80m Telecommunication Tower: Complete Specification and Cost Guide

2025-12-23

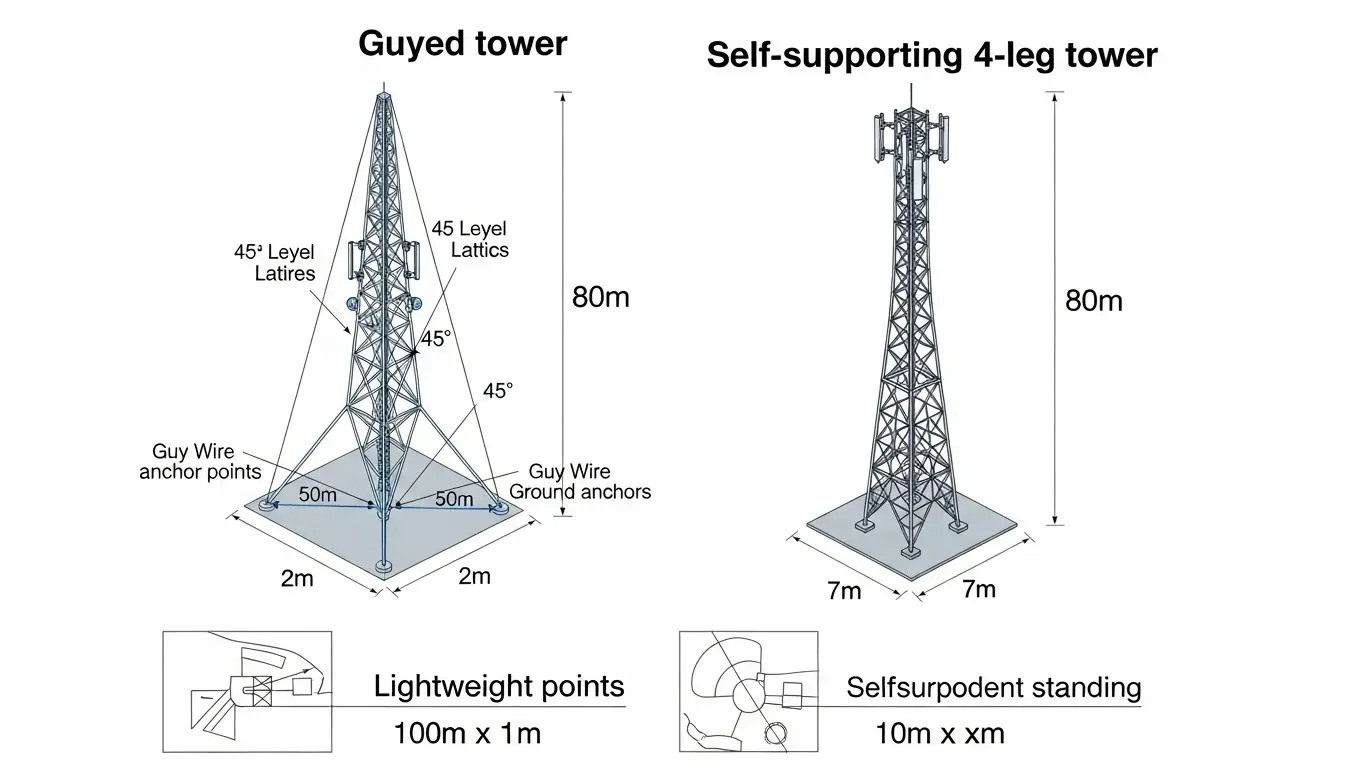

An 80-meter telecommunication tower is a steel lattice structure designed to support cellular (4G/5G), microwave, and broadcast antennas at 262-foot height. Available in guyed or self-supporting configurations using Q235B or Q345B steel with hot-dip galvanization, these towers deliver 30-50 year service life. Guyed towers cost $80,000-$120,000 and use 40-60% less steel than self-supporting designs ($140,000-$180,000), making them more economical for rural deployments covering 5-15km radius.

At this height, you need to understand the structural differences. The choice between tower types affects your total project budget by $60,000-$100,000.

Why 80m is a Critical Height

80 meters sits at the sweet spot for macro cell coverage. You get better signal propagation than 50-60m towers without the exponential costs of 100m+ structures.

Most operators deploy 80m towers for:

- 4G/5G macro base stations in suburban areas

- Microwave backhaul links spanning 20-40km

- FM broadcast stations covering 50-80km radius

- Multi-operator collocation sites

We've manufactured 80m towers for projects across Africa and Southeast Asia since 2008. The height works particularly well in flat terrain where you need extended coverage without excessive infrastructure costs.

Guyed Towers at 80m: The Economical Choice

Guyed towers dominate at 80m height for good reason: they use significantly less steel while maintaining structural integrity through guy wire support.

How Guyed Towers Work

The tower itself is a lightweight lattice structure stabilized by 3-4 levels of guy wires anchored 48-64 meters from the base. Each guy level connects to ground anchors using high-tensile steel cables, creating a stable support system that resists wind loads up to 150 mph.

Key Specifications:

| Specification | Typical Range |

|---|---|

| Base face width | 1.5-2.5m |

| Top face width | 0.8-1.2m |

| Guy anchor radius | 48-64m (60-80% of height) |

| Steel weight | 15-25 tons |

| Antenna payload | 3-6 tons |

| Cost range | $80,000-$120,000 |

| Land required | 100m x 100m minimum |

Advantages:

- Cost savings: 40-60% less steel than self-supporting towers

- Higher wind resistance: Guy wires provide superior stability

- Easier transportation: Lighter sections fit standard containers

- Lower foundation costs: Smaller base requires less concrete

Limitations:

You need substantial land (minimum 10,000 square meters). Guy anchors occupy space in a 50-65m radius around the tower. This makes guyed designs impractical for urban sites or areas with restricted access.

Our engineering team at X.Y. Tower designs guyed towers using ANSI/TIA-222 standards, calculating precise guy tension requirements for your specific wind zone.

Self-Supporting 80m Towers: Urban Solution

Self-supporting lattice towers stand independently without guy wires, using heavier steel construction to resist loads through the structure itself.

These towers come in 3-leg (triangular) or 4-leg (square) configurations. At our facility in Chengdu, we produce both types with telecommunication tower services tailored to project requirements.

3-Leg vs 4-Leg Comparison:

| Specification | 3-Leg Tower | 4-Leg Tower |

|---|---|---|

| Base width | 6-8m | 5-7m |

| Steel weight | 35-45 tons | 40-55 tons |

| Land footprint | 64-100 sq.m | 49-64 sq.m |

| Antenna mounting | 3 faces | 4 faces |

| Cost | $140,000-$160,000 | $160,000-$180,000 |

When to Choose Self-Supporting:

- Urban locations where land costs exceed structural savings

- Rooftop installations where guy anchors are impossible

- Sites near roads or buildings where guy wires create access issues

- Multi-operator collocation requiring maximum mounting space

The heavier construction costs more upfront but eliminates ongoing guy wire maintenance. We galvanize all self-supporting towers in our dedicated HDG factory in Guanghan, ensuring 86+ micron zinc coating thickness for 30-50 year corrosion resistance.

Technical Specifications You Must Know

Material Standards:

We manufacture 80m towers using Q235B or Q345B structural steel per GB/T2694-2018 standard. Q345B provides 345 MPa yield strength - 40% stronger than Q235B - which matters for extreme wind zones or heavy antenna loads.

Our 40,000-ton annual production capacity includes complete material traceability. Every steel batch undergoes chemical composition analysis and tensile testing before fabrication.

Wind Load Design:

Per TIA-222 Revision I (effective January 2024), 80m towers must withstand:

- Basic wind speed: 115-150 mph (3-second gust)

- Ice thickness: 0-25mm radial (zone-dependent)

- Seismic loads: Per ASCE 7-22 requirements

We calculate exact wind loads using MS Tower and SAP2000 software, accounting for your specific geographic location, terrain category, and Risk Category classification.

Foundation Requirements:

Foundation costs represent 25-35% of total project budget:

Guyed Tower Foundation:

- Main base: 2.5m x 2.5m x 2.5m concrete cube

- Each guy anchor: 2m x 2m x 3m buried concrete block

- Total concrete: 40-60 cubic meters

- Foundation cost: $25,000-$35,000

Self-Supporting Foundation:

- Single base: 7m x 7m x 3m reinforced concrete

- Requires soil bearing capacity ≥150 kPa

- Total concrete: 120-180 cubic meters

- Foundation cost: $45,000-$70,000

The soil at your site determines final foundation design. Poor soil conditions can double foundation costs through requirements for deeper excavation or pile foundations.

Applications: 4G, 5G, and Microwave Deployment

80m towers excel at supporting multiple communication technologies simultaneously.

Cellular Networks (4G/5G):

At 80m height, a macro cell site covers 5-15km radius depending on terrain and frequency bands:

- 700-900 MHz (low-band 4G): 10-15km coverage

- 1800-2600 MHz (mid-band 4G/5G): 5-10km coverage

- 3300-3800 MHz (5G mid-band): 3-7km coverage

Our towers accommodate 6-12 panel antennas across 3-4 platform levels. Typical platform spacing is 6-8 meters for optimal antenna isolation.

Microwave Backhaul:

80m height enables microwave links spanning 25-45km with clear line-of-sight. We install microwave dishes (0.6-3.0m diameter) on dedicated mounts to avoid interference with cellular antennas.

For projects requiring both cellular and microwave equipment, we design platform layouts that maintain FCC/ITU separation requirements between antenna types.

Broadcasting Applications:

FM and TV stations use 80m towers to achieve 50-100km coverage radius. Broadcast antennas generate higher wind loads than cellular equipment, requiring upgraded structural calculations.

Similar to how our railway electrification towers serve critical infrastructure, 80m broadcast towers often carry emergency backup equipment and redundant power systems.

Cost Breakdown and ROI Analysis

Total Project Costs (Guyed Tower):

| Cost Component | Amount |

|---|---|

| Tower structure | $80,000-$120,000 |

| Foundation (main + anchors) | $25,000-$35,000 |

| Transportation | $8,000-$15,000 |

| Installation labor | $15,000-$25,000 |

| Total Project Cost | $128,000-$195,000 |

Total Project Costs (Self-Supporting):

| Cost Component | Amount |

|---|---|

| Tower structure | $140,000-$180,000 |

| Foundation | $45,000-$70,000 |

| Transportation | $12,000-$20,000 |

| Installation labor | $18,000-$30,000 |

| Total Project Cost | $215,000-$300,000 |

30-Year Total Cost of Ownership:

Add annual maintenance ($2,000-$4,000) and major inspections every 10 years ($8,000-$12,000):

- Guyed tower 30-year TCO: $185,000-$255,000

- Self-supporting 30-year TCO: $275,000-$365,000

Guyed towers require guy wire tension checks annually ($500-$1,000), while self-supporting towers need only bolt torque verification ($300-$600).

The $90,000-$110,000 premium for self-supporting towers makes sense when your site has limited land or when you're planning collocation revenue that generates $15,000+ annually from tenant leases.

Manufacturing and Lead Time

At X.Y. Tower's manufacturing facility, we follow a rigorous production process for 80m towers:

Production Timeline:

- Engineering design: 5-10 days

- Material procurement: 7-15 days

- Fabrication: 15-25 days

- Galvanization: 3-5 days

- Quality inspection & packing: 2-3 days

Total manufacturing lead time: 30-45 days from order confirmation.

Our 180-person team operates 10 automated production lines with 16-meter CNC bending machines and laser cutting equipment. This allows us to maintain consistent quality while meeting delivery schedules for projects across Africa, Southeast Asia, South America, and Europe.

Quality Control Process:

Every tower undergoes:

- Raw material chemical composition analysis

- Dimensional inspection at each fabrication stage

- Mechanical tensile testing (per ASTM A370)

- Hot-dip galvanization to ASTM A123 (86+ micron thickness)

- Final assembly test fitting

- Non-destructive testing of critical welds

We document all inspection results and provide material test certificates with every shipment.

Installation Requirements

80m tower installation is a specialized operation requiring proper equipment and experienced crews.

Equipment Needed:

- Mobile crane: 50-80 ton capacity

- Gin pole for self-erecting towers (alternative method)

- Concrete mixer and pump for foundation

- Specialized rigging equipment

- Fall protection systems

Installation Timeline:

- Foundation work: 5-7 days (plus 14-21 day concrete cure time)

- Tower erection: 5-10 days

- Antenna installation: 2-3 days

- Testing and commissioning: 1-2 days

Weather significantly impacts installation. Wind speeds above 25 mph halt crane operations. Plan for seasonal conditions in your region.

Our team provides detailed installation drawings and can arrange on-site supervision through our international project support network. For smaller projects, many clients successfully install using our comprehensive installation manuals and remote technical support.

Comparing 80m to Other Heights

Why Not 60m?

60-meter towers cost 25-30% less but provide 15-20% less coverage radius. The cost-per-square-kilometer covered actually favors 80m towers in most scenarios.

We manufacture 25m telecom towers for urban infill sites, but these serve different purposes than macro site 80m towers.

Why Not 100m?

100-meter towers cost 40-50% more than 80m structures. You're paying exponentially more for diminishing coverage returns. At 100m, you also trigger stricter FAA lighting requirements (adding $8,000-$15,000 in red obstruction lights and ongoing maintenance).

80m hits the optimal balance for most telecom deployments.

Maintenance and Longevity

Properly maintained 80m towers serve 30-50 years. Here's what maintenance actually involves:

Annual Inspections ($2,000-$3,000):

- Visual inspection of all structural members

- Guy wire tension measurement (guyed towers)

- Bolt torque verification

- Galvanization condition assessment

- Grounding system continuity testing

- Antenna mount security checks

10-Year Major Inspection ($10,000-$15,000):

- Detailed non-destructive testing of welds

- Guy wire replacement (if needed)

- Galvanization touch-up on worn areas

- Foundation concrete assessment

- Complete structural load analysis update

Common Issues to Watch:

- Guy wire corrosion (especially in coastal environments)

- Loose bolts from thermal cycling

- Galvanization wear at connection points

- Foundation settling in poor soil conditions

Addressing minor issues costs $500-$2,000. Ignoring them leads to $20,000+ emergency repairs.

In our 17 years of manufacturing experience, we've found that towers with proper annual maintenance easily exceed 40-year service life. Several of our early 2008 installations in Africa still operate at full capacity today.

Selecting the Right Manufacturer

Your tower manufacturer matters as much as the tower type. Poor manufacturing causes structural failures, extended delays, and excessive maintenance costs.

What to Verify:

- Production capacity: Can they handle your volume? We maintain 40,000-ton annual capacity with documented delivery schedules.

- Own galvanizing facility: Third-party galvanizing adds 2-3 weeks and quality control gaps. Our integrated HDG factory ensures consistent coating thickness.

- Design software: Verify they use industry-standard tools (MS Tower, SAP2000, PLS-TOWER). Hand calculations aren't sufficient for 80m structures.

- International standards compliance: Look for ISO 9001 certification and experience with TIA-222, EN, or ASTM standards.

- Export experience: Domestic-only manufacturers often struggle with international shipping documentation and standards compliance.

Similar to how material choice matters in steel pole vs concrete pole decisions, manufacturer selection directly impacts your project success and long-term costs.

Frequently Asked Questions

Guyed towers use guy wires anchored 48-64m from the base for stability, requiring 100m x 100m land but costing $80,000-$120,000 with 40-60% less steel. Self-supporting towers stand independently with 6-8m base width, need only 64-100 square meter footprint, but cost $140,000-$180,000 due to heavier construction. Choose guyed for rural sites with available land; choose self-supporting for urban locations where land is limited.

Per TIA-222 Revision I (2024), 80m towers withstand 115-150 mph three-second gust wind speeds depending on Risk Category and geographic location. Guyed towers typically achieve higher wind resistance through guy wire stabilization. Exact wind load calculations incorporate terrain category, topographic effects, and ice accumulation based on your specific site coordinates. Most telecom installations use Risk Category II requiring 115-130 mph design wind speed.

Total installation spans 25-40 days: foundation excavation and concrete pouring takes 5-7 days, concrete curing requires 14-21 days, tower erection takes 5-10 days using 50-80 ton cranes, and antenna installation plus commissioning needs 3-5 days. Weather delays and permit approvals can extend timeline. Manufacturing lead time adds 30-45 days before installation begins. Complete project timeline from order to commissioning typically ranges 3-6 months.

80m towers accommodate multiple applications: 4G/5G cellular macro sites with 6-12 panel antennas covering 5-15km radius depending on frequency band, microwave backhaul dishes (0.6-3.0m diameter) for 25-45km point-to-point links, FM broadcast antennas providing 50-100km coverage, and multi-operator collocation with proper antenna separation. Typical antenna payload capacity is 3-8 tons across 3-6 platform levels spaced 6-8 meters apart for optimal RF isolation.

Properly maintained 80m towers deliver 30-50 year service life. Hot-dip galvanized steel (86+ micron zinc coating per ASTM A123) prevents corrosion, while annual inspections ($2,000-$3,000) identify issues early. Major inspections every 10 years ($10,000-$15,000) include guy wire tension checks, bolt torque verification, and galvanization touch-up. Coastal environments may reduce lifespan to 25-35 years without additional protective measures. Our towers manufactured in 2008 remain fully operational today across multiple continents.

Ready to Specify Your 80m Tower?

Selecting the right 80m tower configuration requires analyzing your specific site conditions, budget constraints, and long-term operational plans.

We've manufactured 80m towers for telecom operators, broadcasters, and infrastructure providers across 20+ countries since 2008. Our communication tower portfolio includes successful installations from dense urban environments to remote rural locations.

Every project starts with understanding your requirements: coverage objectives, site constraints, wind zone classification, and budget parameters. From there, our engineering team designs a solution that optimizes structural performance and total cost of ownership.

Contact X.Y. Tower for:

- Detailed technical specifications for your site

- Delivered cost quotation including shipping

- Complete engineering drawings and calculations

- Manufacturing timeline and delivery schedule

We maintain stock of standard components and can expedite critical projects when needed. Our team responds to technical inquiries within 24 hours with actionable recommendations.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.