Professional Tower Installation Services for Telecom Operators

2025-10-25

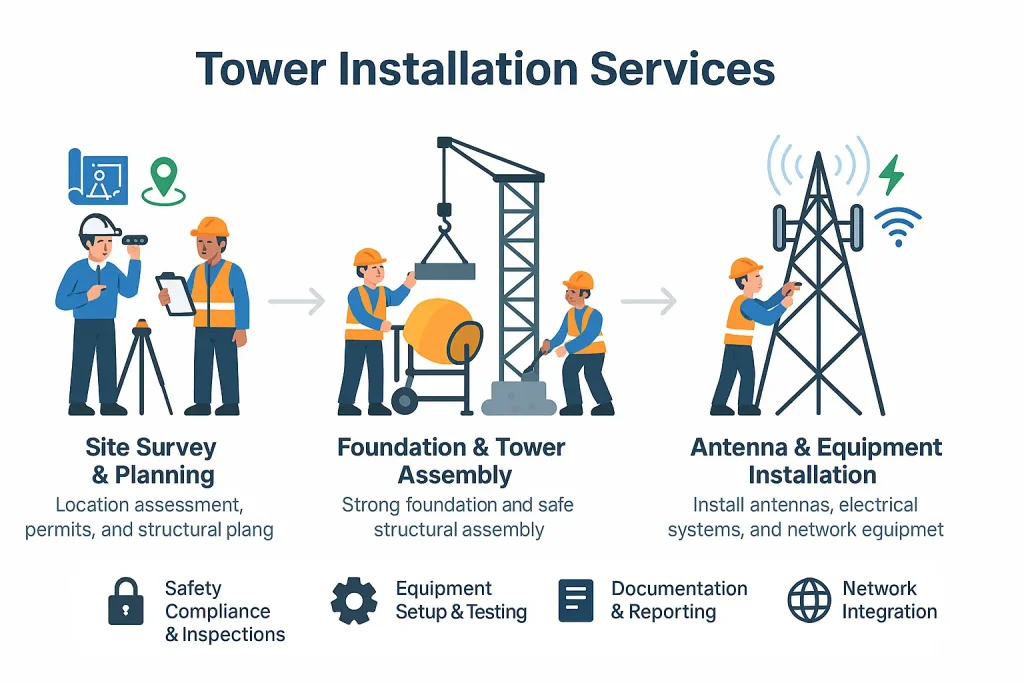

Professional tower installation services are the critical foundation upon which reliable telecommunications networks are built. This complex process involves the expert construction and erection of Telecommunications Tower structures, demanding meticulous planning, specialized engineering, rigorous safety protocols, and highly skilled execution. For telecom operators expanding their reach or upgrading their infrastructure, partnering with an experienced installation provider is paramount.

This definitive guide provides an expert overview of the entire installation lifecycle. It covers pre-construction planning, foundation work, erection methods, safety management, and quality assurance. It explains what defines a truly professional service capable of delivering robust and enduring tower assets.

What Defines Professional Tower Installation Services?

Professional tower installation services are defined by a comprehensive, safety-focused approach encompassing expert engineering, meticulous project management, certified crews, adherence to rigorous standards, and robust quality assurance from site preparation through final inspection.

These services go far beyond simple construction. They represent a specialized discipline requiring deep knowledge of structural engineering, geotechnical factors, complex rigging techniques, and uncompromising safety practices. A truly professional provider manages every aspect of the physical build. They ensure the final structure is not only compliant with all design specifications and regulations but also built to withstand environmental stresses for decades. This level of professionalism is essential for protecting significant infrastructure investments and ensuring network reliability.

How Crucial is Pre-Installation Planning?

Pre-installation planning is absolutely crucial. It involves detailed site assessments, constructability reviews, logistical coordination for materials and equipment, development of site-specific safety plans, and precise scheduling. Thorough planning minimizes delays, prevents costly errors, and ensures a safe, efficient execution.

Effective planning is the bedrock of a successful installation. Before any ground is broken, experts review engineering designs against actual site conditions. They identify potential access issues for heavy equipment like cranes. Material delivery timelines are coordinated. A detailed Job Safety Analysis (JSA) identifies potential hazards specific to the site and outlines mitigation strategies. Rigging plans are developed to ensure safe lifting operations. This meticulous preparation phase streamlines the entire construction process. It reduces the likelihood of unexpected problems that could derail the project timeline or budget. The benefits of thorough project planning in complex construction are well-documented.

What Expertise is Required for Structural Engineering Support?

Structural engineering support requires expertise in telecommunications structures, foundation design based on geotechnical data, load calculations (including wind and ice), and compliance with relevant TIA/EIA standards. Engineers ensure the tower design is sound and appropriate for the specific site conditions.

While the installation company may not design the tower itself, they must have engineering expertise on staff or readily available. This expertise is needed to interpret complex structural drawings, validate foundation designs based on soil reports, and potentially design temporary structures or rigging aids. Engineers also play a crucial role in quality control, verifying that construction adheres to design tolerances. They may be involved in designing structural modifications if unforeseen site conditions arise. This engineering oversight ensures the tower's long-term structural integrity. As a leading telecom infrastructure provider, engineering excellence is fundamental.

Why Are Certified Crews and Rigorous Safety Non-Negotiable?

Certified crews and rigorous safety protocols are non-negotiable because tower work is inherently high-risk. Certifications (like NATE Climber/Rescuer) validate essential skills. Strict adherence to safety standards (including 100% fall protection) prevents accidents, protects lives, and mitigates liability.

There is zero margin for error when working at height with heavy steel components. Professional installation companies invest heavily in safety.

- Training and Certification: Crews must undergo extensive, documented training covering climbing techniques, fall protection systems, rescue procedures, RF safety, and equipment operation. Certifications must be current.

- Safety Culture: Safety must be ingrained in the company culture, from top management down to every crew member, with clear authority to stop work if conditions are unsafe.

- Equipment: All climbing gear, rigging equipment, and safety devices must be regularly inspected, maintained, and meet or exceed industry standards.

- Protocols: Strict adherence to established procedures for climbing, rigging, lifting, and site management is mandatory. Choosing a provider with an impeccable, verifiable safety record is paramount. Look for metrics like low EMR ratings and comprehensive safety programs. Worker safety in high-risk industries is a major focus globally.

How Does Project Management Ensure Success?

Effective project management ensures success by coordinating all aspects of the installation, managing timelines and budgets, overseeing subcontractors, communicating with stakeholders, and proactively resolving issues. Experienced project managers are crucial for keeping complex installations on track.

A dedicated project manager (PM) serves as the central point of contact and control. They develop the detailed construction schedule, coordinate equipment mobilization, manage material deliveries, and oversee the daily activities of the installation crew and any subcontractors (like concrete or electrical teams). The PM tracks progress against milestones, manages the budget, ensures compliance with permits, and communicates regularly with the client (the telecom operator). Their ability to anticipate challenges and implement solutions quickly is vital for delivering the project on time and within budget. Strong project management is a hallmark of top-tier telecom tower services.

What Quality Assurance Measures Are Essential?

Essential quality assurance measures include material certifications, adherence to engineered drawings and tolerances, regular inspections during construction (welds, bolts, alignment), concrete strength testing, final plumbness checks, and comprehensive documentation.

Quality assurance (QA) is an ongoing process throughout the installation. It begins with verifying that all materials delivered to the site meet the specified standards. During construction, QA technicians perform regular checks:

- Foundation: Verifying rebar placement, concrete mix design, and final dimensions. Conducting concrete strength tests after curing.

- Steel Erection: Inspecting bolted connections for proper torque, verifying weld quality (if applicable), checking member alignment.

- Plumbness: Using transits or laser alignment tools to ensure the tower is erected perfectly vertically within specified tolerances.

- Documentation: Maintaining detailed records of all inspections, tests, and materials used, creating a final turnover package for the client. This rigorous QA process ensures the finished tower meets all engineering requirements for safety and longevity.

What is the Step-by-Step Tower Installation Process?

The tower installation service follows a logical, step-by-step process, moving from groundwork to the final placement of the uppermost sections. Each phase requires careful execution by skilled professionals adhering to strict safety and quality standards. This methodical approach ensures the structure is built correctly from the foundation up.

How is the Site Prepared for Construction?

Site preparation involves clearing vegetation, grading the land to create a level work area, establishing stable access routes for heavy equipment, excavating for the foundation, and confirming the precise location and orientation of the tower base using survey instruments.

Proper preparation is vital for a smooth construction phase. The work area must be large enough to accommodate crane setup (if used), material staging, and safe movement of personnel. Access roads must be capable of supporting heavy trucks delivering concrete and steel sections. Erosion control measures may be implemented. Underground utilities are located and marked before any digging begins. Surveyors precisely stake out the exact center point and orientation of the tower foundation according to the engineered plans. This ensures the tower is built in the correct location and aimed in the right direction.

What are the Methods for Foundation Construction?

Foundation construction involves excavating to the specified depth, assembling and placing a cage of reinforcing steel (rebar), setting anchor bolts precisely, pouring high-strength concrete, and allowing it to cure properly. The specific design depends on tower type and soil conditions.

The foundation is the critical interface between the tower and the ground. Geotechnical reports dictate the required depth and design.

- Excavation: Soil is removed to the specified dimensions.

- Rebar Cage: A complex cage of reinforcing steel bars is assembled and placed within the excavation. This provides tensile strength to the concrete.

- Anchor Bolt Assembly: A template is used to hold the large anchor bolts in their exact positions while the concrete is poured. These bolts will secure the base of the tower. Precision here is paramount.

- Concrete Pour: High-strength concrete is poured into the formwork, ensuring no voids are present through proper vibration.

- Curing: The concrete must cure for a specified period (often 7 to 28 days) to reach its required compressive strength before the tower can be erected. Strength tests are performed on concrete samples. Foundation failure is catastrophic, making this stage crucial.

How is the Tower Structure Assembled and Erected?

Tower erection involves assembling sections of the tower on the ground (if feasible) and then lifting them into place using cranes, gin poles, or helicopters. Crews working at height bolt the sections together, ensuring proper alignment and torque on all connections.

The method depends on the tower type and site logistics.

- Monopoles: Typically arrive in large, slip-fit sections. A crane lifts each section, and it slides over the section below it.

- Lattice Towers: Arrive as individual steel members or pre-assembled panels. Sections are assembled on the ground, then lifted by crane or gin pole. Crews bolt the sections together in the air.

- Guyed Towers: Similar to lattice towers, but also involve the careful installation and tensioning of multiple guy wires anchored to the ground. This phase requires highly skilled climbers and riggers working in close coordination with ground crews and equipment operators.

What Rigging Techniques Ensure Safe Lifting?

Safe lifting relies on meticulous planning and execution using appropriate rigging techniques. This includes selecting correctly rated slings and shackles, calculating load weights and angles, ensuring proper crane/gin pole setup and capacity, using taglines for load control, and constant communication.

Rigging is a high-risk activity requiring certified expertise. Key techniques include:

- Load Calculation: Accurately determining the weight of each tower section and ensuring all lifting gear (slings, shackles, hoist lines) has a sufficient safety factor.

- Proper Slinging: Attaching slings to designated lift points on the tower section to ensure a balanced and stable lift. Sling angles must be considered as they affect the load on each leg.

- Crane/Gin Pole Setup: Ensuring the lifting equipment is on stable ground, properly leveled, and operating within its load chart limits for the required radius and height.

- Taglines: Ropes attached to the load allow ground crews to control its orientation and prevent spinning during the lift.

- Communication: Clear, constant communication between the lift director, equipment operator, and climbing crew using hand signals or radios. Rigging failures can have devastating consequences, making expertise and adherence to procedure paramount.

How Are Final Alignments and Inspections Conducted?

Final alignments involve using survey instruments (transits or total stations) to verify the tower is perfectly plumb (vertical) within specified tolerances. Inspections include checking all bolted connections for proper torque, verifying weld integrity (if applicable), and ensuring all components are installed per drawings.

Once the main structure is erected, final checks ensure it meets all specifications.

- Plumbness: Surveyors measure the verticality of the tower at multiple points. Adjustments may be made (e.g., by shimming the base plate or adjusting guy wire tension) to bring it within tolerance.

- Bolt Torque: Crews re-check the torque on all critical structural bolts using calibrated torque wrenches to ensure connections are secure.

- Component Check: A final visual inspection confirms all members, platforms, ladders, safety climbs, and other components are correctly installed.

- Documentation: All inspection results and measurements are recorded in the final turnover package. This final verification step confirms the tower is structurally sound and ready for equipment installation.

What Types of Towers Require Installation Expertise?

Professional tower installation services require expertise across the full spectrum of telecommunications tower types. Each design presents unique construction challenges related to its structure, assembly method, and foundation requirements. Experienced providers possess the knowledge and equipment to install all common tower types safely and efficiently.

How Are Monopole Towers Installed?

Monopole towers are typically installed using a crane. They arrive in large, tapered steel sections. The base section is bolted to the foundation. Subsequent sections are lifted and slid over the section below (slip-fit connection) or bolted via flange plates.

Monopoles are common in urban and suburban areas due to their smaller footprint and relatively simple appearance. Installation involves:

- Base Section: Lifting the heaviest bottom section and carefully lowering it onto the anchor bolts in the foundation. Nuts are then tightened.

- Upper Sections: Lifting each subsequent section and guiding it over the top of the lower section. The tapered design allows for a tight friction fit, sometimes supplemented by bolts at flange connections.

- Alignment: Ensuring each section is properly seated and aligned before the crane releases the load. Due to the large, heavy sections, crane access and capacity are critical planning factors.

What is Involved in Installing Self-Support Lattice Towers?

Installing self-support lattice towers involves assembling the steel framework, either piece by piece or in sections on the ground, and then lifting these into place with a crane or gin pole. Crews working at height meticulously bolt all connections together.

Lattice towers, often three or four-legged, are common for heavier loads or taller heights. Installation is more complex than monopoles:

- Assembly: Individual steel angle or tubular members are bolted together on the ground to form panels or larger sections, following detailed erection drawings.

- Lifting: Cranes (for lower heights) or gin poles (for taller structures) lift the assembled sections.

- Connection: Climbing crews guide the sections into place and install hundreds or thousands of bolts, ensuring each is properly torqued.

- Alignment: Constant checks are needed to ensure the tower legs remain plumb and the structure is not twisted during erection. This type of installation is labor-intensive and requires significant climbing and rigging expertise.

What Are the Specifics of Guyed Tower Installation?

Guyed tower installation involves erecting a slender lattice mast (similar to a self-support tower section) and stabilizing it with multiple levels of high-strength steel guy wires anchored to the ground at substantial distances from the base.

Guyed towers can achieve great heights cost-effectively but require a large land footprint for the guy anchors. Specifics include:

- Mast Erection: Often done section by section using a gin pole.

- Guy Wire Attachment: Guy wires are attached to the mast at engineered levels as erection progresses.

- Anchor Installation: Massive concrete anchors are constructed at precise locations radiating out from the tower base.

- Guy Wire Tensioning: This is a critical step. Using specialized equipment (dynamometers and chain hoists), each guy wire is carefully tensioned to the exact specification required by the design. Proper tensioning ensures the mast remains stable and plumb under wind loads. Incorrect tensioning is a major safety hazard. The engineering behind guy wire tension is complex.

Are Rooftop Installations Handled Differently?

Yes, rooftop installations are handled very differently. They require careful structural analysis of the existing building to ensure it can support the tower's weight and wind load. Specialized mounting systems (non-penetrating or structurally attached) and unique lifting methods are often needed.

Rooftop sites are common in dense urban areas. Challenges include:

- Structural Assessment: A structural engineer must verify the building's roof can handle the additional loads. Reinforcement may be necessary.

- Mounting: Non-penetrating mounts (using ballast) or mounts directly attached to the building's main structural steel are used. Waterproofing is critical.

- Lifting: Cranes with very long reaches or even helicopters may be required to lift tower components and equipment to the roof.

- Logistics: Managing materials and crew access in an occupied building requires careful coordination. These installations demand specialized planning and expertise in working with existing structures. Such projects are common in dense areas requiring specific cell site installation services.

What are the Key Safety Considerations During Installation?

Safety is the paramount consideration throughout every phase of a tower installation project. The potential hazards are significant, involving working at extreme heights, lifting heavy and awkward loads, and dealing with electrical and environmental risks. A professional installation provider operates with an uncompromising commitment to safety protocols.

Why is Fall Protection the Top Priority?

Fall protection is the top priority because falls from height are the leading cause of fatalities and serious injuries in the tower industry. Adherence to 100% fall protection protocols (using appropriate harnesses, lanyards, positioning devices, and fall arrest systems) is mandatory.

Every climber must be equipped with and properly use personal fall arrest systems (PFAS). Safety climb devices attached to the tower ladder or structure provide continuous fall protection during ascent and descent. Work positioning systems allow climbers to work hands-free securely. Rescue plans and trained rescue personnel must be on-site in case of an emergency. There is no tolerance for deviation from these life-saving procedures. Worker safety regulations are stringent for this reason.

How is Equipment and Rigging Safety Managed?

Equipment and rigging safety is managed through regular inspection and certification of all gear, adherence to engineered rigging plans, calculation of load capacities with safety factors, and use of certified riggers and signal persons.

All lifting equipment (cranes, gin poles, hoists) and rigging gear (slings, shackles, ropes) must be regularly inspected and load-tested. Rigging plans detail how each lift will be performed safely. Only trained and certified riggers should prepare loads for lifting. Clear communication protocols between the lift director, equipment operator, and signal person are essential. Overloading equipment or using damaged gear can lead to catastrophic failure.

What Role Does Weather Monitoring Play?

Weather monitoring plays a critical role. High winds, lightning, heavy rain, or icing conditions create unacceptable risks for tower work. Work must be suspended immediately when predetermined weather thresholds are exceeded.

A designated person on site is responsible for monitoring real-time weather conditions and forecasts using reliable sources (weather apps, anemometers). Specific wind speed limits are established for climbing and lifting operations. Work stops well in advance of approaching thunderstorms due to the severe lightning risk on tall metal structures. Icy conditions make climbing surfaces treacherous. Adhering to weather-related work stoppages is crucial for preventing accidents.

How Are Site Security and Access Controlled?

Site security and access control involve establishing clear work zones, restricting entry to authorized personnel only, using proper signage, and securing the site after work hours. This prevents unauthorized access and protects the public from construction hazards.

The area around the tower base and under any overhead work is designated as a restricted zone. Only essential crew members are allowed entry. Warning signs are posted. Fencing may be used to secure the perimeter. At the end of the workday, the site and all equipment are secured to prevent vandalism or unauthorized use. Maintaining a controlled site is essential for both worker and public safety.

How Does Installation Integrate with Overall Telecom Services?

Tower installation is a critical phase, but it is just one part of the broader ecosystem of telecom tower services. It follows the essential groundwork laid during site acquisition and planning. It sets the stage for the subsequent installation of electronic equipment and the long-term need for maintenance. Understanding this integration is key to appreciating the value of a comprehensive service provider.

How Does Installation Follow Site Acquisition?

Installation logically follows the successful completion of the site acquisition phase. Once the land lease is secured, zoning approvals are granted, and all necessary permits are obtained, the physical construction can begin. A seamless handover from the site acquisition team to the construction project manager is crucial for maintaining project momentum. Delays in permitting can directly impact the start date of the installation.

What Equipment Installation Happens Post-Erection?

Immediately following the successful erection and inspection of the tower structure, the equipment installation phase begins. This involves mounting antennas, running transmission lines, installing ground equipment (radios, power systems), and connecting backhaul. While sometimes performed by the same company, this often involves specialized technical crews working in coordination with the structural installation team. The tower structure provides the physical platform for this critical electronic infrastructure.

How Does Installation Set the Stage for Maintenance?

A high-quality installation sets the stage for efficient and safe long-term maintenance. A properly constructed tower with correctly installed components (ladders, safety climbs, platforms) makes future access for tower maintenance company crews safer and easier. Comprehensive documentation provided at the end of the installation (as-built drawings, inspection reports, material certifications) is vital for future structural analyses and maintenance planning. Investing in a quality installation reduces long-term maintenance costs and risks.

Why Choose an Integrated Service Provider?

Choosing an integrated service provider that handles multiple phases of the tower lifecycle – from site acquisition through installation and onto maintenance – offers significant advantages. It streamlines communication, simplifies project management, and ensures consistency in quality and safety standards across all phases. An integrated telecom infrastructure provider brings a holistic perspective, understanding how decisions made during installation impact long-term operational efficiency. This integrated approach often leads to faster deployments and lower overall project costs.

Conclusion

Professional tower installation services are fundamental to building the robust physical infrastructure that underpins modern wireless communication. This demanding work requires a unique blend of engineering knowledge, logistical expertise, specialized skills, and an unwavering commitment to safety. By adhering to meticulous planning, employing certified crews, following rigorous procedures, and ensuring quality at every step, professional installation providers deliver structures that are safe, reliable, and built to last. For telecom operators seeking to expand or enhance their networks, partnering with a qualified installation expert is not just a choice; it is an essential investment in the future of connectivity.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.