Transmission Tower Price Per Ton: 2026 Factory Direct Pricing Guide

2025-12-22

Transmission tower prices range from $800 to $1,500 per ton for standard lattice structures ordered factory direct. Tubular monopole towers cost $1,200-$2,000 per ton, while specialized high-voltage towers range $1,600-$2,500 per ton. These prices include raw materials, fabrication, hot-dip galvanization, and quality testing but exclude foundation work, installation labor, and site-specific costs.

At X.Y. Tower, we've manufactured over 40,000 tons annually since 2008, serving customers across 20+ countries. Here's what you actually need to know about transmission tower pricing—without the sales fluff.

Current Transmission Tower Pricing by Type (2026)

The market's more transparent than it used to be, but you still need to know what you're comparing. Factory direct pricing varies significantly based on structure type and specifications.

| Tower Type | Price Range ($/ton) | Typical Weight Ratio | Best For |

|---|---|---|---|

| Lattice Angle Steel | $800 - $1,500 | 0.8-1.2 tons/meter | Rural transmission, bulk orders |

| Tubular Steel | $1,200 - $2,000 | 1.0-1.4 tons/meter | Medium-voltage lines, faster installation |

| Monopole | $1,400 - $2,200 | 1.2-1.6 tons/meter | Urban areas, aesthetic requirements |

| Guyed Tower | $700 - $1,200 | 0.6-0.9 tons/meter | Large spans, minimal foundation |

Here's what matters: the per-ton price is your starting point, not your final cost. When we quote a power tower project, material cost represents about 45% of your total landed expense.

| Voltage Class | Typical Price ($/ton) | Weight Range (tons/meter) | Common Applications |

|---|---|---|---|

| 10kV - 35kV | $800 - $1,100 | 0.7 - 0.9 | Distribution networks |

| 66kV - 110kV | $1,000 - $1,400 | 0.9 - 1.1 | Regional transmission |

| 132kV - 220kV | $1,200 - $1,700 | 1.0 - 1.3 | National grid backbone |

| 330kV - 500kV | $1,500 - $2,500 | 1.2 - 1.5 | Long-distance transmission |

Understanding What's Included in Per-Ton Pricing

Most buyers get surprised when their "$1,200/ton tower" actually costs $2,100/ton delivered and installed. Let me break down where your money goes.

What IS included in factory direct per-ton pricing:

- Raw steel materials (ASTM A572 Grade 50 or equivalent)

- CNC cutting and fabrication

- Hot-dip galvanization (minimum 86μm coating)

- Quality testing and inspection

- Factory-to-port delivery (China ports)

What's NOT included:

- Foundation engineering and materials ($8,000-$35,000 per tower)

- Insulators and hardware assemblies ($150-$400 per ton)

- International shipping and import duties

- Site delivery and installation labor ($200-$500 per ton)

- Engineering and design services (5-8% of project cost)

| Cost Component | % of Total Cost | Amount (on $1,200/ton base) |

|---|---|---|

| Raw Steel Material | 40-45% | $480-$540 |

| Fabrication & Processing | 25-30% | $300-$360 |

| Hot-Dip Galvanization | 15-20% | $180-$240 |

| Quality Control & Testing | 5-8% | $60-$96 |

| Overhead & Profit | 10-15% | $120-$180 |

Real example: A 35-meter 110kV lattice tower weighing 35 tons at $1,200/ton = $42,000 base cost. Add $18,000 foundation, $8,500 hardware, $10,500 installation = $79,000 total installed cost ($2,257/ton all-in).

Transmission Tower Weight and Cost Calculation

You can estimate tower costs before getting detailed engineering. The industry standard weight-to-height ratio gives you a ballpark that's accurate within 15%.

For lattice towers, expect 0.8-1.2 tons per meter of height. Monopole towers run heavier at 1.2-1.6 tons per meter due to tubular construction.

Calculation formula:

Estimated Weight = Tower Height (m) × Weight Ratio (tons/m)

Material Cost = Estimated Weight × Price per TonExample 1: Standard 110kV Lattice Tower

- Height: 35 meters

- Weight ratio: 1.0 tons/meter (mid-range)

- Estimated weight: 35 × 1.0 = 35 tons

- Price: $1,200/ton

- Material cost: $42,000

Example 2: High-Voltage 220kV Tubular Tower

- Height: 50 meters

- Weight ratio: 1.3 tons/meter

- Estimated weight: 50 × 1.3 = 65 tons

- Price: $1,600/ton

- Material cost: $104,000

Example 3: Distribution 66kV Monopole

- Height: 25 meters

- Weight ratio: 1.4 tons/meter

- Estimated weight: 25 × 1.4 = 35 tons

- Price: $1,500/ton

- Material cost: $52,500

Variables that push weight higher: ice/wind loading zones, seismic requirements, double-circuit configurations, angle or dead-end tower types (vs. suspension towers).

| Tower Type | Weight per Meter | 30m Tower | 40m Tower | 50m Tower |

|---|---|---|---|---|

| Lattice (light duty) | 0.8 tons/m | 24 tons | 32 tons | 40 tons |

| Lattice (standard) | 1.0 tons/m | 30 tons | 40 tons | 50 tons |

| Lattice (heavy duty) | 1.2 tons/m | 36 tons | 48 tons | 60 tons |

| Tubular | 1.3 tons/m | 39 tons | 52 tons | 65 tons |

| Monopole | 1.5 tons/m | 45 tons | 60 tons | 75 tons |

Volume Pricing and MOQ (Minimum Order Quantity)

Here's where you can actually save money. Volume discounts are standard, but manufacturers structure them differently.

Most factories set MOQ at 10-20 tons minimum. You'll see the real savings kick in around 50 tons—that's typically 8-12 medium-height towers or 3-5 high-voltage structures.

| Order Quantity | Discount Level | Example Price Change | Real Savings on 100 Tons |

|---|---|---|---|

| 1-10 tons | List price | $1,200/ton | Baseline |

| 10-50 tons | 5-10% off | $1,140-$1,080/ton | $6,000-$12,000 |

| 50-200 tons | 15-25% off | $1,020-$900/ton | $18,000-$30,000 |

| 200+ tons | 30-35% off | $840-$780/ton | $36,000-$42,000 |

Project planning tip: If you're building a line with mixed tower types, combine your order to hit volume thresholds. We've manufactured projects where buyers ordered 150 tons of lattice transmission line towers plus 50 tons of substation structures—200 tons total qualified for maximum discount across both specifications.

Single 35-ton tower scenario: 1 tower × 35 tons × $1,200/ton = $42,000

Bulk project scenario: 15 towers × 35 tons each = 525 tons total

- Volume price: $840/ton (30% discount)

- Total cost: 525 × $840 = $441,000

- Per-tower cost: $441,000 ÷ 15 = $29,400 (saves $12,600 per tower)

Price Factors: What Makes Towers Cost More or Less

Six factors drive 90% of price variation between quotes.

1. Steel Grade Quality ASTM A572 Grade 50 is industry standard (50 ksi yield strength). Upgrading to Grade 65 adds 10-15% to material cost but allows lighter designs. Chinese manufacturers typically use GB/T 700 Q345 or Q420 equivalent grades.

2. Voltage Class Impact Higher voltage doesn't just mean taller towers—it means heavier duty construction. A 500kV tower uses 30-40% more steel per meter than a 110kV tower of equal height due to larger cross-sections and increased safety factors.

3. Galvanization Thickness Standard hot-dip galvanizing provides 86μm average coating (per ISO 1461). Heavy-duty specification at 120μm+ adds $150-$250/ton but extends service life from 40 to 50+ years. Over 40 years, that's a 25% better investment. Our galvanizing factory processes all towers through automated lines maintaining consistent 100-120μm coating thickness.

4. Design Complexity

- Suspension towers (standard): Baseline pricing

- Angle towers (15-45° line turns): +12-18% cost

- Dead-end/strain towers: +18-25% cost

- Transposition towers: +20-30% cost

5. Manufacturing Standards & Certifications ISO 9001 certified production adds 8-12% to base cost but eliminates field failures. Third-party testing (SGS, TÜV) adds another 3-5%. Non-certified manufacturers might quote 20% lower, but you're gambling on quality.

6. Geographic & Market Factors Raw steel prices fluctuate. Current market (December 2025): $520-$580/ton for structural steel. When steel hits $650/ton, expect transmission tower prices to rise 12-15%.

| Specification Upgrade | Standard Option | Premium Option | Price Impact |

|---|---|---|---|

| Steel Grade | Q345 (Grade 50) | Q420 (Grade 65) | +$120-180/ton |

| Galvanization | 86μm coating | 120μm coating | +$150-250/ton |

| Tower Type | Suspension | Dead-end | +$180-300/ton |

| Certification | Factory QC only | ISO + SGS testing | +$100-150/ton |

| Wind/Ice Loading | Standard zone | Extreme zone | +$200-350/ton |

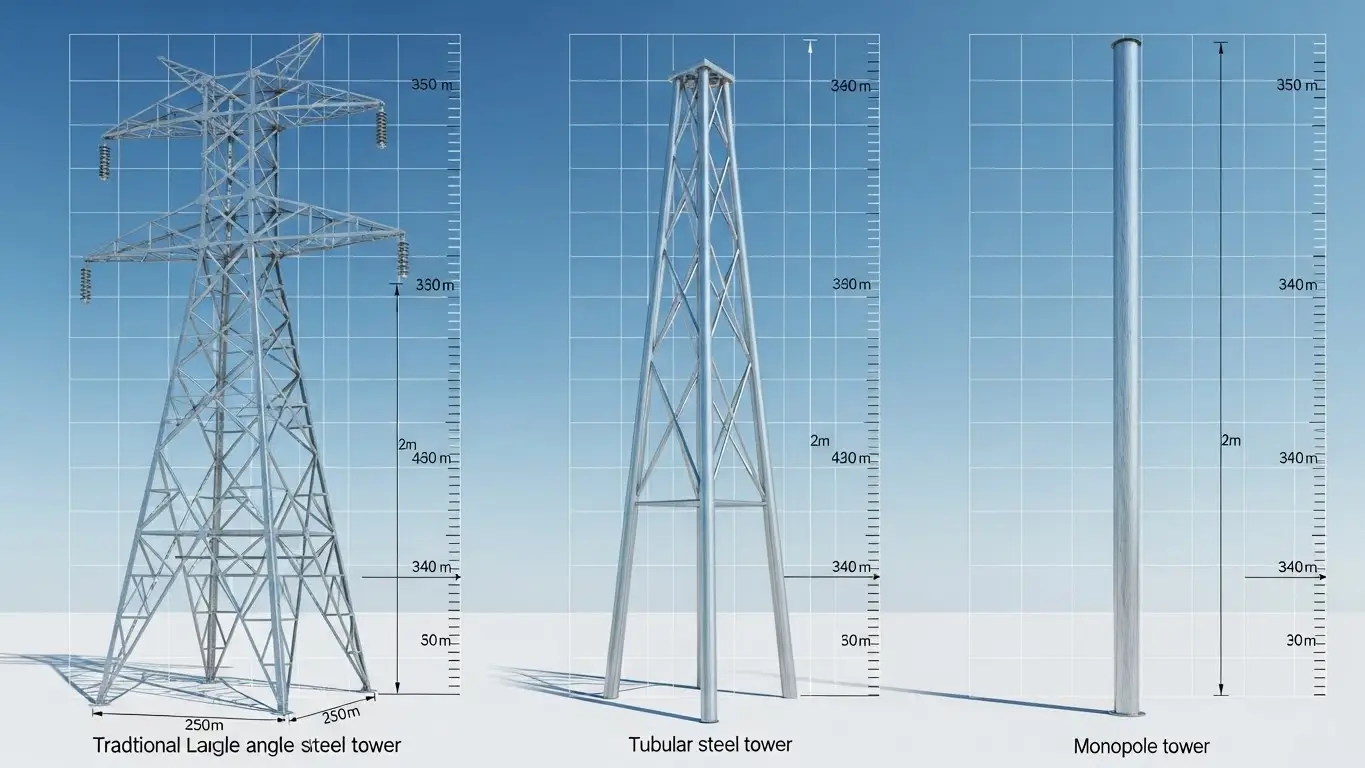

Lattice vs Tubular vs Monopole: Cost Comparison

Each tower type has a different total cost equation. Material price is only part of the story.

Lattice Angle Steel Towers

- Material: $800-$1,500/ton

- Installation labor: $350-$500/ton (complex assembly)

- Foundation: $15,000-$30,000 (four-leg design)

- Land use: 15-25 square meters footprint

- Best for: Rural areas, bulk transmission projects, where land is available

Tubular Steel Towers

- Material: $1,200-$2,000/ton

- Installation labor: $250-$400/ton (pre-fabricated sections)

- Foundation: $12,000-$25,000 (three-leg typical)

- Land use: 10-18 square meters

- Best for: Balanced projects, medium-voltage lines, 66kV-220kV applications

Monopole Towers

- Material: $1,400-$2,200/ton

- Installation labor: $200-$300/ton (fastest installation)

- Foundation: $18,000-$35,000 (single large pier)

- Land use: 4-9 square meters

- Best for: Urban corridors, telecommunication applications, space-constrained sites

| Factor | Lattice | Tubular | Monopole |

|---|---|---|---|

| Material Cost per Ton | $800-$1,500 | $1,200-$2,000 | $1,400-$2,200 |

| Installation Time | 3-5 days | 2-3 days | 1-2 days |

| Foundation Cost | High | Medium | High |

| Maintenance Access | Climbable | Climbable | Requires lift equipment |

| Visual Impact | Industrial | Moderate | Minimal |

| 40-Year TCO (35m tower) | $95,000-$125,000 | $110,000-$145,000 | $125,000-$165,000 |

Real project costs including everything:

35-meter 110kV lattice tower:

- 35 tons × $1,100/ton = $38,500 (materials)

- Foundation: $22,000

- Hardware: $8,400 ($240/ton)

- Installation: $14,000 ($400/ton)

- Total: $82,900

35-meter monopole tower:

- 50 tons × $1,600/ton = $80,000 (materials)

- Foundation: $28,000

- Hardware: $12,000 ($240/ton)

- Installation: $12,500 ($250/ton)

- Total: $132,500

The monopole costs 60% more upfront but installs in half the time. For urban projects with high labor costs and site access restrictions, monopoles often make economic sense despite higher material pricing.

Hidden Costs and Budget Planning

Every transmission project has costs beyond the tower price. Budget for these or face project delays.

Foundation Costs: $8,000-$35,000 per tower

- Soil conditions drive this range wildly

- Rock excavation: +40-60% vs. normal soil

- Seismic zones: +25-35% for enhanced design

- Groundwater issues: +30-50% for dewatering

Insulators and Hardware: $150-$400 per ton of tower weight

- Suspension insulators: $80-$150 per string

- Strain insulators: $120-$200 per string

- Hardware assemblies: $60-$100 per tower

- Tower steel fittings and accessories vary by voltage

Transportation: $50-$150 per ton

- Factory to port: Usually included in FOB price

- Port to site: Your responsibility, distance-dependent

- Oversized load permits: $500-$2,000 per truck in some regions

- Remote site access: Can double transport costs

Installation Labor: $200-$500 per ton

- Skilled tower crews: $350-$500/ton

- Standard crews: $250-$350/ton

- Remote locations: +30-40% premium

- Helicopter assembly (extreme terrain): $1,500-$3,000/ton

Engineering and Design: 5-8% of total project cost

- Line routing studies

- Load calculations and modeling

- Permit drawings and submissions

- As-built documentation

Testing and Commissioning: $2,000-$5,000 per tower

- Foundation testing

- Grounding verification

- Structural plumbness checks

- Load testing (sample towers)

| Cost Category | Per Tower Range | Percentage of Total | Example (35m 110kV) |

|---|---|---|---|

| Tower Materials | $35,000-$55,000 | 45-50% | $42,000 |

| Foundation | $15,000-$30,000 | 18-22% | $20,000 |

| Hardware/Insulators | $8,000-$15,000 | 10-12% | $10,000 |

| Installation Labor | $10,000-$18,000 | 12-15% | $12,000 |

| Engineering | $4,000-$8,000 | 5-8% | $5,000 |

| Testing/Commissioning | $2,000-$5,000 | 2-4% | $3,000 |

| TOTAL INSTALLED | $74,000-$131,000 | 100% | $92,000 |

Budget contingency recommendation: Add 15-20% for unforeseen conditions. We've seen projects hit unexpected rock layers, requiring blasting that added $12,000 per foundation.

How to Get Accurate Transmission Tower Quotes

Bad specifications = useless quotes. Give manufacturers this information upfront:

Critical specification checklist:

- Voltage class and circuit configuration (single/double circuit)

- Tower height and type preference (lattice/tubular/monopole)

- Wind and ice loading requirements (per IEC 60826 or local standard)

- Soil bearing capacity (for foundation design integration)

- Total project quantity (enables volume pricing)

- Delivery timeline requirements (affects production scheduling)

- Quality standards needed (ASTM, BS, IEC, GB specifications)

- Certifications required (ISO 9001, third-party testing)

Red flags in quotes:

- Prices 30%+ below market average (quality concerns)

- Missing galvanization specifications

- No mention of steel grade or thickness

- Vague delivery terms ("approximately...")

- No warranty details

- Unwillingness to provide mill test certificates

Questions to ask before ordering:

- What's your typical galvanization thickness? (Want 100μm+ answer)

- Can you provide factory audit reports?

- What's your defect rate on recent projects? (Should be <2%)

- Do you maintain replacement part inventory?

- What payment terms do you offer? (Standard is 30-40% deposit, balance before shipment)

Lead time expectations: 45-60 days for standard lattice towers, 60-90 days for custom monopole designs. Our tower design services can finalize engineering in 2-3 weeks if you have site data ready.

Quality Standards and Certifications Impact on Price

Certifications cost money but prevent expensive failures. Here's what matters:

ASTM A572 Grade 50 - Structural steel minimum standard. Specifies 50 ksi (345 MPa) yield strength. Non-negotiable for transmission towers.

ISO 1461 - Hot-dip galvanizing standard. Specifies minimum 86μm average coating thickness, with local minimum of 70μm. Quality factories exceed this at 100-120μm.

IEC 60826 - Design loads for overhead transmission line equipment. Covers wind, ice, temperature effects. Critical for international projects.

ISO 9001 - Quality management system certification. Shows manufacturer has documented processes, not just random fabrication.

GB/T 2694 - Chinese national standard for transmission tower manufacturing. Most Asian manufacturers work to this standard. Equivalent to international specs when properly implemented.

| Certification | Purpose | Price Premium | When It Matters |

|---|---|---|---|

| ASTM A572 | Steel quality guarantee | Baseline | Always required |

| ISO 1461 | Galvanization quality | +5-8% | Corrosive environments |

| IEC 60826 | Design load standard | +3-5% | International projects |

| ISO 9001 | Process quality | +8-12% | Large projects, utilities |

| SGS/TÜV Testing | Third-party verification | +4-6% | High-risk applications |

Certified manufacturing adds 8-12% to base cost. Worth it? Over 40 years, certified towers have 60-70% fewer failures than non-certified equivalents. A single emergency tower replacement costs 3-5x normal pricing.

X.Y. Tower maintains ISO 9001:2015 certification with annual audits. Our quality control catches issues before shipping—saving you field remediation costs that can run $15,000-$30,000 per tower.

Regional Manufacturing and Pricing Differences

China dominates global transmission tower manufacturing with 60%+ market share. Here's the real comparison across regions:

China (Factory Direct)

- Price range: $800-$1,200/ton for standard specifications

- Quality: ISO-certified factories match international standards

- Lead time: 45-75 days

- Advantages: Cost-effective, high volume capacity, established supply chains

- Considerations: Communication, import logistics, quality verification needed

India

- Price range: $900-$1,400/ton

- Quality: Improving rapidly, good for regional projects

- Lead time: 60-90 days

- Advantages: English-speaking, growing capacity

- Considerations: Less export experience than Chinese manufacturers

Southeast Asia (Vietnam, Thailand)

- Price range: $950-$1,500/ton

- Quality: Variable by manufacturer

- Lead time: 60-100 days

- Advantages: Diversification from China

- Considerations: Smaller production capacity

Europe (Poland, Turkey, Spain)

- Price range: $1,600-$2,500/ton

- Quality: Excellent, strict regulatory compliance

- Lead time: 90-120 days

- Advantages: EU standards compliance built-in

- Considerations: 60-100% premium over Asian manufacturing

North America

- Price range: $1,800-$3,000/ton

- Quality: High, domestic standards compliance

- Lead time: 120-180 days

- Advantages: No import hassles, local support

- Considerations: Limited capacity, highest cost

| Region | Price/Ton | Lead Time | Quality Tier | Best Application |

|---|---|---|---|---|

| China (factory direct) | $800-$1,200 | 45-75 days | High (certified) | Cost-sensitive bulk projects |

| India | $900-$1,400 | 60-90 days | Medium-High | South Asian regional projects |

| Southeast Asia | $950-$1,500 | 60-100 days | Medium | Supply chain diversification |

| Europe | $1,600-$2,500 | 90-120 days | Excellent | EU projects, strict compliance |

| North America | $1,800-$3,000 | 120-180 days | Excellent | Domestic projects, fast support |

Import considerations beyond price:

- Ocean freight: $80-$150 per ton (Asia to Africa/Americas)

- Import duties: 0-15% depending on country and trade agreements

- Customs/documentation: $500-$2,000 per shipment

- Quality inspection: $1,500-$5,000 for third-party verification

- Communication and time zones: Can add weeks to project timeline

Total landed cost from Chinese factory to African site: $1,200/ton FOB + $120/ton freight + $150/ton duties + $80/ton logistics = $1,550/ton delivered. Still 35-40% below European manufacturing.

Long-Term Cost Considerations and ROI

You're not buying a 5-year asset. Transmission towers last 40-50 years with proper maintenance.

Lifespan analysis:

- Standard galvanization (86μm): 35-40 years in normal environments

- Heavy galvanization (120μm): 45-50 years

- Coastal/corrosive environments: Reduce estimates by 20-25%

Annual amortized cost example:

- $1,200/ton tower cost

- 45-year service life

- Annual cost: $26.67 per ton per year

- For 35-ton tower: $933 annually

Compare to:

- Cheaper $900/ton tower with 30-year life: $1,050 annually (13% worse ROI)

- Premium $1,500/ton tower with 50-year life: $1,050 annually (same ROI but higher capacity/reliability)

Maintenance costs: <3% annually

- Visual inspections: $500-$1,000 per tower every 2 years

- Bolt retorquing: Every 5 years after installation

- Galvanization touch-up: $800-$1,500 per tower at 20-25 years

- Structural repairs: <$300 per tower annually (average across fleet)

Failure costs to avoid:

- Emergency tower replacement: $150,000-$400,000 (materials + mobilization + outage costs)

- System outage losses: $25,000-$100,000 per hour for major transmission lines

- Reputation damage: Immeasurable for utility companies

Upgrade capability planning: Smart buyers design for future capacity. Adding 15% weight capacity during initial design costs $80-$120/ton extra. Retrofitting later costs $400-$600/ton plus reinstallation.

| Investment Scenario | Upfront Cost | Service Life | Annual Cost | 40-Year TCO |

|---|---|---|---|---|

| Budget Option | $900/ton | 30 years | $1,050/ton/yr | $150,000 (35-ton tower) |

| Standard Quality | $1,200/ton | 40 years | $840/ton/yr | $147,000 |

| Premium Quality | $1,500/ton | 50 years | $840/ton/yr | $147,000 |

| Ultra-Premium | $1,800/ton | 50 years | $1,008/ton/yr | $176,400 |

ROI insight: The sweet spot is high-quality manufacturing with heavy galvanization. That $1,200-$1,400/ton tower with 120μm coating delivers the best 40-year value.

Projects like our railway electrification tower installations in Africa demonstrate this—20-year-old structures still showing <5% galvanization degradation.

Getting the Best Value: Factory Direct Procurement Tips

Eliminate middlemen and save 20-30%. Here's how we work with direct buyers:

Why buy factory direct:

- Distributor markup: 25-35% on average

- Better communication on specifications

- Flexible customization options

- Direct warranty and support

- Volume pricing negotiation

Vetting manufacturers (our clients use this checklist):

- Factory visit if possible - Virtual tour minimum

- Production capacity verification - Ask for recent shipment proof

- Reference customers in your region - Get 2-3 contacts

- Sample testing - Order 1-2 tons for laboratory analysis before bulk order

- Quality certifications - Request current ISO, CE, or equivalent certificates

- Financial stability - 5+ years in business preferred

Managing international procurement:

- Use Letter of Credit (LC) payment terms for first orders (protects both parties)

- Hire third-party inspection (SGS, Bureau Veritas) for $3,000-$5,000

- Specify exact standards in contract (ASTM numbers, not just "high quality steel")

- Include penalty clauses for late delivery (2-3% per week typical)

- Require 2-year warranty minimum (structural defects, galvanization)

When distributor markup IS worth it:

- Orders under 20 tons (factory MOQ challenges)

- Need immediate delivery (distributors stock inventory)

- Require local technical support

- First-time imports (distributor handles logistics)

- Want consolidated orders across multiple manufacturers

Documentation requirements:

- Mill test certificates for steel

- Galvanization thickness reports

- Dimensional inspection reports

- Packing list and weight certificates

- Origin certificates (for customs)

- Warranty documentation

Common procurement mistakes we see:

- Accepting verbal specifications - Get everything in writing

- Not specifying galvanization thickness - "Hot-dip galvanized" isn't specific enough

- Ignoring payment terms impact - 100% prepayment might get 3-5% discount

- Skipping third-party inspection - $4,000 inspection catches $50,000 problems

- Unrealistic delivery timelines - Custom designs need 75-90 days minimum

Frequently Asked Questions

Standard lattice transmission towers cost $800-$1,500 per ton factory direct, with tubular monopole designs ranging $1,200-$2,000 per ton. Pricing depends on voltage class (10kV to 500kV), order quantity, quality specifications, and manufacturing location. Bulk orders of 50+ tons typically receive 15-25% volume discounts from list prices.

No, per-ton pricing covers only the tower structure: raw materials, fabrication, galvanization, and factory delivery. Installation labor adds $200-$500 per ton. Foundation work costs $8,000-$35,000 per tower separately. Insulators and hardware add $150-$400 per ton. Total installed cost typically runs 80-150% higher than base tower material pricing.

Transmission tower weight follows the industry standard of 0.8-1.2 tons per meter height for lattice designs. A 35-meter 110kV tower weighs 28-42 tons typically. A 50-meter 220kV tower weighs 45-60 tons. Actual weight depends on voltage class, design loads for wind and ice, structural type, and whether it's single or double-circuit configuration.

Chinese factory-direct transmission towers cost 40-60% less than Western manufacturers ($800-$1,200/ton versus $1,400-$2,500/ton). However, total landed costs including ocean freight, import duties, certifications, and quality assurance narrow this gap to 30-45%. ISO 9001 certified Chinese manufacturers deliver competitive quality at significant savings for international projects.

Five factors drive most price variation: (1) Order volume - bulk discounts of 15-35% available at 50+ tons, (2) Steel grade quality - premium ASTM A572 Grade 65 adds 10-15%, (3) Galvanization thickness - heavy-duty 120μm coating adds $150-250/ton, (4) Voltage class - 500kV requires 30-40% more material than 110kV, (5) Design complexity - angle and dead-end towers cost 15-25% more than standard suspension towers.

Start with tower weight: height in meters × 0.8-1.2 tons/meter for lattice design. Multiply weight by price per ton ($800-$1,500). Add foundation ($8,000-$35,000 each), hardware ($150-$400/ton), installation labor ($200-$500/ton), and engineering services (5-8% of total). Example: 35m tower = 35 tons × $1,200/ton + $20,000 foundation + $10,000 hardware + $12,000 installation = $84,000 complete.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.