross borders seamlessly.

North America: IEEE standards apply to limited electrified railways. Freight railroads remain largely diesel-powered, but Amtrak uses 25kV AC along the Northeast Corridor.

China: GB standards govern the world's largest high-speed rail network. Extreme operational speeds (350+ km/h) drive stricter catenary performance requirements.

Africa & Middle East: Mixed standards often based on colonial infrastructure. New projects increasingly adopt European specifications for equipment compatibility.

We manufacture to GB, EN, and ASTM standards depending on project requirements. Our design software handles conversions between standards systems automatically.

Environmental Benefits of Railway Electrification

Electric trains deliver tangible environmental improvements over diesel locomotives:

Zero local emissions benefit urban areas and tunnels. Passengers and nearby residents don't breathe diesel exhaust. That matters for public health in dense cities.

Energy efficiency improves 30-40% through regenerative braking. Trains descending grades or decelerating at stations return power to the overhead system rather than wasting it as heat in brake pads.

Renewable energy integration becomes feasible. Grid power can come from solar, wind, or hydro sources. Diesel trains can't run on renewables.

Noise reduction makes railways better neighbors. Electric motors operate more quietly than diesel engines. Trackside communities see noise levels drop 10-15 decibels after electrification.

Carbon footprint depends on the electricity source. Even coal-fired grid power produces less CO2 per passenger-km than diesel locomotives because centralized power generation operates more efficiently than thousands of small diesel engines.

Global railway CO2 emissions could drop 35% if all diesel routes converted to electric operation. The infrastructure investment pays environmental dividends for decades.

Common Mistakes in Railway Tower Procurement

After manufacturing towers for 100+ railway projects, we've seen buyers make predictable mistakes:

Specifying transmission tower designs for railway applications wastes 20-30% of the budget on unnecessary capacity. Railway-specific designs optimize material usage.

Overlooking galvanization quality creates lifecycle cost problems. Inferior coating wears through in 15-20 years versus 40+ for proper hot-dip galvanizing. Re-galvanizing towers in-place costs more than doing it right initially.

Ignoring local fabrication capabilities causes supply chain delays. Not every manufacturer can maintain the tight tolerances railway structures require. Our CNC equipment maintains precision that manual fabrication can't match.

Accepting generic certifications rather than railway-specific approvals blocks project approvals. Procurement managers need to verify manufacturers hold appropriate RDSO/CORE certifications before awarding contracts.

Skipping third-party testing to save a few percent on costs. Independent verification catches quality issues before towers ship. Fixing problems at the factory costs far less than dealing with field failures.

Future Trends in Railway Electrification

Railway electrification continues evolving:

Higher speeds push catenary technology. Contact wires must maintain precise geometry at 350+ km/h to prevent pantograph bounce. Tower designs need tighter tolerances and more robust attachments.

Battery hybrid systems reduce electrification infrastructure costs on lightly trafficked routes. Trains charge batteries under wires and operate 50-100 km on battery power through gaps.

Automated inspection using drones and AI vision systems reduces manual labor requirements. Thermal imaging detects electrical hot spots. LiDAR scanning measures contact wire position and wear.

Smart monitoring tracks structural health in real-time. Sensors measure tower movement, vibration, and strain. Predictive maintenance algorithms identify towers needing attention before failures occur.

Modular construction speeds installation on new routes. Pre-assembled tower sections with integrated wiring reduce field labor by 30-40% versus conventional stick-built methods.

At X.Y. Tower, we're investing in these technologies to stay ahead of changing specifications. Our engineering team collaborates with railway operators to understand emerging requirements.

Frequently Asked Questions

Railway electrification towers typically stand 10 to 15 meters tall, with TTC masts standardized at 10.135 meters. Portal structures reach greater heights depending on track configuration and clearance requirements. Height selection depends on contact wire positioning, local regulations, and terrain conditions.

Hot-dip galvanized railway towers with 610 GM/SQM minimum coating last 40+ years in typical environments. Coastal or industrial areas with corrosive atmospheres may require heavier 1000 GM/SQM coating. Proper maintenance extends service life to 50-60 years. Regular inspections and prompt repairs maximize longevity.

RSJ (Rolled Steel Joist) masts handle curved track sections requiring torsional strength, while BFB (Broad Flanged Beam) masts serve straight tangent tracks with primarily vertical loads. RSJ masts cost 15-20% more but prevent structural fatigue on curves. Using BFB masts on straight sections optimizes project costs.

Modern mainline railways use 25kV AC single-phase systems at 50 or 60 Hz. Urban metro systems often use 750V DC third rail or 1.5kV/3kV DC overhead systems. High-speed rail standardizes on 25kV AC globally. Voltage selection impacts conductor sizing, insulator requirements, and feeder station spacing.

Manufacturers require CORE Part 1 certification and compliance with RDSO specifications for Indian Railways projects. International projects need ISO 9001 quality certification plus material certifications for steel and galvanizing. Third-party testing verification from accredited laboratories validates product quality. Export projects may require additional country-specific approvals.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.