Rapid Deployment & Emergency Mobile Towers Solutions

2025-12-04

In disaster recovery operations or critical industrial projects, the difference between "offline" and "connected" is often measured in lives saved and millions of dollars in preserved assets. When terrestrial networks fail—or simply haven't been built yet—waiting weeks for concrete foundations and permanent infrastructure is not an option.

This is where Rapid Deployment Units (RDUs) bridge the gap.

Far more than simple trailers with antennas, modern rapid deployment mobile towers are sophisticated, integrated telecom nodes capable of restoring macro-level coverage in under two hours. Whether for restoring communications after a hurricane, providing temporary capacity for a massive event, or establishing a comms link for a remote mining exploration, these systems are the backbone of emergency response.

This guide provides a comprehensive engineering analysis of mobile tower solutions, covering structural selection, wind-load physics, power autonomy, and deployment logistics.

The Strategic Necessity of Rapid Deployment Units

In the telecommunications and industrial sectors, agility is the new currency. Traditional tower construction is a civil engineering project that takes months of permitting, soil testing, and curing concrete. An RDU compresses that timeline into minutes.

However, the application of these units extends beyond simple speed. They provide a strategic layer of redundancy for national security and business continuity.

Why the industry relies on RDUs:

- Disaster Recovery: Immediate restoration of GSM/LTE/5G signals when permanent towers are toppled by high winds or seismic activity.

- Interim Solutions: Providing coverage while a permanent site is being permitted or constructed (often called "gap-fillers").

- Special Events: Managing temporary surges in network traffic (e.g., festivals, sporting events) where permanent infrastructure cannot handle the load.

- Remote Industry: Establishing private LTE/5G networks for oil and gas sites before main power or fiber is available.

According to industry data, rapid deployment solutions utilizing pre-integrated setups can restore critical communications within 90 minutes of the vehicle arriving at the site access point.

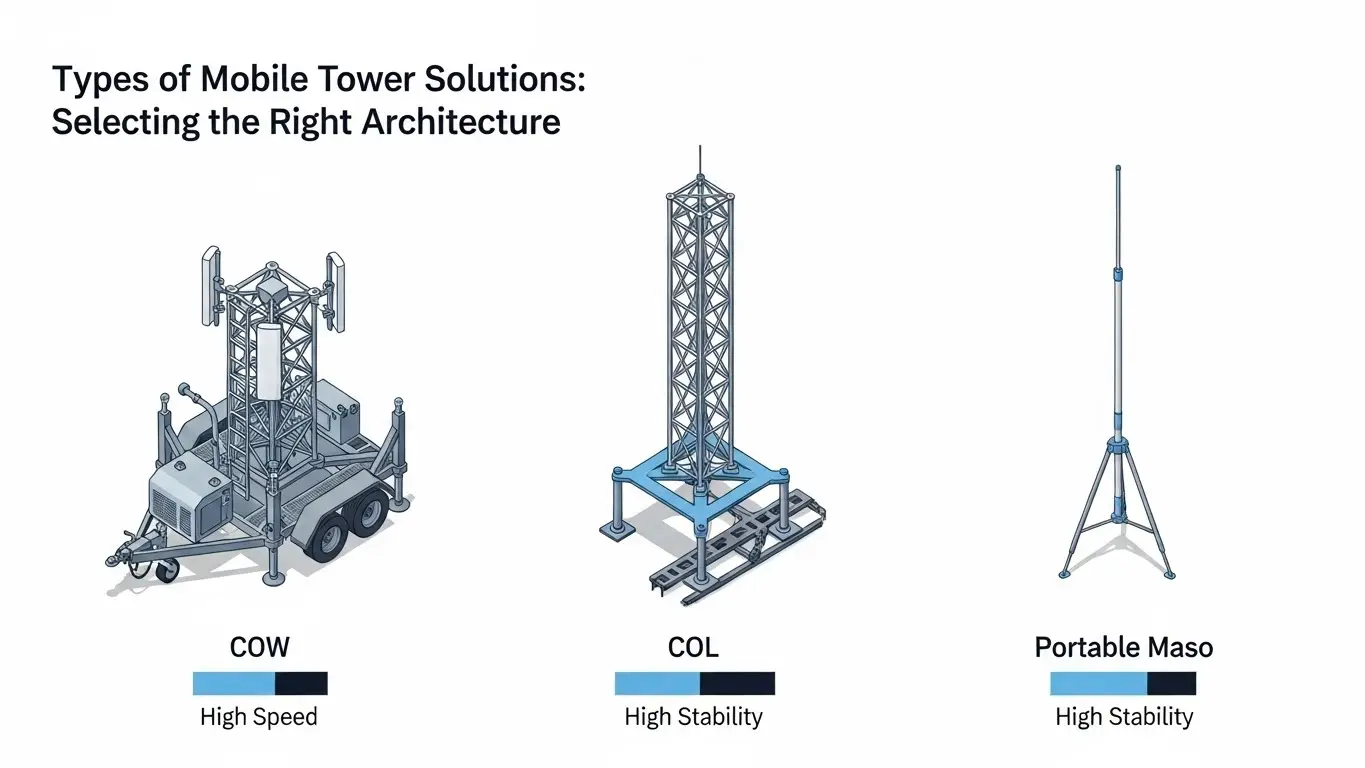

Types of Mobile Tower Solutions: Selecting the Right Architecture

Not all mobile towers are created equal. The choice between a Cell on Wheels (COW) and a Cell on Legs (COL) dictates the stability, footprint, and deployment speed of the operation.

Cell on Wheels (COW)

The COW is the industry standard for high mobility. Mounted directly onto a trailer chassis, these units can be towed by standard heavy-duty trucks. They utilize the weight of the trailer (and often additional water or concrete block ballasts) to counter the overturning moment of the mast.

- Best For: Short-term deployments (1-30 days), events, and locations with good road access.

- Key Advantage: Speed. Since the tower is permanently attached to the wheels, setup involves simply lowering outriggers and raising the mast.

Cell on Legs (COL)

Also known as a "skid" or "platform" solution, the COL is designed to be unloaded from a truck and left on-site. It stands on its own galvanized steel legs.

- Best For: Semi-permanent deployments (1-12 months), high-wind zones, and sites with limited footprints.

- Key Advantage: Stability and Security. Once the transport vehicle leaves, the tower is harder to steal or tamper with, and the footprint is often more rigid than a suspension-based trailer.

Rapid Monopoles & Trailer Masts

For lighter loads, such as Wi-Fi access points or surveillance cameras, pneumatic or mechanical telescoping masts offer a lightweight alternative. These are often integrated into smaller trailers or even hitch-mounted systems.

Engineering & Technical Specifications

When procuring or deploying a mobile tower, "height" is often the first specification requested, but "payload" and "wind rating" are the ones that dictate safety.

Height vs. Stability Physics

Mobile towers typically range from 10 meters to 40 meters (approx. 30ft to 130ft). As height increases, the center of gravity shifts, and the surface area exposed to wind increases the overturning moment.

Telescopic masts (nesting sections) are common for ease of transport. However, lattice towers (sections bolted together) offer superior rigidity for heavy microwave dishes that require precise alignment.

Wind Load Ratings: TIA-222 Standards

A mobile tower is only as good as its ability to stay upright in a storm. Established telecom tower manufacturers must adhere to TIA-222-G or TIA-222-H standards (Structural Standard for Antenna Supporting Structures and Antennas).

- Operational Wind Speed: The speed at which the antenna remains stable enough for the network to function (typically up to 80-100 km/h).

- Survival Wind Speed: The speed the structure can withstand without structural failure or overturning (typically 120-160 km/h, depending on guy wiring and ballast).

Tip: Always verify if the wind rating is "guyed" or "unguyed." An unguyed COW relies entirely on its chassis weight, while guy wires significantly increase stability but require a larger ground footprint.

Payload Capacity

The "head load" refers to the total weight of antennas, Remote Radio Units (RRUs), cabling, and mounting brackets at the top of the mast.

- Light Duty: < 100 kg (Surveillance, Wi-Fi)

- Medium Duty: 150 - 250 kg (Standard 3-sector cellular)

- Heavy Duty: > 400 kg (Multi-tenant setups, massive MIMO units)

Overloading a mast doesn't just risk bending the metal; it compromises the hydraulic lift system and drastically reduces the safe wind speed rating.

Power Autonomy: Keeping the Signal Alive

In emergency scenarios—especially post-hurricane—the commercial power grid is usually down. A mobile tower that relies on an external plug is useless in these environments. Modern RDUs must be self-sufficient energy islands.

Hybrid Power Integration

The most advanced RDUs utilize hybrid power systems to reduce maintenance trips and fuel costs.

- Diesel Generators (Gensets): The primary backup. A standard 10kVA to 20kVA generator can run the site, but running it 24/7 burns excessive fuel and requires frequent refueling trips.

- Battery Banks: Deep-cycle batteries (Lithium-ion or AGM) power the load during low-traffic periods or night hours.

- Solar Arrays: Fold-out solar panels on the trailer deck can trickle charge the batteries, extending the refueling interval from every 2 days to every 10-14 days.

Tip: For critical infrastructure, look for units with a "DC Generator" option rather than just AC, as telecom equipment runs natively on -48V DC, making the conversion more efficient.

Deployment Logistics and Setup

Deploying a mobile tower involves more than just driving to a site. It requires logistical planning to ensure the unit can physically access the location and operate safely.

Transportability

- Towing Class: Smaller masts can be towed by commercial SUVs. Heavy-duty 30m+ COWs usually require a dedicated truck with air brakes and a pintle hitch.

- Off-Road Capability: For mining or rural access, the trailer chassis must have high ground clearance and ruggedized suspension (torsion axles) to prevent vibration damage to the sensitive electronics on board during transit.

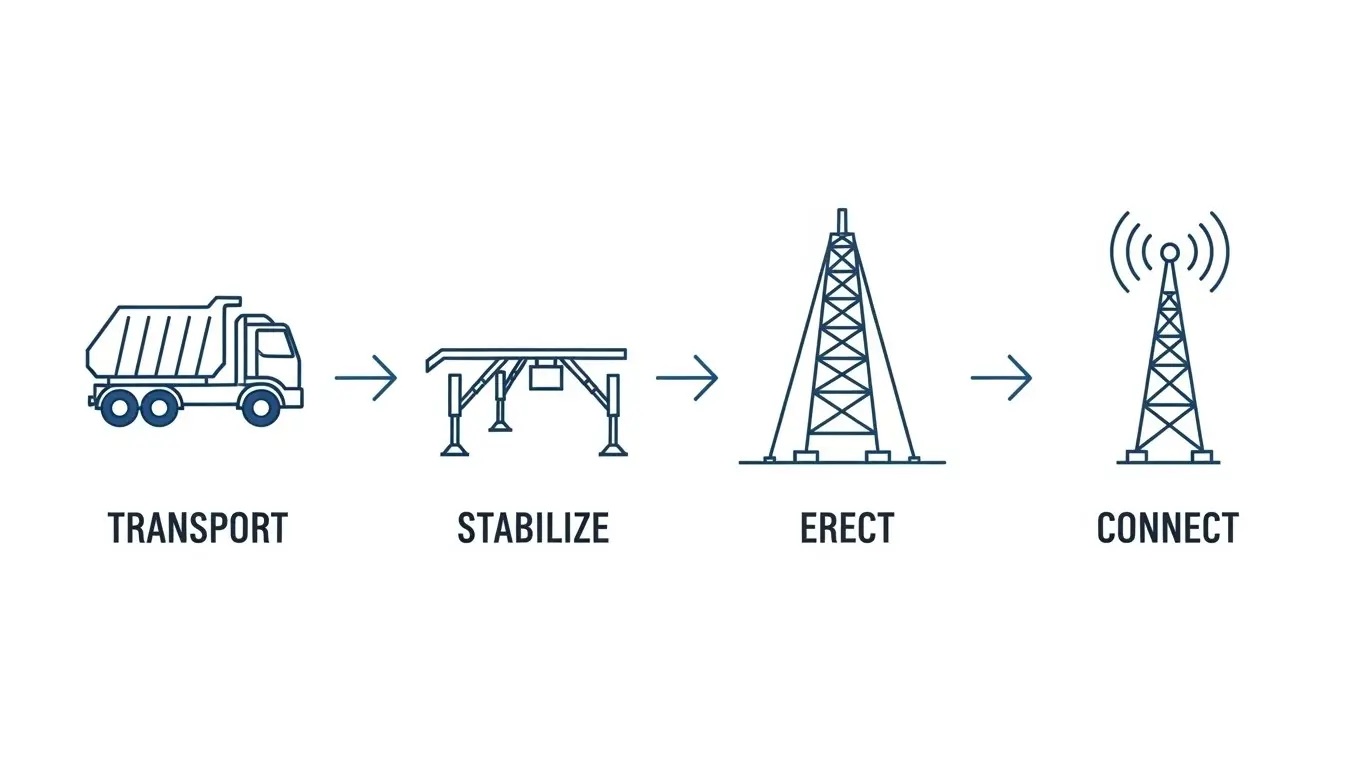

The Deployment Process

- Positioning: The unit is aligned so that solar panels face the sun (if applicable) and outriggers have solid ground contact.

- Stabilization: Outriggers are extended and locked. On soft soil, "dunnage" (wood or composite pads) is placed under the jacks to prevent sinking.

- Grounding: A copper grounding rod is driven into the earth and connected to the tower to dissipate lightning strikes.

- Erection: The mast is raised. For pneumatic systems, this is air pressure; for lattice towers, it is typically a hydraulic ram or electric winch system.

- Alignment: Technicians align the microwave backhaul link to the donor site.

Safety Standards and Certifications

Safety cannot be an afterthought when erecting tons of steel temporarily.

- ISO Certifications: Manufacturers should operate under ISO 9001 for quality management to ensure welds and hydraulics are tested.

- Emergency Stops: All hydraulic systems must have "dead man" switches and emergency stop buttons to prevent crushing injuries during retraction.

- Locking Mechanisms: Telescopic masts must have mechanical locking pins. You cannot rely on hydraulic pressure alone to hold a tower up for weeks; if a seal leaks, the tower comes down. Mechanical locks prevent this.

Conclusion

Rapid Deployment Units are not merely temporary fixes; they are a sophisticated category of telecommunications infrastructure that balances physics, logistics, and connectivity. Whether ensuring public safety during a natural disaster or enabling operations in a remote mine, the reliability of the solution depends on selecting the right architecture.

The trade-off is always between mobility and capacity. A lightweight trailer moves fast but carries less; a heavy-duty COL takes longer to deploy but survives a hurricane. Understanding these variables—wind load, payload, and power autonomy—is the key to a successful deployment.

For organizations requiring robust, engineering-certified mobile tower solutions, prioritizing TIA-compliant structures and hybrid power autonomy ensures that when the world goes offline, your operations stay connected.

Frequently Asked Questions (FAQ)

For a standard Cell on Wheels (COW), physical setup (stabilizing and raising the mast) can be completed in 30 to 60 minutes by a two-person crew. However, full network integration (aligning microwave dishes and configuring radios) may take an additional 1-2 hours depending on the complexity of the backhaul.

Most heavy-duty COWs are rated for 100 km/h to 120 km/h (approx. 60-75 mph) operational speeds. Survival speeds can reach 160 km/h (100 mph) when the unit is properly guyed and the mast is lowered to a safe position if the storm intensity increases. Always check the specific TIA-222 rating of the manufacturer.

It depends on the weight (GVWR) of the trailer. Many light-duty masts (< 3,500 kg) can be towed with a standard driver’s license. However, massive heavy-duty COWs often exceed weight limits and require a commercial driver's license (CDL) and a vehicle equipped with air brake controllers.

In most cases, solar is supplementary. A telecom load (radios + cooling) is constant and heavy. While solar panels on a trailer can extend battery life, a hybrid system (Solar + Batteries + Diesel Generator) is standard to ensure 99.99% uptime, especially during cloudy days or high-traffic nights.

A pneumatic mast uses air pressure to extend telescoping tubes; it is lighter, faster to deploy, and great for temporary surveillance or light comms. A lattice mast is built from steel grids; it is heavier and takes longer to erect but offers superior rigidity and payload capacity for heavy cellular equipment.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.