Steel Plate Buying Guide: How to Choose the Best Option

2025-04-21

Steel plates serve as versatile and foundational materials across industries, offering durability, strength, and adaptability. When purchasing steel plates for a specific application, understanding their key characteristics and options is essential to ensure optimal performance and cost-effectiveness. This guide introduces the critical aspects that influence steel plate selection, equipping buyers with the knowledge necessary to make informed decisions.

Selecting the right steel plates requires comprehending their diverse types, qualities, and intended uses. Steel plates come in varying grades, sizes, thicknesses, and finishes, each suited to distinct applications such as construction, engineering, manufacturing, or fabrication projects. Buyers must also consider the specific needs related to wear resistance, tensile strength, impact tolerance, or corrosion prevention based on their project scope.

Industry standards play a crucial role in steel plate selection. Manufacturers often classify steel plates by standards such as ASTM, ISO, or EN, which define mechanical properties and chemical compositions. Understanding these standards ensures the material meets safety and performance requirements while also complying with regulatory guidelines. Comparing these certifications can help narrow down your options effectively.

Buyers should also consider the environmental conditions under which the steel plates will operate, including exposure to moisture, extreme temperatures, or abrasive elements. For instance, a steel plate used in marine settings may require anti-corrosion treatments or alloying elements like nickel to enhance its resistance to salty water.

Key purchasing factors include the plate dimensions, surface treatment, manufacturing process, and cost. Examining supplier reliability, delivery timelines, and customer support ensures not only quick acquisition of the materials but also ongoing assistance for technical inquiries or project adjustments.

This guide sets the foundation for a holistic understanding of steel plate purchasing, ensuring every buyer is adequately equipped with critical knowledge before proceeding with a decision. It delves deeper into essential considerations for maximizing efficiency and utility in subsequent sections.

Understanding Different Types of Steel Plates

Steel plates come in various types, each tailored to meet specific applications and requirements. Buyers should understand the differences among them to ensure they select the most appropriate option for their needs. The following outlines the key types of steel plates and their characteristics.

Common Types of Steel Plates

- Carbon Steel Plates Carbon steel plates are composed primarily of carbon and iron, with minimal alloying elements. They are known for their strength, durability, and affordability. These plates are commonly used in construction, structural applications, and machinery manufacturing. The levels of carbon content—low, medium, or high—determine their suitability for particular tasks.

- Alloy Steel Plates Alloy steel plates incorporate additional elements, such as chromium, nickel, or manganese, to enhance their properties. These plates often exhibit improved wear resistance, toughness, and strength. Engineers frequently use them in demanding environments, including heavy machinery, pressure vessels, and industrial equipment.

- Stainless Steel Plates Stainless steel plates are highly resistant to corrosion and oxidation due to their chromium content. They are ideal for applications requiring durability in harsh environments, including food processing, chemical industries, and marine settings. Their aesthetic appeal also makes them popular in architectural designs.

- High-Strength Low-Alloy (HSLA) Plates HSLA plates provide excellent strength and lightweight characteristics. Designed to resist corrosion and withstand extreme pressures, they are widely used in structures like bridges, cranes, and ships.

- Tool Steel Plates Tool steel plates are developed for durability and hardness, making them ideal for cutting, pressing, or molding tools. These plates are commonly employed in manufacturing processes and high-temperature operations.

Specialty Steel Plates

- Abrasion-Resistant Plates Designed to endure heavy wear and tear, these plates are used in mining, construction, and other industries involving impact or friction.

- Marine-Grade Plates Specifically engineered for resistance to saltwater corrosion, marine-grade steel plates are a staple in shipbuilding and offshore structures.

Understanding the distinct properties of each type of steel plate helps in making informed purchasing decisions based on the intended application and operating environment.

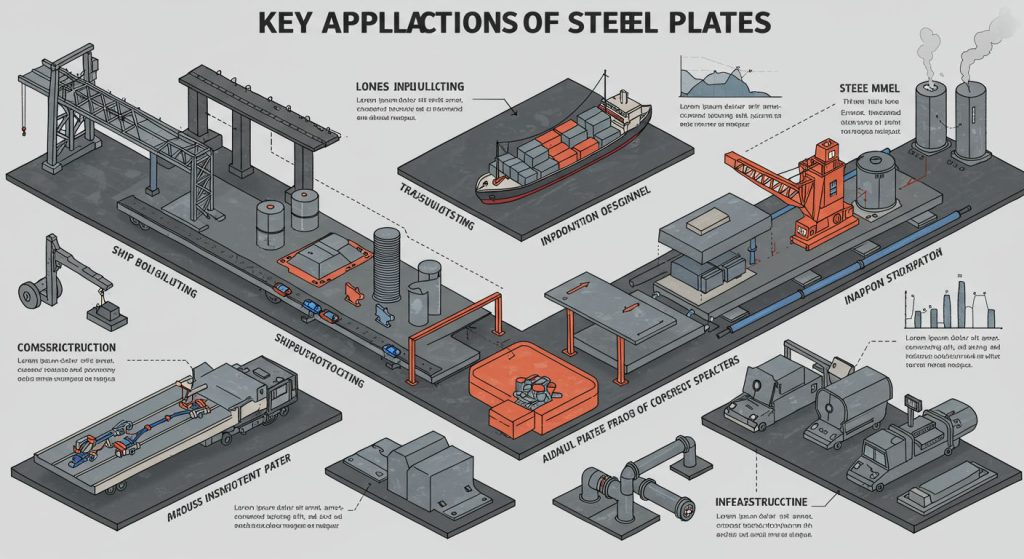

Key Applications of Steel Plates Across Industries

Steel plates serve as a vital component in numerous industries due to their robustness, durability, and versatility. Each application leverages specific types of steel plates based on the required mechanical and chemical properties.

1. Construction and Infrastructure

Steel plates play a critical role in the construction sector. They are commonly used in building foundations, bridges, and load-bearing structures. Their excellent strength-to-weight ratio ensures stability in high-rise buildings and industrial facilities. Reinforced steel plates are essential in earthquake-resistant designs and support systems like beams and girders.

2. Automotive Industry

In the automotive sector, steel plates contribute to the production of vehicle frames, chassis, and body components. High-strength, low-alloy (HSLA) steel plates are frequently used, offering durability while maintaining reduced vehicle weight for fuel efficiency and safety. They also support advanced crash management systems in vehicles.

3. Shipbuilding

Marine environments demand materials with resistance to corrosion and extreme conditions. Steel plates, particularly marine-grade varieties, are utilized in the construction of ship hulls, cargo tanks, and bulkheads. Their ability to endure high tensile stresses and rough sea conditions makes them indispensable in shipbuilding.

4. Oil and Gas Industry

Steel plates are heavily used in the fabrication of storage tanks, pipelines, and pressure vessels within the oil and gas sector. These plates are designed to withstand high pressures, corrosive substances, and extreme temperatures. Boiler-grade plates are a common choice for maintaining safety in such demanding environments.

5. Defense and Military

The defense industry relies on steel plates for the manufacturing of armored vehicles, protective barriers, and naval vessels. Advanced steel alloys with ballistic properties are utilized to enhance protection and ensure resilience under combat scenarios.

6. Heavy Machinery and Equipment

Steel plates are essential in the production of heavy equipment such as cranes, bulldozers, and mining machinery. Their durability ensures the ability to withstand significant mechanical stress, aiding in performance and longevity.

7. Energy Sector

In power plants, whether thermal, nuclear, or renewable, steel plates are integral to turbines, boilers, and structural components. Wind turbines also employ specialized steel plates in their construction to ensure strength and operational efficiency.

8. Transportation and Railway

Steel plates are a standard component in manufacturing railway tracks, railcars, and freight wagons. Their impact resistance and durability support the safe transport of passengers and goods over long distances.

The vast adaptability of steel plates continues to make them a cornerstone material across these industries. Each application is a testament to the critical role that steel plates play in driving industrial progress and innovation.

Factors to Consider When Choosing a Steel Plate

Selecting the right steel plate requires a thorough evaluation of several critical factors to ensure suitability for intended applications. Each factor impacts the plate's performance, durability, and cost-effectiveness, demanding careful analysis.

1. Material Grade and Composition

Steel plates are available in various grades, each designed for specific applications. Consider whether carbon steel, alloy steel, or stainless steel is required, as the composition affects properties such as strength, corrosion resistance, and weldability. High-strength low-alloy steel grades might be necessary for structural applications, while stainless steel grades are optimal for environments requiring corrosion resistance.

2. Thickness and Size

The thickness of the steel plate plays a critical role in determining its load-bearing capabilities and suitability for particular uses. Ensure that the selected thickness aligns with the design specifications and safety requirements. Size and dimensions also matter when considering compatibility with machinery, transportation, and fabrication processes.

3. Mechanical Properties

Evaluate the steel plate’s tensile strength, yield strength, hardness, and impact resistance. These properties determine how the plate will perform under stress and pressure. For applications subject to extreme forces or harsh conditions, steel grades with higher mechanical integrity are preferred.

4. Application Requirements

Different industries require steel plates for diverse purposes, such as construction, manufacturing, or shipbuilding. Consider whether the plate will be exposed to factors such as high temperatures, moisture, chemicals, or mechanical wear. Customized solutions should align with the specific functional requirements of the project.

5. Surface Finish

Surface finish affects aesthetics, performative capabilities, and protective qualities. Some applications demand mill finish for cost-efficiency, while others may require treated finishes like galvanized or painted surfaces for enhanced durability.

6. Standards and Certifications

Verify compliance with relevant industry standards and certifications such as ASTM, ASME, or ISO. Ensuring adherence to these guidelines validates the steel plate's quality and suitability for its intended use.

7. Cost and Availability

Budget constraints often influence material choices. Compare options based on price and lead times while considering long-term trade-offs like maintenance costs and lifespan. Availability should also be checked to avoid supply chain delays.

By evaluating these aspects systematically, buyers can select steel plates that meet their specifications reliably and economically.

Analyzing Steel Plate Thickness: What You Need to Know

When selecting steel plate thickness, understanding the specific requirements of the application is essential. Steel plate thickness not only impacts the plate's structural strength but also affects weight, cost, and workability. Therefore, several factors warrant consideration to make an informed choice.

Factors to Consider When Selecting Thickness

- Load-Bearing Capacity The intended load the steel plate must withstand largely determines its required thickness. Applications involving heavy loads, such as bridges or industrial machinery, often demand thicker plates to ensure durability and prevent deformation.

- Function and Application Different industries and projects require varying plate thicknesses. Thin plates, typically under ¼ inch, are used in decorative or lightweight applications, such as furniture or automotive parts. Conversely, thicker plates, often exceeding 1 inch, are used in construction, shipbuilding, or fabrication of pressure vessels.

- Material Efficiency Over-specifying plate thickness can lead to unnecessary material costs and increased weight, impacting transportation and installation. Selecting a thickness based on engineering calculations can optimize material usage without compromising safety.

- Regulatory Standards Compliance with ASTM, EN, or other standards is critical for industrial steel plates. These regulations often specify a minimum thickness based on the plate's intended use, helping guide buyers toward appropriate specifications.

Tools and Techniques for Thickness Analysis

Professionals often use tools such as calipers, ultrasonic thickness gauges, or non-destructive testing (NDT) methods to verify thickness accuracy. These techniques ensure the plate meets design criteria and safety requirements.

Steel plate thickness directly influences its ability to meet application-specific demands. Buyers should assess all relevant factors, ensuring the plate can perform effectively under expected conditions.

Exploring Steel Plate Grades and Their Importance

Steel plate grades play a critical role in determining the performance, durability, and application of steel in various industrial and commercial projects. Each grade is distinguished by its composition, strength, and intended usage, which makes selecting the right grade essential for achieving project-specific goals. Understanding the key factors associated with steel plate grades helps buyers make more informed decisions.

Steel plates are primarily classified based on their chemical composition and mechanical properties. Among the most common grades are A36, A572, A516, and AR (abrasion-resistant) grades. The A36 steel plate is widely recognized for its general structural applications, offering excellent weldability and machinability. It is often chosen for projects requiring moderate strength, such as bridges, buildings, and structural components. On the other hand, A572 is preferred for high-strength applications due to its superior tensile strength and resistance to forces.

For projects involving pressure vessels, boilers, and tanks, A516 is one of the most desirable grades. This grade is specifically designed to withstand extreme pressure and high temperatures, making it a key choice for industries like oil and gas. Abrasion-resistant (AR) grades are tailored for equipment and structures subject to excessive wear and tear, such as mining and construction machinery. These plates boast exceptional hardness and durability.

When evaluating steel plate grades, other considerations such as impact resistance, corrosion resistance, and heat tolerance are crucial. Various industries, including shipbuilding, manufacturing, and infrastructure development, rely on the unique properties of steel grades to meet exacting requirements. Specifications such as yield strength, elongation, and toughness contribute significantly to determining the suitability of a steel plate for a given application.

By ensuring compatibility between project demands and steel grade characteristics, buyers can achieve optimal performance, safety, and cost-efficiency. Proper understanding of steel plate grades is indispensable for optimizing results in engineering, industrial, and commercial contexts.

Decoding Steel Plate Surface Finishes and Coatings

When purchasing steel plates, understanding surface finishes and coatings is crucial for selecting the appropriate material for specific applications. Surface finishes and coatings are engineered to enhance the physical, mechanical, and chemical properties of steel, catering to performance requirements and environmental conditions.

Types of Steel Plate Surface Finishes

Steel plates are manufactured with a variety of surface finishes, each serving distinct purposes:

- Hot Rolled Finish: Hot rolled steel plates have a rough surface texture resulting from high-temperature processing. They are cost-effective and widely used in structural applications where aesthetics are less critical.

- Cold Rolled Finish: Cold rolled plates undergo further processing to achieve a smooth and glossy finish by rolling at room temperature. Such finishes are common in applications requiring precision and enhanced surface quality.

- Matte Finish: Matte finishes reduce glare and create non-reflective surfaces for industries like construction and automotive.

- Polished Finish: Polished finishes involve buffing or grinding to achieve a smooth, reflective appearance, ideal for decorative purposes and applications requiring corrosion resistance.

Common Steel Plate Coatings

Coatings provide additional protection against environmental factors such as moisture, chemicals, and physical wear:

- Galvanized Coating: Zinc is applied to steel plates through galvanization to resist corrosion, especially in outdoor environments.

- Paint Coating: Paints enhance aesthetics while providing a protective barrier against oxidation and rust. Paint types vary based on application needs, including epoxy or polyurethane options for industrial uses.

- Powder Coating: Powder coating offers durability and abrasion resistance, ideal for heavy-duty applications requiring robust protection.

- Specialized Coatings: Advanced solutions like anti-microbial, fire-resistant, or chemical-resistant coatings are tailored to meet unique industry demands.

Steel plate finishes and coatings are integral in determining their functionality, durability, and suitability for individual projects. Therefore, careful consideration of these elements ensures optimal performance and longevity in diverse operational contexts.

Budgeting for Steel Plates: Cost vs Quality

When considering steel plates, balancing cost with quality is critical to achieving both durability and financial prudence. Steel plates are available in various grades, thicknesses, and finishes, all of which significantly impact their pricing and overall performance. Buyers must weigh these factors carefully based on the application and intended usage.

Factors Influencing Cost

- Material Grade: High-strength or alloy steel plates are generally more expensive than standard carbon steel options due to their specialized properties.

- Thickness: Thicker plates usually require more raw material, leading to increased costs. However, they may provide enhanced durability for heavy-duty applications.

- Dimensions: Larger plates incur higher costs as they demand more surface area and resources during fabrication.

- Processing Requirements: Additional treatments, such as heat treatment or surface coating, can raise expenses but improve wear resistance, corrosion protection, or machinability.

- Supplier and Location: Regional differences in labor costs and access to raw materials can influence pricing significantly.

Recognizing Quality over Short-Term Savings

Prioritizing cost at the expense of quality can result in compromised performance or premature wear, leading to long-term financial losses. In industrial applications, subpar plates may fail under stress, necessitating costly repairs or replacements. Additionally, higher-grade plates often deliver enhanced strength, resistance to fatigue, and longevity, justifying the upfront expense in critical-use scenarios.

Practical Budgeting Tips

- Define Application Needs: Clearly identify the required mechanical properties, such as tensile strength or corrosion resistance, to prevent overspending on unnecessary features.

- Compare Suppliers: Solicit multiple quotes and compare warranties to identify the best value for money without sacrificing quality.

- Plan for Long-Term Savings: Evaluate the lifecycle costs of the steel plate by factoring in maintenance, repair, and replacement needs.

Thoughtful budgeting ensures an optimal balance between price and performance, empowering buyers to invest with confidence.

Where to Buy Steel Plates: Trusted Suppliers and Vendors

When searching for steel plates, selecting a reputable supplier or vendor ensures product quality, consistency, and timely delivery. Several established channels offer robust options for procuring steel plates based on specific project requirements.

1. Specialized Steel Distributors

Steel distributors often provide a wide selection of grades, sizes, and finishes. These suppliers are experts in sourcing and often cater to a vast range of industries such as construction, manufacturing, and marine applications. Customers benefit from comprehensive product catalogs, technical expertise, and customization services. Some distributors focus on providing bulk orders, making them ideal for large projects.

2. Local Steel Service Centers

Local steel service centers combine proximity and convenience, offering access to steel plates in standard sizes or customized dimensions. These centers often provide prep services, including cutting, shearing, or welding, to meet exact client specifications. Businesses operating under tight deadlines may find local vendors particularly advantageous for reduced lead times and quick delivery.

3. Online Metal Suppliers

Online platforms now provide a convenient option for purchasing steel plates. Many websites allow users to compare prices, browse material specifications, and place orders directly. This channel is especially beneficial for smaller purchases or unique grades that may not be readily available locally. Reputable online vendors often provide certification documents, ensuring compliance with industry standards.

4. Directly from Manufacturers

Purchasing steel plates directly from manufacturers can offer cost advantages and advanced customization options. This approach suits businesses requiring large, tailored quantities for industrial or commercial use. Manufacturers are also more likely to provide technical support and documentation, including mill test reports.

5. Salvage Yards or Secondary Suppliers

For cost-effective alternatives, salvage yards and secondary suppliers may carry surplus or recycled steel plates. While these options may not always guarantee consistent quality, they can be suitable for non-structural or low-budget projects. Buyers should inspect materials thoroughly to ensure they meet application requirements.

Choosing the right supplier depends on factors such as the project's scope, required material grade, and delivery timelines. Verifying certifications, reading reviews, and requesting samples are critical steps in ensuring a reliable purchase.

Tips for Inspecting Steel Plates Before Purchase

When purchasing steel plates, conducting a thorough inspection ensures the material meets the desired specifications and quality standards. Proper evaluation minimizes risks associated with defects or substandard materials. Below are several essential tips for inspecting steel plates before finalizing a purchase.

1. Check Physical Dimensions

Measure the steel plate’s thickness, width, and length to confirm the dimensions align with project requirements. Use calibrated tools such as micrometers, calipers, or tape measures for accurate readings. Verify that dimensional tolerances comply with industry standards or specific needs.

2. Assess Surface Quality

Examine the surface for any visible imperfections such as cracks, scratches, dents, or corrosion. Steel plates with uniform finishes and free of defects are crucial for performance and aesthetics, especially in structural and industrial applications. Pay close attention to welding seams or edges, as these areas are prone to irregularities.

3. Verify Material Grade and Certification

Confirm the steel plate’s material grade against the project’s specifications and ensure it adheres to standard classifications (e.g., ASTM grades). Request mill certification or documentation that verifies chemical composition, mechanical properties, and compliance with required standards.

4. Review Flatness and Straightness

Inspect the flatness of the steel plate to prevent distortions in assembly or installation. Place a straightedge tool across the surface to check for inconsistencies or bends. Even minor unevenness can impact the integrity of the structure or final product.

5. Evaluate Weight and Density

Calculate the steel plate’s weight based on its dimensions and density. Comparing actual weight to expected values ensures no material discrepancies. Abnormal weight variances may indicate issues with composition or manufacturing.

6. Investigate Quality Signs

Confirm no signs of overheating, scaling, or defect during production. Material defects can result from improper rolling or cooling processes. Additionally, inspect for uniform grain patterns to ensure structural integrity, especially for load-bearing applications.

7. Perform a Hardness Test (If Applicable)

For applications requiring high tensile strength, perform hardness testing to confirm durability. Request pre-testing from suppliers or perform on-site tests with portable hardness measurement tools.

8. Coordinate with Suppliers

Collaborate closely with vendors or suppliers to ensure steel plates are sourced and handled responsibly. Request clarity on manufacturing conditions, transport, and storage facilities for better material reliability. Suppliers often provide insights into handling instructions and best practices.

9. Schedule Third-Party Inspection

For projects requiring high precision, consider engaging third-party inspectors to evaluate steel plates. Independent inspections detect minute inconsistencies or quality deviations that may go unnoticed otherwise.

By thoroughly inspecting steel plates prior to purchase, buyers can ensure optimal performance and alignment with intended applications.

How to Maintain and Store Steel Plates Effectively

Proper maintenance and storage of steel plates are crucial to ensuring their longevity, preserving their structural integrity, and safeguarding their usability for future applications. Implementing effective practices not only prevents corrosion and damage but also reduces wastage and cost. Here are actionable steps and considerations to store and maintain steel plates effectively:

Maintenance Practices

- Regular Cleaning Steel plates should be cleaned periodically to remove dirt, oil, grease, and other contaminants. Using mild detergents and non-abrasive cleaners helps maintain the surface quality without causing scratches or abrasion.

- Rust Prevention Steel is prone to corrosion if exposed to moisture and oxygen for prolonged periods. Applying protective coatings, such as oil, wax, or anti-corrosion sprays, can shield the steel plates from rust. Galvanized steel plates may already come with a protective layer, but they still require maintenance in high-humidity environments.

- Inspection Conducting routine inspections helps identify signs of wear, cracks, or corrosion early. Addressing such issues promptly ensures structural integrity and prevents further damage.

- Handling with Care When moving or handling steel plates, workers should use appropriate tools, such as forklifts or hoists, to avoid scratches, dents, or bending. Dropping plates or dragging them on abrasive surfaces can compromise their quality.

Storage Best Practices

- Controlled Environment Steel plates should be stored in dry, temperature-controlled spaces that minimize exposure to moisture and extreme temperatures. Indoor storage areas help prevent rust and weather-related deterioration.

- Elevation Storing steel plates off the ground, using pallets or racks, reduces contact with water and debris, safeguarding them from dirt accumulation and moisture.

- Ventilation Proper air circulation in storage areas prevents condensation from forming on the steel plates. Ventilation is especially critical in humid regions.

- Organization Steel plates should be stored horizontally and stacked according to their size and weight. Avoid stacking them too high to prevent damage from excess pressure. Use separators between layers to reduce friction and scratches.

- Labeling and Identification Organizing steel plates with clear labels indicating grade, thickness, and dimensions ensures easy access and reduces handling errors. Proper cataloging also helps during inventory management.

Long-Term Storage Considerations

For extended storage periods, steel plates should be regularly inspected and re-coated, if necessary. Covering them with tarps or plastic sheeting can prevent exposure to airborne debris and moisture while still allowing ventilation. Following these measures reduces maintenance costs and ensures the steel plates remain ready for use when needed.

The Future of Steel Plate Technology: Trends to Watch

As industries continuously evolve, advancements in steel plate technology are reshaping possibilities. From manufacturing to construction, the future of steel plate innovation is positioned to deliver breakthroughs that enhance performance, durability, and cost-efficiency. Several emerging trends are worth noting for buyers and industry professionals keeping an eye on the future.

Integration of Advanced Metallurgy

Steel manufacturing is trending toward utilizing advanced metallurgy techniques, such as low-alloy steels and high-strength steels, to improve material toughness and longevity. These innovations are driven by the demand for lighter yet stronger plates in automotive and aerospace industries, contributing to weight reduction without compromising structural reliability.

Enhanced Sustainability Approaches

A stronger push for environmentally friendly methods is leading to the use of energy-efficient production processes and recycling strategies. Steel manufacturers are investing in technologies that reduce carbon emissions significantly while leveraging scrap materials. Buyers seeking steel plates with eco-certifications will likely find more sustainable options in the future.

Smart Steel Plates with Embedded Sensors

Smart technology is extending beyond electronics into materials science. Steel plates integrated with embedded sensors provide real-time data on stress, temperature, and corrosion levels. These plates enhance safety and operational insights for industries like infrastructure and heavy machinery. This technological leap is expected to redefine structural monitoring and predictive maintenance.

Customization Powered by Automation and AI

Artificial intelligence and automation are reshaping the steel plate fabrication process. Through advanced modeling systems, manufacturers can create highly tailored solutions, such as plates with unique thickness requirements, specific tolerances, or composite layering. These innovations cater to industries demanding precision, such as renewable energy projects and defense.

Development of Nanotechnology in Steel

Nanotechnology is increasingly infiltrating steel plate production to revolutionize properties like strength, ductility, and resistance to environmental factors. The use of nanoscale additives allows steel plates to deliver enhanced performance in extreme conditions, such as offshore drilling and high-pressure installations.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.