Top 10 Electric Transmission Tower Manufacturers: Guide

2025-08-22

Use of Electric Transmission Towers: A Global Guide to Quality & Innovation

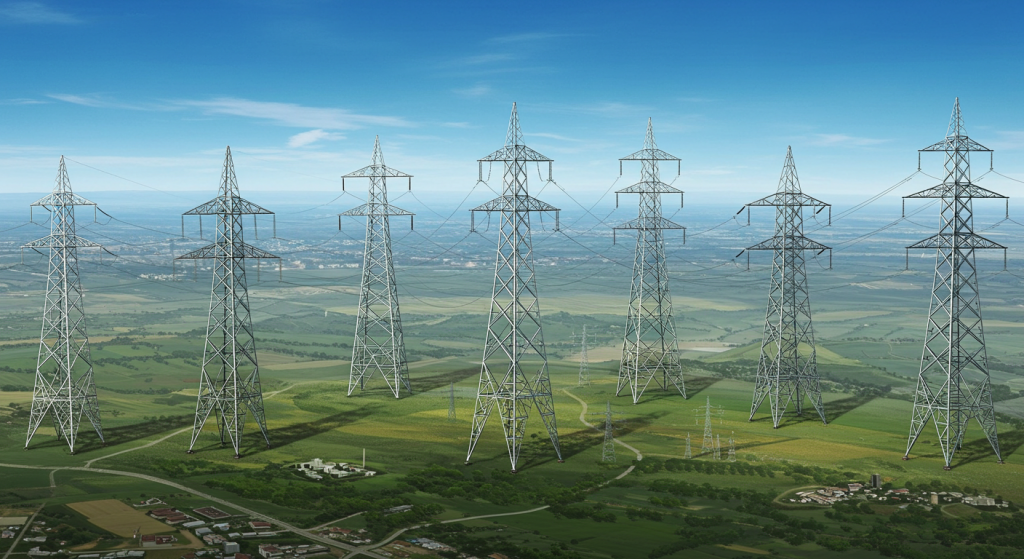

The silent giants that move our modern world are the electric transmission towers of our world. These steel wonders light up houses and power industries as these high-voltage wires transfer electricity across cities, countries, and borders. In case you want to know the best electric transmission tower manufacturing companies in the world, you are in the right place.

XY Tower

XY Tower is a top electric transmission tower maker in China. The company is known for high-voltage lattice towers and galvanized steel tower solutions and offers:

- Galvanized towers built on hot-dipped steel

- CNC tower manufacture

- Custom tower design services

- ISO/IEC certified plant, ISO/IEC fabrication plant

Distributed around the world, their towers are standard in HV and EHV applications and have been designed to critical anti-corrosion and load-bearing specifications. XY Tower is a leading company choice by power utilities through its fast distribution, large-scale manufacturing, and OEM officiating.

Innovation in Technology That Makes These Manufacturers Unique

Leading producers of electric transmission towers are distinguished by their adherence to the ideas of novelty and new engineering standards. These companies use the most advanced software, like PLS-CADD, which is able to maximize load-carrying capacity and ensure that every structure is able to withstand adverse environmental conditions and heavy electrical loads.

- The utilization of robotic welding is well spread to ensure that there is precision in welding braces and joints assembly, with fewer chances of human error and high consistency between any production batches. This prolongs the lifetime and combats corrosion, hence most manufacturers use hot-dip galvanization, taking into account that the steel may be subjected to coastal or other humid weather.

- The ability to fabricate accurately is even extended through CNC and laser cut technologies to reach perfect alignment of bolt-holes and leg fitting factors of structural integrity at the time of installing and operating them. More complex tower leg and cross-arm design methods mean not only a more aesthetically uniform appearance, but also stronger structures.

- Moreover, these manufacturers do not ignore wind load calculations and seismic zoning, as they take them into consideration to tailor tower geometry to suit a region. This ensures high-wind and earthquake-prone areas.

- All the innovations comply with the international standards, i.e., IEC, ANSI, and ISO, and are reliable worldwide, safe, and of high quality. The above technical improvements mean that the latest, durable power transmission infrastructure is favored by the best manufacturers.

Why Galvanized Steel: The Gold Standard?

Galvanized steel has won the title of industry gold standard in the electric transmission tower world, and it is clear why this is the case. The hot-dip galvanization is used by all the high-level transmission tower manufacturers in order to increase the durability and longevity of their structures made of steel.

- The steel parts are submerged in a bath containing molten zinc in a process that produces a hard, corrosion-resistant layer and a metallurgical bond between the mass of zinc and the metal being coated with steel. The result? Very durable, resistant to corrosion-ability to withstand the toughest environmental elements, such as coastal salty air, industrial pollutants, or heat in a dry area.

- Due to a thick zinc coating by ISO 1461 standards, galvanized towers do not require much maintenance in the course of their service life. Not only does this save the utility company’s time and resources, but makes the total efficiency of the transmission network increase within this process.

- Above all, galvanized steel towers have a long service life, as in most cases, more than 30 years. This renders them economical and sustainable when it comes to large-scale power infrastructure.

- Regardless of location (desert or the city grid), galvanized steel has been proven robust, reliable, and capable of withstanding the test of time, and offers the best solution, hence the reason why it is used by the best 10 electric transmission tower manufacturers around the world.

OEM & Custom Tower Design Services

The concept of custom tower design services has also become a necessity in ensuring that successful power transmission projects occur in the context of complex grid environments. Leading manufacturers of electric transmission towers, such as XY Tower, the top 10 electric transmission tower manufacturers, provide all-around OEM and customized engineering services that exactly fit the project demands.

- These tower tailor designs are also optimized to compare to site-specific parameters such as ground, wind load, seismic activity, and environmental factors. Through the use of GIS mapping, wind speed analysis, and soil tests on resistivity, such manufacturers guarantee that every tower is strong and very effective.

- Depending on whether 33kV distribution lines are required or 765kV ultra-high-voltage transmission, OEM providers can limit or extend the design depending on the desired voltage, conductor structure, and length of span. Towers are designed flexibly- tailored leg extensions, bracing configurations, and cross-arm adaptations can easily adapt to local standards and utility needs.

- Being the brightest representative in this sphere, XY Tower Company has been dealing with the development of project-oriented tower prototypes, provision of full-cycle project-related design, to installation services compliant with IEC, ANSI, and GB standards. What this does is it creates a better performance of the load-bearing, simple erection, and long-term stability.

Selecting the Proper Manufacturer

The following are important considerations when you are choosing the best 10 electric transmission tower manufacturing companies:

- International Projects Experience

Select a manufacturer that has a good history of undertaking successful transmission ventures around the world.

- Compliance with the Standards

Make sure that they become internationally acceptable with regard to quality and safety and are to last, bearing a standard like ISO, IEC, and ANSI.

- Advanced Manufacturing Capability

Seek plants that have CNC fabrication in place and robotic welding so you can rely on accuracy and repeatability.

- Global Delivery & Logistics Support

Choose a manufacturer that can internationalize delivery without much hassle and bear any logistics required to ensure delivery.

- Affordability & Bulk Shipping & Handling

Turn to a supplier that is competitive in their prices and preferably can issue large quantity orders without sacrificing quality.

Conclusion

Electricity Transmission Towers are not simply steel towers, which are a lifeline of our power grids. Grid resilience and the success of any project demand the ability to select a manufacturer with a quality reputation, innovation, and compliance throughout the world. XY Tower is one of the best, top 10 electric transmission tower manufacturers, providing a complete, one-stop solution. They build the world, tower by tower, with high-voltage know-how, custom engineering, and turnkey service.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.