100m Steel Tower for Broadcast & Telecom

2025-12-20

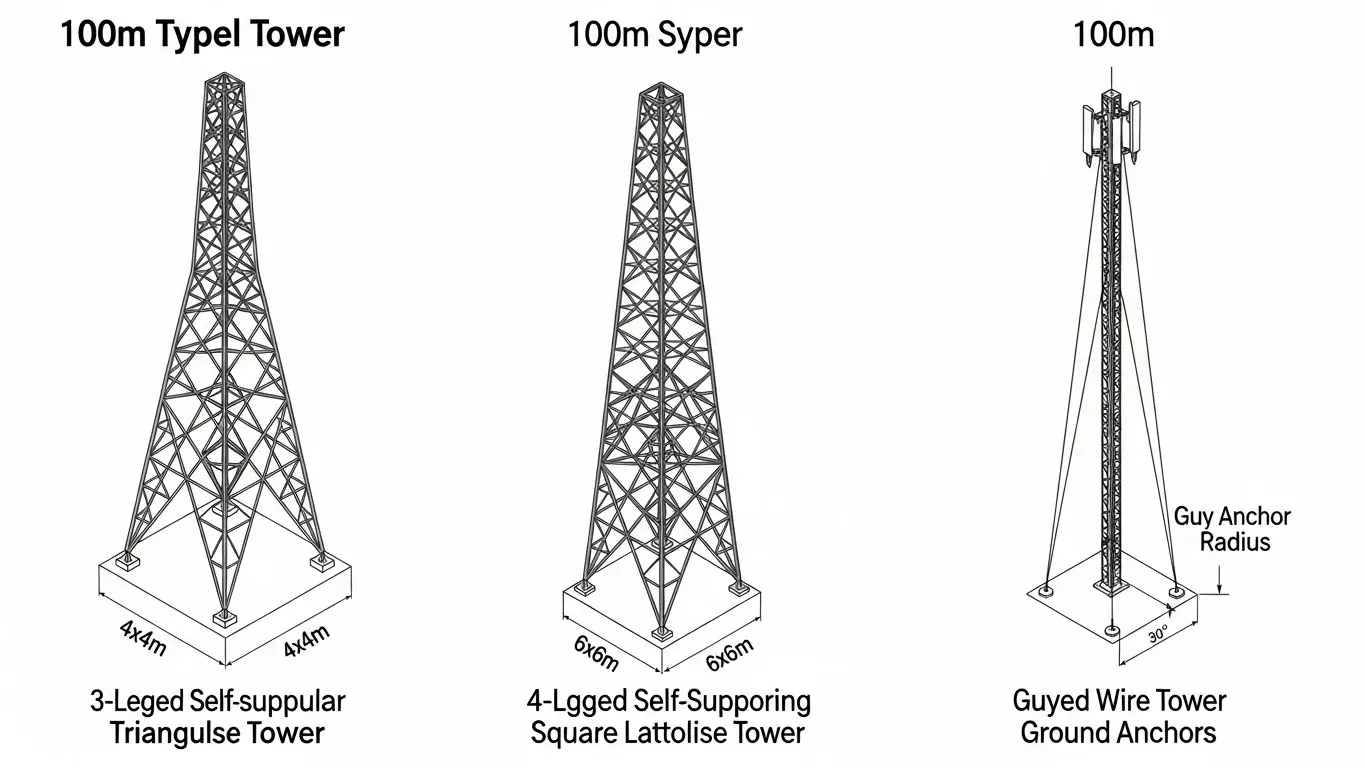

A 100m steel tower is a lattice structure manufactured from Q235B or Q345B structural steel, available in 3-leg or 4-leg self-supporting designs or guyed wire configurations. These towers deliver a 35.6 km broadcast coverage radius, serve populations up to 600,000, and cost $1,118-$1,680 per ton depending on the configuration and steel grade selected.

| Specification | 3-Leg Self-Supporting | 4-Leg Self-Supporting | Guyed Wire |

|---|---|---|---|

| Height | 100m | 100m | 100m |

| Total Weight | 45-60 tons | 60-80 tons | 25-40 tons |

| Foundation Size | 4×4m to 6×6m | 6×6m to 10×10m | 1.5×1.5m (plus guy anchors) |

| Material Grade | Q235B/Q345B | Q235B/Q345B | Q235B/Q345B |

| Wind Resistance | 30-50 m/s | 30-50 m/s | 30-50 m/s |

| Ice Loading | 8-12mm | 8-12mm | 8-12mm |

| Design Life | 50 years | 50 years | 50 years |

| Price per Ton | $1,280-$1,480 | $1,380-$1,680 | $1,118-$1,280 |

The choice between tower types depends on your site conditions, budget, and application requirements. Let's break down exactly what you need to know.

What Is a 100m Steel Tower?

100m steel towers are lattice communication structures built from hot-dip galvanized angle steel or tubular steel members. These towers support broadcast antennas, telecommunication equipment, and radio transmission systems at heights where signal propagation reaches maximum efficiency.

At X.Y. Tower, our 17 years of manufacturing experience has taught us that tower selection starts with understanding your coverage requirements. A 100m tower serves three primary markets:

- TV Broadcast Stations: 40% of applications, requiring UHF/VHF antenna arrays

- Telecommunication Networks: 45% of installations, mounting cellular base stations (4G/5G)

- Radio Broadcasting: 15% of deployments, particularly FM transmission in rural areas

The lattice design reduces wind load by 60-70% compared to solid monopole structures. This translates to lower foundation costs and faster installation times.

Coverage Area Calculation for 100m Towers

Your broadcast coverage depends on a simple physics formula. Here's how it works.

Coverage radius = √(2 × Earth radius × Tower height)

For a 100m tower: √(2 × 6,370,000m × 100m) = 35,637 meters (35.6 km)

This provides a theoretical coverage area of approximately 4,000 square kilometers. In our export projects across Africa and Southeast Asia, we've seen this translate to serving 400,000-600,000 people at population densities of 1,000 per km².

But terrain matters. Hills, buildings, and forests create shadowing effects that reduce this theoretical maximum. That's why broadcast engineers typically plan for 80-85% of the calculated coverage in real installations.

| Tower Height | Coverage Radius | Coverage Area | Population Served (1000/km²) |

|---|---|---|---|

| 70m | 29.8 km | 2,790 km² | 280,000 |

| 80m | 31.9 km | 3,200 km² | 320,000 |

| 100m | 35.6 km | 4,000 km² | 400,000 |

| 120m | 39.1 km | 4,800 km² | 480,000 |

| 150m | 43.7 km | 6,000 km² | 600,000 |

For projects requiring extended coverage, consider reviewing our guide on rooftop telecom structures which explains how elevation gain from building-mounted towers adds 15-20 km to your effective radius.

Types of 100m Steel Towers: Which One You Need

Self-Supporting Towers (3-Leg vs 4-Leg)

Self-supporting towers stand independently without guy wires. We manufacture both configurations at our 33,000 square meter facility in Chengdu.

3-Leg Towers use a triangular footprint measuring 4×4m to 6×6m. These work well for urban sites where land is expensive. The triangular geometry distributes loads efficiently through three main leg members, typically using L90×90×8mm to L150×150×12mm angle steel sections.

Total weight runs 45-60 tons for a 100m height. Our engineering team designs these with Q235B steel (yield strength 235 MPa) for standard wind zones or Q345B steel (yield strength 345 MPa) for coastal regions and high-wind areas.

4-Leg Towers require larger foundations (6×6m to 10×10m) but handle heavier antenna loads. The square configuration provides superior torsional rigidity—critical when mounting multiple heavy panel antennas on different faces.

Weight increases to 60-80 tons. The additional steel costs 15-20% more, but you gain 30-40% more antenna mounting capacity.

At our galvanizing factory, we process all tower sections with hot-dip galvanization per ASTM A123 standards. Coating thickness reaches 86-120 microns, ensuring the 50-year design life even in corrosive environments.

Guyed Wire Towers

Guyed towers cut steel weight by 40-50% compared to self-supporting designs. The guy wires (typically 7×19 strand galvanized steel cables) transfer lateral loads to ground anchors positioned 30-50 meters from the tower base.

This makes them ideal for rural broadcast sites where land cost isn't a constraint. The main tower section weighs only 25-40 tons, reducing material costs from $1,680/ton to $1,118/ton.

The tradeoff? You need clear land extending 50 meters in three directions (for 3-point guy systems). Guy anchors require their own foundation work—usually 2×2×2 meter concrete blocks weighing 12-15 tons each.

We've exported guyed towers to over 20 countries since 2017. They perform exceptionally well in Southeast Asian markets where land availability isn't restricted.

Decision Matrix: Which Type Fits Your Project

Choose 3-leg self-supporting when:

- Urban sites with limited land (less than 15×15m available)

- Budget allows $77,000-$115,000 total project cost

- Need moderate antenna loading (8-12 panels)

- Want simplified foundation work

Choose 4-leg self-supporting when:

- Heavy antenna loading required (15-25 panels)

- Torsional rigidity is critical (microwave dishes + cellular panels)

- Budget supports $92,000-$135,000 investment

- Local codes require higher safety factors

Choose guyed wire when:

- Rural sites with 100×100m or larger footprint

- Budget-conscious project ($50,000-$85,000 total)

- Simple antenna configuration (single broadcast array)

- Soil conditions allow deep guy anchors

Understanding your pricing structure helps with budget planning. Our comprehensive breakdown of transmission tower price per ton explains how material costs, fabrication, and galvanization affect your final investment.

100m Steel Tower Specifications & Standards

Material Properties: Q235B vs Q345B Steel

Your steel grade selection determines structural performance and cost. Here's what 40,000 tons of annual production has taught us.

| Property | Q235B Steel | Q345B Steel |

|---|---|---|

| Yield Strength | 235 MPa | 345 MPa |

| Tensile Strength | 370-500 MPa | 470-630 MPa |

| Carbon Content | 0.12-0.20% | 0.12-0.20% |

| Best Applications | Standard wind zones (< 40 m/s) | High wind zones, seismic areas |

| Cost Difference | Baseline | +15-20% |

| Recommended Use | Inland installations | Coastal, typhoon regions |

Q235B serves 80% of installations perfectly. It's the workhorse steel for broadcast towers in normal environmental conditions. Our automated production lines punch, cut, and form Q235B angle steel with minimal waste.

Q345B becomes necessary in three scenarios:

- Wind zones exceeding 40 m/s basic wind speed

- Seismic regions rated 7+ on the intensity scale

- Heavy loading (20+ panel antennas plus microwave equipment)

The 47% higher yield strength allows our design team to reduce member sizes while maintaining the same structural capacity. This partially offsets the material premium.

Manufacturing Standards Compliance

Our 180-person team manufactures to three primary standard systems:

ANSI/TIA-222-G (North American Standard)

- Governs structural design for antenna-supporting structures

- Specifies wind load calculations (Section 2.6)

- Ice loading requirements (Section 2.7)

- Foundation design criteria (Section 3.1)

We use TowerCAD software to verify ANSI/TIA-222-G compliance for all export projects to the Americas and Africa.

GB/T2694-2010 (Chinese National Standard)

- Covers technical specifications for steel lattice towers

- Material requirements aligned with GB/T700 and GB/T1591

- Welding quality per GB/T50661

- Hot-dip galvanization per GB/T13912

ASTM Standards (International Reference)

- ASTM A123: Hot-dip galvanization specifications

- ASTM A36: Structural steel requirements (equivalent to Q235B)

- ASTM A572 Grade 50: High-strength steel (equivalent to Q345B)

ISO 9001 certification at our facility ensures consistent quality control throughout the 10 automated production lines. Every tower section undergoes ultrasonic testing for weld integrity before leaving our factory.

For projects requiring specialized tower configurations, explore our tension tower and terminal tower solutions designed for transmission line applications.

100m Steel Tower Price: Complete Cost Breakdown

Let's talk real numbers. Price transparency matters.

Price Per Ton Analysis

Steel tower pricing follows a tiered structure:

Guyed Wire Towers: $1,118-$1,280/ton

- Lowest material consumption (25-40 tons)

- Simpler fabrication (fewer connections)

- Standard Q235B steel adequate

- Less complex galvanization

3-Leg Self-Supporting: $1,280-$1,480/ton

- Moderate complexity (45-60 tons)

- More connection points

- Mix of Q235B and Q345B possible

- Standard galvanization process

4-Leg Self-Supporting: $1,380-$1,680/ton

- Highest fabrication complexity (60-80 tons)

- Maximum connection density

- Often requires Q345B for optimization

- Extended galvanization time

These per-ton rates include raw steel, CNC cutting and punching, welding, quality testing, and hot-dip galvanization at our dedicated HDG factory.

Complete Project Cost

Here's what the total investment looks like:

| Component | Guyed Wire | 3-Leg Self-Supporting | 4-Leg Self-Supporting |

|---|---|---|---|

| Steel Structure | $28,000-$51,000 | $58,000-$89,000 | $83,000-$134,000 |

| Foundation Work | $6,000-$12,000 | $10,000-$18,000 | $14,000-$25,000 |

| Guy Anchors (3 sets) | $8,000-$12,000 | N/A | N/A |

| Installation Labor | $8,000-$15,000 | $12,000-$20,000 | $15,000-$25,000 |

| Transportation | $3,000-$6,000 | $5,000-$8,000 | $6,000-$10,000 |

| Total Project | $53,000-$96,000 | $85,000-$135,000 | $118,000-$194,000 |

Foundation costs vary by soil conditions. Rocky substrates require less excavation but more blasting. Soft clay soils need deeper piles or larger pad footings.

Transportation depends on distance from our Chengdu factory to the destination port. Container shipping to Africa runs $4,000-$7,000 for a full 40' high-cube container. Southeast Asian shipments cost $2,500-$5,000.

Cost-Saving Strategies

Three approaches reduce total project expense:

1. Choose Guyed Over Self-Supporting (where land permits) Saves 35-45% on steel structure costs. Land availability is the only limiting factor.

2. Optimize Steel Grade Selection Use Q235B for all members except high-stress locations. Our engineering team can perform mixed-grade designs that use Q345B only where structural analysis demands it. This cuts material costs by 8-12% versus all-Q345B designs.

3. Bulk Ordering for Multi-Site Projects Orders exceeding 200 tons qualify for volume pricing (5-8% discount). We've supplied multi-tower projects across Africa where buyers saved $15,000-$30,000 per site through consolidated procurement.

Similar cost optimization applies to specialized installations. Our analysis of suspension tower design for transmission lines shows how choosing the right tower type for your specific application reduces total lifecycle costs.

Installation Requirements & Timeline

Foundation Design Requirements

Foundation work consumes 20-30% of total project time. Here's what you're building.

Self-Supporting Tower Foundations:

Typical design calls for reinforced concrete pads or pile caps:

- 3-Leg: 4×4×1.2m pad (19 cubic meters concrete) with 12-16 anchor bolts per leg

- 4-Leg: 6×6×1.5m pad (54 cubic meters concrete) with 16-20 anchor bolts per leg

Excavation depth reaches 3-5 meters depending on frost line and soil bearing capacity. Concrete grade typically M30 (equivalent to C25/30 or 4,000 PSI).

Our structural drawings specify anchor bolt patterns, embed depths, and base plate details. Foundation bolts use Grade 8.8 or higher (equivalent to ASTM A490).

Guyed Tower Foundations:

Central tower base: 1.5×1.5×2.0m concrete pad (4.5 cubic meters)

Guy anchors (3 required): Each anchor consists of:

- 2×2×2m concrete block (8 cubic meters)

- 3-4 deadman anchors or helical anchors

- Guy attachment hardware

Guy anchor positions form a triangle with 30-50m radius from tower center. Actual spacing depends on guy wire angle (typically 45-60 degrees from horizontal).

Installation Process & Timeline

Week 1-3: Foundation Work

- Excavation and formwork

- Reinforcement steel placement

- Concrete pouring and curing

- Anchor bolt alignment (tolerance ±2mm)

Week 4-7: Tower Erection Crane selection depends on tower weight and height. For 100m installations, you need:

- Mobile crane: 50-80 ton capacity minimum

- Boom length: 60m minimum reach

- Crew size: 8-12 workers (rigging team + installation crew)

Tower sections arrive pre-assembled in 8-12 meter lengths. Our factory trial-assembles all sections before shipment to verify bolt hole alignment.

Assembly sequence:

- Base section installation (2-3 days)

- Progressive section stacking (5-8 days for 10-12 sections)

- Guy wire installation (guyed towers only, 2-3 days)

- Platform and ladder installation (2-3 days)

- Lightning protection system (1-2 days)

Week 8-10: Antenna Mounting & Testing

- Antenna bracket installation

- Equipment mounting

- Cable routing and grounding

- RF testing and commissioning

Total timeline: 10-12 weeks from site mobilization to final commissioning.

Weather delays can extend this by 2-4 weeks in monsoon regions. We recommend scheduling installation during dry seasons.

Maintenance Requirements for 50-Year Service Life

Hot-dip galvanization provides exceptional corrosion protection, but maintenance still matters. Here's the schedule we recommend to our international clients.

| Maintenance Task | Frequency | Duration | Typical Cost | |---|---|---| | Visual Inspection | Annual | 4-6 hours | $500-$1,000 | | Bolt Retightening | Every 2-3 years | 2-3 days | $2,000-$4,000 | | Galvanization Touch-Up | Every 5-7 years | 3-5 days | $3,000-$6,000 | | Guy Wire Tension Check | Annual (guyed towers) | 2-4 hours | $400-$800 | | Structural Analysis | Every 10 years | Engineering study | $5,000-$10,000 |

Critical Inspection Points:

- Connection Bolts: Grade 8.8 bolts can loosen due to thermal cycling and wind-induced vibration. Check torque values match design specifications (typically 400-600 N⋅m for M20-M24 bolts).

- Galvanization Integrity: Look for white rust (zinc oxide) or red rust (base steel exposure). Minor zinc oxidation is normal. Exposed steel requires immediate touch-up with zinc-rich primer.

- Guy Wire Tension: Proper tension maintains structural stability. Undertensioned guys reduce tower capacity by 15-25%. We provide load charts specifying required tension values.

- Foundation Settlement: Monitor anchor bolt projection heights. Differential settlement exceeding 10mm requires structural evaluation.

Proper maintenance extends the 50-year design life to 60-70 years in practice. Our towers exported to Africa in 2017-2018 show zero structural degradation in their 7-8 year service life so far.

Buying Guide: How to Choose Your 100m Steel Tower

Six critical decisions determine project success.

Step 1: Calculate Your Coverage Requirements

Start with the population you need to serve. Use the coverage formula:

Required tower height = (Desired radius)² ÷ (2 × 6,370,000m)

For 30 km radius: (30,000m)² ÷ (2 × 6,370,000m) = 71 meters

For 40 km radius: (40,000m)² ÷ (2 × 6,370,000m) = 126 meters

A 100m tower delivers the 35.6 km radius sweet spot for most regional broadcast applications.

Step 2: Evaluate Site Conditions

Soil bearing capacity determines foundation design and cost. Request geotechnical investigation with:

- Standard Penetration Test (SPT) values

- Soil classification (clay, sand, rock)

- Water table depth

- Seismic zone classification

Wind zone matters enormously. ANSI/TIA-222-G defines wind zones A through D:

- Zone A: 40 m/s basic wind speed

- Zone B: 45 m/s

- Zone C: 50 m/s

- Zone D: 60 m/s (hurricane/typhoon regions)

Higher wind zones require heavier structures or Q345B steel.

Step 3: Select Tower Type

Use the decision matrix from earlier:

- Limited land → Self-supporting

- Ample land + budget focus → Guyed wire

- Heavy loading → 4-leg self-supporting

- Standard loading → 3-leg self-supporting

Step 4: Choose Material Grade

Q235B works for 80% of applications:

- Wind zones A and B

- Seismic zones 1-6

- Standard antenna loading

Q345B required for:

- Wind zones C and D

- Seismic zones 7+

- Heavy microwave dish installations (2.4m+ diameter)

Step 5: Verify Standards Compliance

Match your project location to the appropriate standard:

- Americas, Africa: ANSI/TIA-222-G

- Europe: EN 1993-3-1 (Eurocode 3)

- China, Southeast Asia: GB/T2694-2010

- International projects: Request dual compliance

At X.Y. Tower, our design software handles all three standard systems. We deliver certified structural calculations with every tower shipment.

Step 6: Supplier Qualification

Check these minimum qualifications:

- ✅ ISO 9001 certification

- ✅ Own galvanizing facility (ensures quality control)

- ✅ Minimum 5 years export experience

- ✅ Structural engineering department (not just fabrication)

- ✅ Reference projects in similar climate zones

Our 180-person team includes 12 structural engineers with ANSI/TIA-222-G training. We've shipped to 20+ countries across 5 continents since 2017.

Factory visits matter. International buyers are welcome at our Chengdu facility to inspect production equipment, galvanizing lines, and quality control processes.

Frequently Asked Questions

A 100m steel tower provides a 35.6 km coverage radius, covering approximately 4,000 square kilometers. This can serve 400,000-600,000 people at typical population densities of 1,000 per square kilometer. Actual coverage depends on terrain obstacles, antenna height above tower top, and transmission power. Line-of-sight limitations reduce this theoretical maximum by 15-20% in hilly regions.

Complete 100m steel tower projects cost $53,000-$194,000 depending on configuration. Guyed wire towers run $53,000-$96,000 total (lightest option). 3-leg self-supporting towers cost $85,000-$135,000. 4-leg self-supporting designs reach $118,000-$194,000. These prices include steel structure ($1,118-$1,680/ton), foundation work, installation labor, and transportation. Location, soil conditions, and steel grade choice significantly impact final pricing.

3-leg towers weigh 45-60 tons, use triangular 4×4m to 6×6m foundations, and cost 15-20% less than 4-leg designs. They're ideal for moderate antenna loading (8-12 panels). 4-leg towers weigh 60-80 tons, require square 6×6m to 10×10m foundations, and handle heavy loading (15-25 panels). The 4-leg configuration provides 30-40% better torsional rigidity for multiple-face antenna mounting.

Q235B steel (235 MPa yield strength) serves 80% of applications—standard wind zones under 40 m/s and seismic zones 1-6. Q345B steel (345 MPa yield strength) is necessary for high-wind zones (40+ m/s), coastal typhoon regions, seismic zones 7+, and heavy microwave installations. Q345B costs 15-20% more but allows optimized designs with smaller member sizes in high-stress applications.

Complete installation requires 10-12 weeks from site mobilization to commissioning. Foundation work takes 3 weeks (excavation, concrete pouring, curing). Tower erection requires 3-4 weeks with a 50-80 ton crane and 8-12 person crew. Antenna mounting and testing add 2-3 weeks. Weather delays can extend timelines by 2-4 weeks in monsoon climates. Schedule installation during dry seasons for best results.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.