Transmission Tower Weight Per Meter: Complete Voltage-Based Specification Guide

2025-12-23

Transmission tower weight per meter varies dramatically by voltage level: 35kV towers average 100-180 kg/m, 66kV systems run 150-250 kg/m, 110kV towers range 200-450 kg/m, 220kV structures reach 350-600 kg/m, and 500kV ultra-high voltage towers require 500-800 kg/m. This weight increases proportionally with voltage due to enhanced structural requirements, larger conductor spacing, and greater safety clearances mandated by ISO and ASTM standards.

Over our 17 years manufacturing transmission line towers at X.Y. Tower, we've produced over 680,000 tons of steel structures for projects across 20+ countries. One metric procurement managers consistently need—but rarely find clearly documented—is weight per meter. It's the foundation for calculating transportation costs, foundation requirements, and total project budgets.

Here's everything you need to know about tower weight specifications, straight from our engineering team's design data.

Transmission Tower Weight Per Meter by Voltage Level

The relationship between voltage and weight isn't linear—it accelerates as voltage increases. A 220kV tower doesn't just weigh twice what a 110kV tower does per meter; it's often 50-80% heavier due to structural complexity.

| Voltage Level | Suspension Tower (kg/m) | Dead-End Tower (kg/m) | Typical Height Range | Total Weight Range | Primary Application |

|---|---|---|---|---|---|

| 35kV | 100-140 | 140-180 | 14-18m | 1,760-3,186 kg | Rural distribution |

| 66kV | 150-200 | 200-250 | 15-25m | 3,000-6,250 kg | Sub-transmission |

| 110kV | 200-300 | 300-450 | 20-40m | 5,000-18,000 kg | Regional transmission |

| 220kV | 350-450 | 450-600 | 45-60m | 15,750-36,000 kg | High voltage grid |

| 500kV | 500-650 | 650-800 | 60-80m | 30,000-64,000 kg | Extra high voltage |

Suspension towers handle straight runs with minimal line deviation (up to 2°). They're your baseline. Dead-end towers need 40-60% more steel per meter because they resist the full conductor tension—critical at line terminals and major direction changes.

Our 110kV transmission towers typically average 250-280 kg/m for suspension types. That's a 30-meter tower weighing 7,500-8,400 kg before conductors and insulators.

How to Calculate Tower Weight Per Meter

The formula is straightforward, but getting accurate inputs matters more than most buyers realize.

Weight per meter = Total tower body weight (kg) ÷ Tower height (m)

Critical: Use the tower body weight only. Exclude foundations, stubs below ground level, conductors, insulators, and hardware. Including these skews your calculations for foundation design and transportation planning.

Example Calculation #1: 35kV Rural Tower

- Total tower weight: 1,762 kg

- Height: 14 meters

- Weight per meter: 1,762 ÷ 14 = 126 kg/m

This matches our standard 35kV single-circuit suspension tower design using Q235B steel.

Example Calculation #2: 110kV Suburban Project

- Total tower weight: 12,000 kg

- Height: 30 meters

- Weight per meter: 12,000 ÷ 30 = 400 kg/m

This represents a dead-end tower handling a 15° line deviation with enhanced wind loading (Zone IV per IS 802:2015).

Example Calculation #3: 220kV Interstate Line

- Total tower weight: 24,000 kg

- Height: 52 meters

- Weight per meter: 24,000 ÷ 52 = 462 kg/m

Double-circuit configuration adds significant cross-arm weight, pushing this into the upper range for 220kV applications.

From our production data processing 40,000 tons annually, weight per meter calculations accurate to within ±5% require certified scale measurements. Drawing-based estimates often understate actual weight by 8-12% due to weld material, galvanizing thickness, and manufacturing tolerances.

Material Grade Impact on Weight Ratios

Steel grade selection has shocked more than a few project managers when they realize a "heavier" grade actually reduces total tower weight.

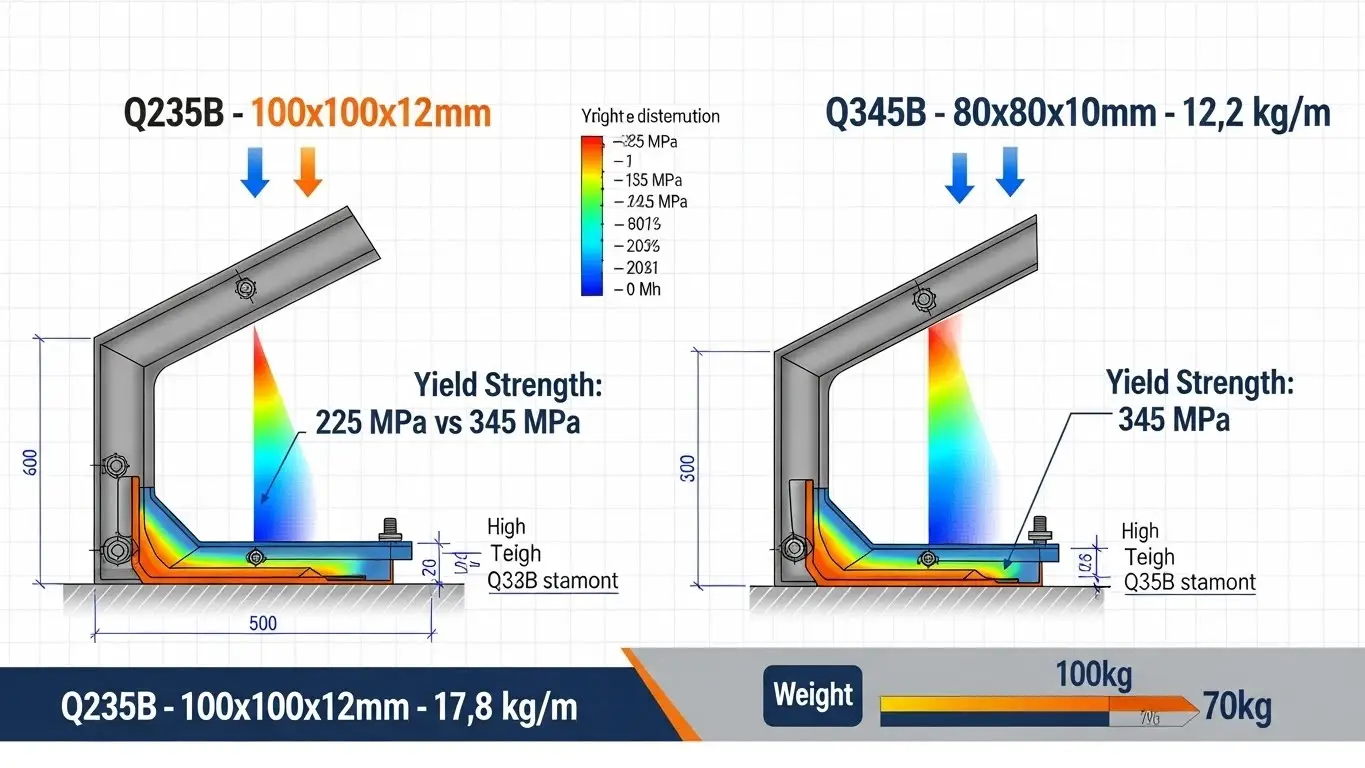

The physics: Higher yield strength means thinner members achieve the same structural capacity. Q345B steel at 345 MPa yield strength needs 30-40% less cross-sectional area than Q235B at 235 MPa for identical load resistance.

| Material | Yield Strength | Density | Weight vs. Q235B | Cost Premium | Best Use Case |

|---|---|---|---|---|---|

| Q235B (ASTM A36) | 235 MPa | 7,850 kg/m³ | 100% (baseline) | Lowest | Standard designs, low wind zones |

| Q345B (A572 Gr.50) | 345 MPa | 7,850 kg/m³ | 60-70% | +15-20% | Optimized designs, most common |

| Q420B | 420 MPa | 7,850 kg/m³ | 50-60% | +30-40% | Special applications, extreme loads |

| Aluminum 6061-T6 | 240 MPa | 2,700 kg/m³ | 25-40% | +200-300% | Helicopter installation, mountains |

Our engineering team defaults to Q345B for nearly all export projects. The 15-20% material cost premium gets recovered through reduced transportation (fewer trucks), smaller crane requirements during installation, and lower foundation costs.

A 110kV tower shifting from Q235B to Q345B drops from 320 kg/m to 210 kg/m. That's 3,300 kg saved on a 30-meter tower—enough to reduce foundation concrete volume by 15-20% depending on soil bearing capacity.

Hot-dip galvanizing adds 3-5% to total weight. At our galvanizing facility in Deyang, we maintain 86μm minimum coating thickness per ASTM A123. For a 300 kg/m tower, expect galvanizing to add 9-15 kg/m.

Weight Distribution: Where the Steel Goes

Understanding weight distribution helps optimize designs and identify cost-saving opportunities.

In a typical 110kV suspension tower:

- Main legs: 40-45% of total weight

- Cross-arms: 18-22%

- Bracing members: 25-30%

- Gusset plates and connections: 8-12%

The lower panels carry exponentially more load. Bottom panel leg members might use 100×100×10mm angle steel, while top panels step down to 65×65×6mm.

Weight per meter isn't constant from top to bottom. The bottom third of a tower typically carries 45-50% of total weight, middle third 30-35%, and top third 20-25%.

This matters for transportation planning. You can't simply divide total weight by height and assume uniform distribution when selecting crane capacities or planning panel-by-panel erection sequences.

Single-Circuit vs. Double-Circuit Weight Comparison

Adding a second circuit doesn't double the weight—it increases it by 40-65%.

The math: You need two sets of cross-arms and conductors, but you're using the same leg structure. The main legs gain maybe 15-20% more weight to handle increased lateral loads, but you're not building two separate towers.

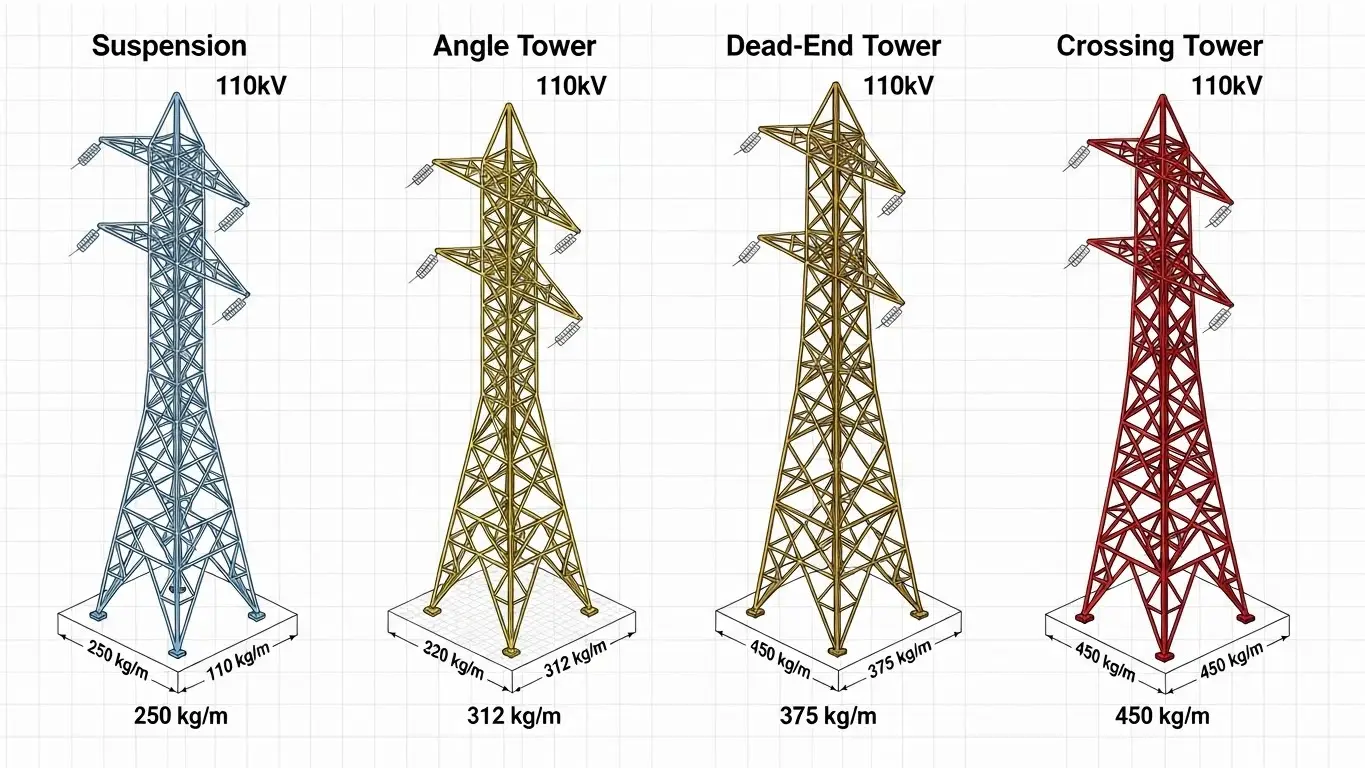

110kV Example:

- Single-circuit suspension: 250 kg/m

- Double-circuit suspension: 375-400 kg/m (+50-60%)

220kV Example:

- Single-circuit: 400 kg/m

- Double-circuit: 600-650 kg/m (+50-63%)

Double-circuit makes economic sense when right-of-way costs are high or when you're planning capacity expansion within 5-7 years. The upfront weight premium pays back through avoided second tower line construction.

We've supplied double-circuit 66kV transmission towers for urban corridors in Southeast Asia where land acquisition costs exceeded $2M per kilometer. The extra 2-3 tons per tower cost $5,000-7,000, while a second separate tower line would've required another $400,000/km in right-of-way.

Environmental Loading and Weight Specifications

Wind and ice loading requirements can push tower weights up 15-40% versus baseline designs.

IS 802:2015 defines five wind zones. A tower designed for Zone I (33 m/s basic wind speed) might weigh 300 kg/m. That same electrical specification in Zone V (55 m/s) could require 375-420 kg/m.

Ice loading adds even more. The standard 12mm radial ice thickness assumption increases conductor weight by 2-3 times during ice storms. Towers must withstand this without permanent deformation.

| Environmental Factor | Weight Impact | Typical Regions |

|---|---|---|

| Wind Zone I-II | Baseline | Inland plains |

| Wind Zone III-IV | +8-15% | Coastal areas |

| Wind Zone V | +15-25% | Typhoon-prone coasts |

| Heavy ice loading | +12-20% | Northern climates, mountains |

| Seismic Zone IV-V | +8-15% | Earthquake-prone regions |

Combined loadings multiply effects. A tower designed for Zone IV wind + heavy ice + seismic loading might need 35-40% more steel than the same voltage level in benign conditions.

Our ISO 9001:2015 certified engineering process runs full finite element analysis (FEA) on every custom tower design to optimize weight while meeting all safety factors per IEC 60826 standards.

Weight Per Meter Cost Implications

Every 100 kg/m reduction creates measurable project savings across multiple categories.

Material Costs

At current steel prices ($950-1,500 per ton FOB China for galvanized towers), each 100 kg/m saved on a 30-meter tower is 3,000 kg × $1.15/kg = $3,450 per tower.

A 100-tower project saves $345,000 in material costs alone.

Transportation Costs

Container shipping charges by weight and volume. Lighter towers mean more units per container.

Standard 40-foot containers max out at 26-27 metric tons payload. Reducing tower weight from 12 tons to 9 tons means fitting 3 towers instead of 2—a 50% shipping efficiency gain.

Per-tower shipping cost drops from $800 to $533 for our typical African export routes.

Foundation Costs

Tower weight directly determines foundation size and concrete volume. Each 100 kg/m reduction (3,000 kg on a 30m tower) cuts foundation loads proportionally.

For soil bearing capacity of 150 kPa, reducing tower weight from 12 to 9 tons can shrink foundation footprint from 4.8m × 4.8m to 4.2m × 4.2m. That's 40% less concrete volume and 35% less excavation.

Foundation cost savings: $1,200-1,800 per tower depending on region.

Installation Costs

Lighter towers enable smaller cranes. A 120-ton crane daily rate runs $3,000-5,000 in most markets. If tower weight reduction lets you use an 80-ton crane at $1,800-2,500 per day, savings multiply across 30-60 day installation periods.

Labor efficiency improves too. Crews erect lighter panels faster—typically 15-20% time savings translates directly to reduced labor costs.

Tower Type Weight Variations

Not all towers at the same voltage weigh the same per meter. Function drives weight requirements.

Suspension Towers (Type A): Baseline weight. Handle straight runs up to 2° deviation.

Small Angle Towers (Type B): +15-25% weight. Support 2-15° line deviations with light strain insulators.

Medium Angle Towers (Type C): +25-40% weight. Handle 15-30° turns with full strain insulator strings.

Dead-End Towers (Type D): +40-60% weight. Terminate lines or anchor before major crossings. Must resist full conductor tension.

Crossing Towers: +50-100% weight. Extra height for river, highway, or railway crossings requires extended leg sections and reinforced members.

A 110kV suspension tower at 250 kg/m becomes a dead-end tower at 375-400 kg/m—identical voltage and environmental loading, but massively different structural demands.

When specifying towers, you'll need roughly:

- 60-70% suspension types

- 15-20% small angle types

- 8-12% medium angle/dead-end types

- 2-5% crossing or special towers

Mix these percentages with voltage-specific weights to calculate average project weight per meter accurately.

Standards and Weight Verification

Three standard families govern transmission tower design globally. Weight specifications differ slightly under each.

IS 802 (Part 1/Sec 1):2015 - Indian standards

- Most comprehensive weight calculation methodology

- Includes empirical formulas for preliminary weight estimation

- Our engineering team cross-references all Asian export projects against IS codes

GB 50017-2017 - Chinese specifications

- Slightly more conservative member sizing in wind loading

- Tends to produce 5-8% heavier designs than IS codes for equivalent conditions

- Mandatory for domestic Chinese projects

ASTM/ASCE Standards - North American practice

- ASCE Manual 52 provides detailed design guidance

- ASTM A123 governs galvanizing which adds 3-5% weight

- Generally aligns closely with IS codes for final tower weights

For high-voltage steel transmission towers exported internationally, we certify designs under the client's specified standard but verify against all three to ensure no hidden discrepancies.

Testing protocols matter. Load test requirements vary by standard, but all require proof loading to 1.5× design loads minimum. This verification catches any weight distribution issues before towers ship.

Our quality control department maintains ±3% weight tolerance on all manufactured towers versus approved drawings—industry-leading precision enabled by automated CNC cutting and our 10 automated production lines.

How to Specify Weight in Technical Proposals

When requesting quotes, clarity on weight specifications prevents misunderstandings that delay projects.

Include in your RFQ:

- Tower body weight excluding foundations, stubs, conductors, and hardware

- Weight tolerance range (we recommend ±5% maximum)

- Steel grade specification (Q235B, Q345B, or equivalent per ASTM)

- Whether galvanizing weight is included

- Required documentation (certified scale tickets, material certificates)

Red flags in proposals:

- Weights 15%+ lighter than industry norms without high-strength steel specification

- No breakdown between tower body and foundation/hardware

- Missing steel grade specifications

- Galvanizing thickness below 86μm (ASTM A123 minimum)

Proper weight specifications also drive bolt quantities for tower assembly. Heavier members need larger bolts and more connection points—another cost factor tied directly to weight per meter.

Real-World Weight Examples from X.Y. Tower Projects

These specifications come from our actual manufacturing data, not theoretical calculations.

Project 1: 35kV Rural Electrification (Tanzania)

- Tower type: Single-circuit suspension

- Height: 16 meters

- Total weight: 2,100 kg

- Weight per meter: 131 kg/m

- Steel grade: Q235B

- Outcome: Successfully withstood Zone III wind loading during 2023 cyclone season

Project 2: 110kV Suburban Expansion (Philippines)

- Tower type: Double-circuit dead-end

- Height: 35 meters

- Total weight: 14,700 kg

- Weight per meter: 420 kg/m

- Steel grade: Q345B

- Special notes: Typhoon zone design, 86μm galvanizing survived 3 years coastal exposure with zero rust

Project 3: 220kV Interstate Transmission (Kenya)

- Tower type: Single-circuit suspension

- Height: 48 meters

- Total weight: 19,200 kg

- Weight per meter: 400 kg/m

- Steel grade: Q345B

- Achievement: Installed via helicopter in Rift Valley highlands—weight savings critical to installation feasibility

Project 4: 66kV Mountain Line (Nepal)

- Tower type: Single-circuit angle (15°)

- Height: 22 meters

- Total weight: 4,620 kg (aluminum 6061-T6)

- Weight per meter: 210 kg/m (equivalent steel would be 550 kg/m)

- Special notes: 62% weight reduction enabled helicopter installation at 3,200m altitude

These real-world examples demonstrate why weight per meter calculations must account for specific project conditions—not just voltage levels.

Frequently Asked Questions

110kV transmission towers typically weigh 200-450 kg per meter depending on type and loading conditions. Suspension towers average 200-300 kg/m while dead-end towers reach 300-450 kg/m. Our standard 110kV suspension design using Q345B steel weighs 250-280 kg/m for Zone III wind and moderate ice loading per IS 802:2015 specifications.

Divide the total tower body weight by its height in meters, excluding foundations, below-ground stubs, conductors, insulators, and hardware. For example, a 12,000 kg tower standing 30 meters tall = 400 kg/m. Obtain certified scale measurements rather than drawing-based estimates which typically understate actual weight by 8-12% due to welds, galvanizing, and manufacturing tolerances.

Higher voltage requires proportionally larger conductor spacing (2m at 66kV vs. 6m+ at 500kV) and longer insulator strings (1.2m at 110kV vs. 3-5m at 500kV), driving wider cross-arms and heavier structural members. Additionally, mechanical loads from heavier bundled conductors and stricter safety clearances per IEC 60826 mandate more robust construction beyond what simple height scaling would predict.

Q345B steel towers (ASTM A572 Grade 50 equivalent) weigh 30-40% less than Q235B equivalents due to 47% higher yield strength (345 MPa vs. 235 MPa). A 110kV tower requiring 300 kg/m in Q235B needs only 200-220 kg/m in Q345B for identical structural capacity, though Q345B costs 15-20% more per ton. The material cost premium is typically recovered through transportation and foundation savings.

Hot-dip galvanizing per ASTM A123 standard (minimum 86μm coating thickness) adds approximately 3-5% to total tower weight. For a 300 kg/m tower, expect galvanizing to contribute 9-15 kg/m additional weight. This must be included in foundation design calculations but provides 30+ years of corrosion protection essential for tower longevity in harsh environments.

Primary factors include tower type (suspension vs. dead-end), environmental loading (wind zones I-V, ice regions), single vs. double-circuit configuration, steel grade selection, and special applications like river crossings. A baseline 110kV suspension tower at 250 kg/m can reach 420 kg/m as a double-circuit dead-end in Zone V with heavy ice loading—68% heavier while serving the same voltage.

Each 100 kg/m weight reduction (3,000 kg on a 30m tower) proportionally reduces foundation loads, enabling smaller footprint designs. For soil bearing capacity of 150 kPa, reducing tower weight from 12 to 9 tons can shrink foundations from 4.8m × 4.8m to 4.2m × 4.2m—saving 40% concrete volume and $1,200-1,800 per tower in foundation costs across typical projects.

Yes. Aluminum transmission towers (6061-T6 alloy) achieve 50-70 kg/m compared to 200-800 kg/m for steel equivalents—a 60-75% weight reduction. However, aluminum costs 200-300% more per ton. Weight savings become economical primarily for helicopter installation in mountainous terrain where transportation costs exceed the material premium, or in highly corrosive coastal environments

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.