Emergency Communication Tower for Disaster Relief: Complete Buyer's Guide

2025-12-24

Emergency communication towers deploy in 15 minutes to 6 hours and support 1,000-2,000+ concurrent users within a 2-5 mile coverage radius. These portable cellular systems—including COW (Cell on Wheels), SatCOLT, and lattice towers—operate 24-48 hours on integrated generators and meet ANSI/TIA-222 structural standards for disaster response when fixed networks fail.

The difference between saving lives and losing them often comes down to one thing: connectivity.

When Hurricane Ike hit Louisiana in 2008, the Port of South Louisiana had portable emergency towers ready. They restored communications in 30 minutes. Coordination improved dramatically. Lives were saved.

Most disaster zones don't have that luxury. Power lines fall. Cell towers collapse. Fixed infrastructure fails exactly when you need it most.

That's where emergency communication towers prove their value. But here's what procurement managers and emergency coordinators get wrong—they think all portable towers are the same.

They're not.

In our 17 years manufacturing steel towers for disaster relief applications across Africa, Southeast Asia, and South America, we've seen agencies make costly mistakes. They pick towers that can't handle the terrain. Or systems that take too long to deploy. Or equipment that runs out of power during critical operations.

This guide fixes that. You'll get specific deployment times, real coverage numbers, and the technical specs that separate functional systems from failures.

What Is an Emergency Communication Tower?

An emergency communication tower is portable cellular infrastructure designed for rapid deployment when permanent networks are damaged or overwhelmed. Unlike fixed telecommunications towers that require months to construct and permit, emergency towers transport on trailers or trucks and become operational within hours.

These systems serve three critical functions:

First, they restore basic voice and data connectivity in disaster zones where infrastructure has been destroyed. When hurricanes, earthquakes, or floods knock out cell towers, portable units fill the gap immediately.

Second, they augment existing networks during mass events where user density exceeds normal capacity. Major sporting events, concerts, and political rallies can overload fixed towers—portable systems handle the surge.

Third, they provide communications in remote locations where permanent infrastructure doesn't exist. Construction sites, military operations, and rural emergency response all rely on these mobile solutions.

The core components include a telescopic or lattice mast structure (typically 8-150 feet), cellular antennas and transceivers, backhaul connectivity (fiber, microwave, or satellite), integrated power systems (generators or batteries), and weatherproof equipment enclosures rated to IP55 standards.

Types of Emergency Communication Towers

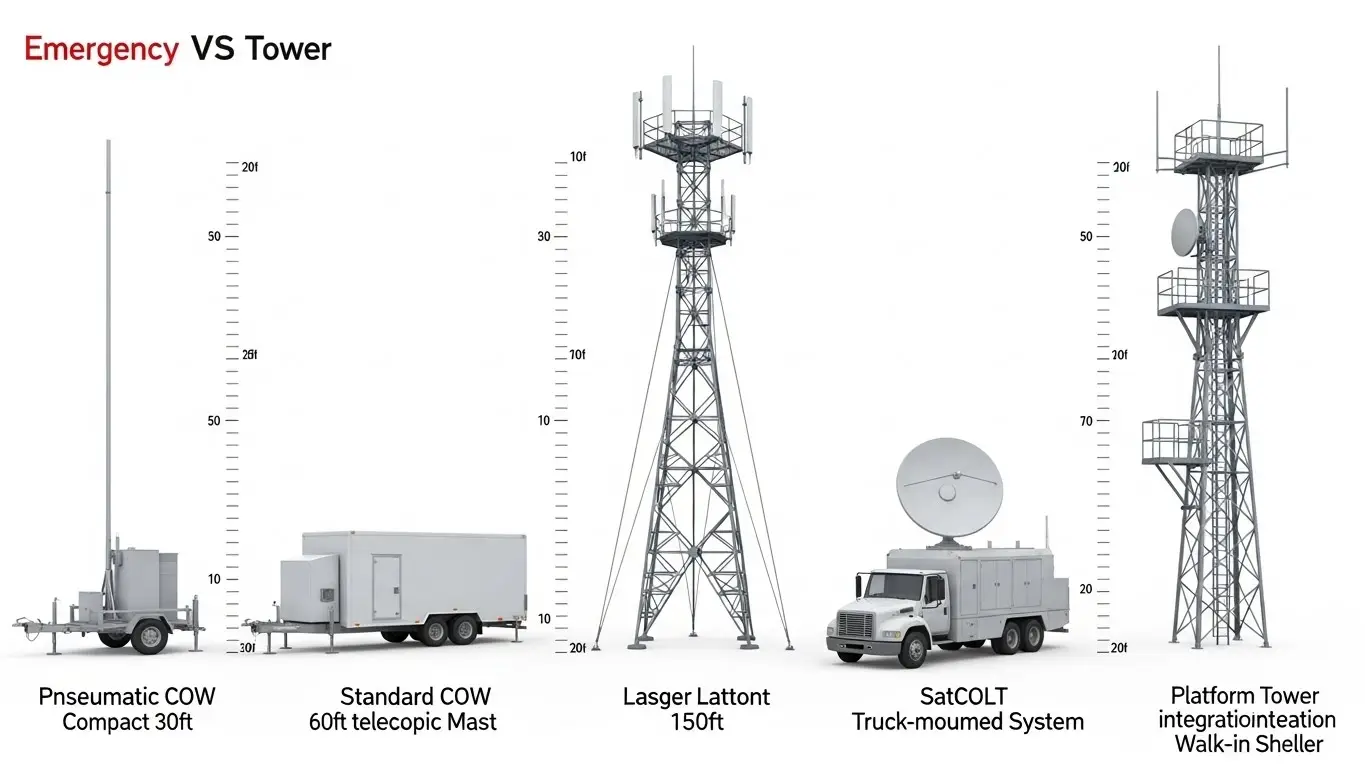

Five primary tower types serve different deployment scenarios. Choosing the wrong type costs you time, coverage, or both.

Cell on Wheels (COW)

COW units mount on trailers with telescopic masts extending 20-70 feet. Two-person crews deploy standard systems in 15-30 minutes. The S6 Mini-COW from manufacturers like Aluma Tower can be towed by a ½-ton truck, making it ideal for tight access routes.

Typical configurations include 60-foot pneumatic masts, integrated equipment shelters with HVAC, 9.5-25kW diesel generators, and space for 4-9 equipment racks. These units support 1,000-1,500 concurrent users with fiber or microwave backhaul.

We design telecommunication tower systems using ANSI/TIA-222-G-2 standard software, ensuring COW platforms meet structural requirements for 90-150 mph wind loads depending on the deployment zone.

Satellite Cell on Light Truck (SatCOLT)

SatCOLTs mount directly on truck chassis instead of trailers, improving mobility in rough terrain. The critical advantage: integrated satellite backhaul eliminates dependence on existing infrastructure.

FirstNet operates over 180 dedicated SatCOLT units nationwide with a 14-hour delivery objective following emergency requests. These truck-mounted systems access remote disaster zones where fiber and microwave links don't exist.

Trade-off: satellite backhaul typically provides lower bandwidth (1-5 Mbps) compared to microwave or fiber systems (1-10 Gbps), limiting simultaneous user capacity to 500-1,000 depending on data usage patterns.

Lattice Mobile Towers

Lattice structures reach heights up to 150 feet, dramatically expanding coverage radius to 4-5 miles in flat terrain. The triangular or square steel framework distributes wind loads across guy wires or self-supporting bases.

Deployment time extends to 4-6 hours with 2-4 person crews, but the expanded coverage often eliminates the need for multiple smaller units. These towers handle heavier equipment loads, supporting multiple cellular carriers and frequencies on a single structure.

Our manufacturing facility produces lattice components using Q355B structural steel with hot-dip galvanizing to ASTM A123 specifications, ensuring 30+ year operational life even in corrosive coastal environments.

Pneumatic Mast Systems

Self-erecting pneumatic masts extend 8-15 meters (26-49 feet) using compressed air systems with staged locking mechanisms. Single operators can deploy these units in 15-20 minutes, making them the fastest emergency response option.

The compact design suits urban disaster zones where space constraints prevent larger COW deployments. However, the lower height limits coverage to 2-3 mile radius and user capacity to 800-1,200 concurrent connections.

Platform Towers with Integrated Shelters

Walk-in equipment shelters mounted on drop-deck trailers provide both tower infrastructure and protected workspace for equipment and personnel. These comprehensive solutions include Faraday Cage technology for EMI protection—critical when electromagnetic interference threatens sensitive communications equipment.

Setup requires 3-6 hours but delivers command center functionality with multiple workstations, charging stations, and large exterior displays for briefings. Perfect for extended deployments lasting weeks or months rather than days.

Similar to how we engineer railway electrification towers for reliable long-term service, these shelter-integrated systems prioritize operational endurance over rapid deployment.

Emergency Tower Deployment Timeline

Real deployment speed depends on crew training, site conditions, and system complexity. Here's what actually happens in the field:

| System Type | Minimum Setup | Average Setup | Crew Size | Transport Method | Site Prep |

|---|---|---|---|---|---|

| Pneumatic COW | 15 minutes | 20-30 minutes | 1 person | ½-ton truck | Minimal—level ground |

| Standard COW | 20 minutes | 2-3 hours | 2 persons | ¾-ton to 1-ton truck | Level pad, guy wire space |

| Large COW/TOW | 2 hours | 4-6 hours | 2-4 persons | 1.5-ton truck or semi | Concrete pad, guy anchors |

| SatCOLT | 30 minutes | 2-4 hours | 2 persons | 4x4 truck | Minimal—rough terrain OK |

| Lattice Tower | 4 hours | 6-8 hours | 3-4 persons | Semi trailer | Guy anchor installation |

The 15-minute deployment claims you see in marketing materials? That's trained crews with pre-positioned equipment in ideal conditions. Reality adds 2-3x that time once you factor in transportation logistics and actual disaster zone constraints.

FirstNet's 14-hour delivery objective recognizes this gap between specification and field reality. Emergency requests trigger deployment, but getting equipment to remote disaster zones, navigating damaged infrastructure, and establishing secure sites takes time.

Technical Specifications That Matter

You need specific numbers to make informed decisions. Generic "high capacity" claims won't help when you're allocating emergency response budgets.

Coverage & Capacity

Coverage radius varies from 2 to 5 miles based on three factors: tower height, terrain topology, and antenna configuration.

A 60-foot telescopic COW provides 3-4 mile radius in flat agricultural areas but only 1.5-2 miles in dense urban environments with building interference. Add 30-50% more coverage by increasing height to 100+ feet with lattice towers.

User capacity specifications usually cite peak concurrent connections—but what you actually get depends on data usage patterns. A tower rated for 2,000 users supports that number for voice calls and basic messaging. Heavy video streaming or data transfers drop that to 500-800 users before network performance degrades.

Aggregate throughput of 1+ Gbps sounds impressive until 1,500 users simultaneously stream video. Each 1080p stream consumes 5-8 Mbps, maxing out capacity with just 125-200 streams.

Power & Operational Duration

Diesel generators dominate emergency deployments due to proven reliability and fuel availability in disaster zones. Standard configurations include:

- Small COW: 9.5kW generator, 25-40 gallon tank, 24-30 hour runtime

- Medium COW: 15-20kW generator, 50-75 gallon tank, 36-48 hour runtime

- Large TOW: 25kW+ generator, 100+ gallon tank, 48-72 hour runtime

Runtime calculations assume 60-80% average generator load. Peak traffic periods drain fuel faster—plan on 20-30% shorter runtime during maximum usage.

Extended deployments beyond 72 hours require on-site refueling logistics or grid connection with automatic transfer switches. Solar hybrid systems reduce generator runtime by 30-50% in sunny climates, cutting fuel costs and resupply requirements.

Our 40,000-ton annual production capacity allows us to customize power configurations based on specific deployment scenarios—from Arctic conditions requiring cold-weather diesel systems to tropical zones where solar-diesel hybrids maximize efficiency.

Backhaul Connectivity

Backhaul links the portable tower to the broader telecommunications network. Three options exist:

Fiber optic provides 1-10 Gbps capacity with sub-5ms latency but requires existing fiber infrastructure within a few hundred meters. Fastest deployment when fiber is available, but that's rare in disaster zones.

Microwave links deliver 1-10 Gbps throughput across 1-10 mile distances using point-to-point millimeter-wave systems. E-band frequencies (70-80 GHz) provide gigabit speeds but require line-of-sight and careful alignment. Setup adds 1-2 hours to deployment time.

Satellite backhaul works anywhere but limits bandwidth to 1-5 Mbps for standard systems (50-500 Mbps for advanced Ka-band terminals). Latency of 500-700ms affects voice quality and real-time applications. Use satellite as backup when fiber and microwave aren't viable.

Standards & Certifications for Emergency Towers

Emergency communication towers must meet structural, electrical, and safety standards despite their temporary status. Agencies that skip these requirements face liability issues when equipment fails during critical operations.

Structural Standards

ANSI/TIA-222 is the structural standard for antenna-supporting structures in North America. Current revision TIA-222-G-2 (adopted in 2016) specifies wind loading, deflection limits, and structural analysis requirements.

All towers must calculate wind loads based on three-second gust wind speeds specific to the deployment region. Most portable towers design to 90-110 mph sustained winds, with some heavy-duty systems rated to 150 mph for hurricane-prone zones.

The standard defines three structure classes:

- Class I: Optional services (residential wireless, amateur radio)

- Class II: Essential services with network redundancy (most commercial cellular)

- Class III: Essential services with zero redundancy (emergency services)

Emergency communication towers typically qualify as Class II due to network redundancy—if one tower fails, neighboring sites maintain coverage. However, towers supporting E911 or first responder networks with zero redundancy must meet Class III requirements with increased safety factors.

Design Wind Loads

EIA/TIA specifications mandate design wind speeds for every U.S. county. Towers can specify higher wind ratings than minimum requirements—critical for deployments in hurricane zones or mountainous terrain with accelerated wind flows.

Wind pressure calculations use pounds per square foot (psf) or miles per hour (mph) measurements. A 110 mph wind creates approximately 30 psf pressure on flat surfaces—that's 300 pounds per square foot on antenna arrays, which is why mast strength and guy wire tension matter.

Just as we engineer steel versus concrete poles for different wind and ice loading scenarios, emergency tower selection must account for maximum expected wind conditions in the deployment zone.

Electrical & Safety Standards

IP55 rating is minimum weatherproofing for outdoor equipment enclosures, protecting against dust ingress and water jets from any direction. IP65 or IP67 ratings provide additional protection for submersible installations or extreme weather deployments.

Temperature ranges for electronic equipment should span -30°C to +50°C (-22°F to 122°F) with integrated HVAC systems maintaining internal temperatures. Thermal failures cause more equipment losses than water damage in most disaster scenarios.

Grounding and lightning protection follows NFPA 780 and IEEE standards. Towers require copper grounding conductors sized per the maximum lightning current expected (typically 8 AWG minimum), connected to driven ground rods or ground grids achieving less than 10 ohms resistance to earth.

FirstNet Compliance

Public safety agencies using FirstNet networks require equipment compatible with Band 14 (700 MHz) and specific encryption protocols. FirstNet Response Operations Group (ROG) maintains over 180 dedicated deployable assets with guaranteed interoperability.

FirstNet pioneered tower-to-core network encryption using open industry standards—the first nationwide network with comprehensive security. Emergency towers connecting to FirstNet must support these encryption protocols to maintain security certification.

Real-World Emergency Deployments

Numbers tell you what's possible. Case studies show what actually works.

Hurricane Response: Port of South Louisiana

When Hurricane Ike destroyed cell infrastructure in 2008, the Port of South Louisiana deployed PTM-100 portable towers in 30 minutes. Communications restored, evacuation coordination improved, and recovery operations accelerated by an estimated 40% compared to neighboring areas without pre-positioned equipment.

Key success factors: Pre-positioned equipment, trained deployment crews, and integration with existing emergency response protocols. The port continues using these systems today for both emergency response and temporary network augmentation during maintenance operations.

Wildfire Communication: FirstNet Flying COWs

FirstNet's three Flying COW units (cells on wings) reach altitudes up to 400 feet using tethered aerostat systems. Mountain rescue missions and wildfire response benefit from elevated antennas that overcome terrain obstacles blocking traditional ground-based towers.

California wildfire response in 2020-2021 demonstrated the value of aerial systems. Standard COW units couldn't establish line-of-sight links across ridgelines, forcing deployment of multiple ground towers. A single Flying COW covered 3x the area with better signal penetration into canyons and valleys.

Remote Construction: Mining Operations

Remote mining sites in Australia and South America rely on emergency tower technology for permanent communications where fixed infrastructure is economically unjustifiable. A 80-meter telecommunication tower provides permanent service, but 3-5 year construction timelines don't work for projects with 18-24 month lifespans.

Lattice mobile towers on semi-permanent foundations serve as intermediate solutions—deployed in 1-2 days, operational for years, and recoverable when operations complete. These installations often evolve into permanent infrastructure as mining operations expand.

Deployment Process: Step-by-Step

Successful emergency tower deployment follows a proven sequence. Skipping steps causes delays or failures during critical operations.

Step 1: Emergency Assessment (30-60 minutes)

Emergency coordinators evaluate:

- Coverage area requirements based on affected population and response team dispersion

- Expected user volume and data requirements

- Available backhaul options (satellite, microwave, temporary fiber)

- Terrain constraints and access routes

- Power availability and fuel logistics

- Deployment duration estimate

This assessment determines tower type selection. A 500-person evacuation center needs different capacity than a 5,000-person disaster zone with multiple response agencies.

Step 2: Tower Selection & Dispatch (1-4 hours)

Match tower specifications to assessed requirements:

- Coverage radius determines minimum tower height

- User capacity drives equipment rack configuration

- Terrain accessibility selects trailer vs. truck mounting

- Duration influences power system sizing (generator capacity and fuel storage)

FirstNet's 14-hour delivery objective includes this selection phase plus transportation logistics. Commercial deployments without pre-positioned assets often extend to 24-48 hours from emergency request to on-site arrival.

Step 3: Transportation & Site Access (2-12 hours)

Moving multi-ton trailer systems through disaster zones poses unique challenges. Damaged roads, collapsed bridges, and debris fields block primary routes. Site selection must balance optimal coverage with transportation accessibility.

Advance reconnaissance teams identify viable routes and pre-position fuel if extended off-road transit is required. Satellite imagery updated post-disaster helps plan routes, but ground truth usually reveals unexpected obstacles.

Step 4: Site Preparation (30 minutes - 3 hours)

Minimum requirements include:

- Level ground for trailer stabilization (outriggers require solid bearing surface)

- Guy wire anchor points for guyed towers (80% of tower height distance from base)

- Clear vertical space free of overhead power lines and obstacles

- Security perimeter establishment

- Fuel storage and refueling access

Rocky or uneven terrain requires ballast blocks or engineered foundation systems, adding 2-6 hours to deployment timelines. Soft soil conditions may need reinforcement to prevent settlement under wind loading.

Step 5: Tower Erection (15 minutes - 6 hours)

Fastest deployments use self-erecting pneumatic masts. Connect compressed air, activate hydraulic systems, and the mast extends to full height with automatic stage locking.

Lattice towers require component assembly, guy wire installation and tensioning, and mast raising using gin poles or mobile cranes. This phase determines total deployment time—rushed erection creates safety hazards and structural instabilities.

Our engineering team designs custom tower configurations accounting for local wind loads, ice accumulation, and seismic activity. A 25-meter telecom tower in a low-wind region uses lighter structural members than an identical height tower rated for hurricane conditions, reducing both cost and weight.

Step 6: Equipment Installation (1-3 hours)

Antenna mounting, transceiver installation, coaxial cable routing, and backhaul system setup follow tower erection. Proper cable management prevents damage from wind-induced movement—cables must have appropriate service loops and weatherproof connectors.

Backhaul alignment takes longest for microwave systems. Point-to-point links require precise angular alignment (±0.5 degrees typical), which involves iterative adjustment while monitoring signal strength. Budget 30-90 minutes for proper microwave alignment depending on link distance and available alignment tools.

Step 7: System Integration & Testing (30 minutes - 2 hours)

Power systems activate first—generator startup, automatic transfer switch verification, and load testing confirm stable electrical service. Electronic equipment follows: transceivers, network core equipment, and routing systems.

Network integration involves authentication with carrier core networks, frequency coordination to avoid interference with existing sites, and base station parameter configuration for coverage optimization.

Step 8: Activation & Handoff (15-30 minutes)

Final system checks include:

- Coverage testing using drive or walk tests with field measurement equipment

- User registration testing confirming devices can connect and authenticate

- Voice call quality testing

- Data throughput testing under load

- Emergency shutdown and restart procedures verification

Operations team receives training on basic troubleshooting, refueling procedures, and maintenance requirements before the deployment crew departs.

Cost Analysis: Purchase vs. Rental

Emergency tower economics depend on deployment frequency, duration, and maintenance capabilities.

Purchase Costs

| System Type | Purchase Price Range | Typical Configuration |

|---|---|---|

| Mini-COW | $75,000 - $150,000 | 30-40ft mast, 10kW gen, basic shelter |

| Standard COW | $200,000 - $400,000 | 60ft mast, 20kW gen, full shelter, HVAC |

| Large COW/TOW | $500,000 - $800,000 | 100ft+ mast, 25kW gen, walk-in shelter |

| SatCOLT | $300,000 - $600,000 | Truck-mounted, satellite backhaul, ruggedized |

| Lattice Mobile Tower | $150,000 - $400,000 | 150ft height, modular design, heavy load capacity |

These prices include basic equipment but exclude:

- Cellular transceivers and radio equipment ($50,000-$200,000)

- Advanced features (solar systems, enhanced EMI protection)

- Transportation to deployment sites

- Installation services

- Spare parts inventory

Rental Economics

Monthly rental rates average $4,000 for standard COW systems, with variations based on:

- Equipment specifications and capability

- Rental duration (longer terms reduce daily rates)

- Included services (transportation, setup, maintenance)

- Generator fuel inclusion or exclusion

Event organizers and agencies with infrequent emergency needs (less than 3-4 deployments annually) benefit from rental models. Purchase becomes economical when deployment frequency exceeds 5-6 times per year or when equipment serves dual purposes (emergency response plus planned events or maintenance backups).

Total Deployment Costs

Single emergency deployment costs include:

Transportation: $2,000-$10,000 depending on distance and required vehicles. Remote disaster zones requiring helicopter transport can reach $20,000-$50,000 for airlift operations.

Setup Labor: $1,500-$5,000 for professional deployment crews (2-4 technicians for 4-24 hours including travel time).

Fuel: $200-$1,000 per week of operation based on generator size and runtime. Extended deployments requiring repeated refueling logistics add $500-$2,000 in fuel transport costs.

Backhaul Connectivity:

- Fiber: $0 if existing infrastructure used, $5,000-$20,000 for temporary fiber installation

- Microwave: $500-$2,000 for link rental, $0 after purchase

- Satellite: $1,000-$5,000 per month for bandwidth costs

Site Services: $500-$3,000 for security, site preparation, and teardown.

Total deployment costs of $10,000-$50,000 per event align with industry experience. Agencies budget $25,000-$35,000 for standard 7-14 day emergency deployments with professional setup services.

ROI for Emergency Management Agencies

Five-year total cost of ownership calculations:

Ownership Model:

- Initial purchase: $300,000 (standard COW system)

- Annual maintenance: $15,000-$25,000

- Storage and insurance: $5,000-$10,000 annually

- Deployment costs (5x annually): $50,000 total

- Five-year TCO: $500,000-$575,000

Rental Model:

- Per-deployment rental: $4,000-$6,000

- Setup services: $3,000-$5,000 per deployment

- Deployments (5x annually): $35,000-$55,000 per year

- Five-year TCO: $175,000-$275,000

The crossover point occurs at 8-12 deployments annually depending on system specifications and included services. Agencies with higher deployment frequency or requiring immediate response capability benefit from ownership despite higher upfront costs.

Choosing the Right Emergency Tower

Assessment criteria determine optimal system selection.

Coverage Requirements

Calculate required coverage radius using population density and geographic constraints. Urban deployments with 2-mile radius coverage need towers only 30-50 feet tall due to concentrated population. Rural disaster zones with 5-mile radius requirements need 80-120 foot towers for equivalent population coverage.

Terrain impacts effective coverage significantly. Add 30-50% height in mountainous regions to overcome line-of-sight obstacles. Coastal areas with flat terrain maximize coverage efficiency—a 60-foot tower reaches 4+ miles in ideal conditions.

User Capacity Planning

Peak simultaneous users drive capacity requirements. Hurricane evacuation centers might serve 2,000-3,000 people, but realistic simultaneous usage rarely exceeds 30-40% during normal operations (600-1,200 concurrent users).

Emergency conditions change usage patterns. Immediately following disasters, 60-80% of affected populations attempt simultaneous connectivity as they contact family members and emergency services. Plan for peak capacity 1.5-2x normal projections.

Deployment Frequency & Duration

Infrequent Use (1-3x yearly): Rental models optimize economics and eliminate maintenance burden. Partner with established providers offering rapid deployment services.

Moderate Use (4-8x yearly): Evaluate lease-to-own programs or purchase with third-party maintenance contracts. Equipment familiarity improves as your teams gain deployment experience.

Frequent Use (9+ yearly): Purchase justifies the investment. Develop internal maintenance capabilities and cross-train operations staff for basic troubleshooting.

Deployment duration influences system selection. Events lasting less than 72 hours suit lightweight pneumatic COW systems with minimal site preparation. Extended deployments beyond two weeks benefit from lattice towers with walk-in shelters providing better crew working conditions.

Budget Constraints

Total program costs include:

- Equipment acquisition or rental

- Transportation and logistics

- Training and certification

- Spare parts inventory

- Storage facilities

- Annual maintenance and inspections

Agencies allocate 15-25% of initial equipment costs annually for full lifecycle support. A $300,000 COW system requires $45,000-$75,000 yearly operating budget for proper maintenance, training, and readiness.

Integration with Existing Networks

Compatibility with current emergency response communications determines interoperability. FirstNet agencies prioritize Band 14 compatible equipment. Commercial carrier partnerships require specific frequency bands and authentication protocols.

Camouflage telecommunications towers demonstrate how specialized requirements drive tower design decisions. Emergency systems similarly need customization based on operational requirements rather than generic specifications.

Future Technology Trends

Emergency communication tower technology continues advancing. Here's what's changing and what procurement decisions should account for.

5G-Advanced Capabilities

Massive MIMO antenna arrays with 64T64R configurations deliver 3-5x capacity improvements over 4G systems. Dynamic spectrum sharing (DSS) allows simultaneous 4G/5G operation on the same frequencies, maximizing spectrum efficiency during upgrades.

Emergency towers deploying in 2025 should specify 5G capability even if initial deployment uses 4G networks. Hardware upgrade costs exceed $50,000-$100,000 when retrofitting 4G-only systems, versus $10,000-$20,000 incremental costs for initial 5G-ready procurement.

AI-Driven Network Optimization

Machine learning algorithms predict traffic patterns and automatically adjust network parameters for optimal performance. AI optimization reduces manual configuration time from hours to minutes and improves network efficiency by 20-30% under varying load conditions.

These systems learn from deployment data—the more deployments, the better the optimization. Agencies with frequent use cases see faster ROI than organizations with occasional emergencies.

Autonomous Deployment Systems

Robotics and automation reduce deployment crew requirements. Prototype systems demonstrate single-operator deployment of towers requiring 2-4 person crews with current technology. Full autonomous deployment remains 5-10 years away, but semi-automated systems reducing crew size by 30-50% are available now.

Enhanced Battery Technology

Lithium-ion battery storage systems provide silent, emission-free operation for 8-24 hours without generator runtime. Hybrid battery-generator configurations use batteries for overnight operations, running generators only during high-demand daytime periods.

This reduces fuel consumption by 40-60% and extends deployment duration between refueling. Battery technology costs continue declining—systems uneconomical in 2020 reached cost parity with diesel-only configurations in 2024 for many use cases.

Low Earth Orbit Satellite Integration

Starlink, OneWeb, and other LEO constellations deliver 50-200 Mbps satellite bandwidth with 20-40ms latency—dramatically better than traditional geostationary satellite systems. These links support 1,000+ concurrent users with acceptable voice quality and data speeds.

LEO backhaul eliminates infrastructure dependencies for emergency deployments in any location globally. Current costs of $500-$2,000 monthly for business service will decline as competition increases and production scales.

Frequently Asked Questions

Deployment ranges from 15 minutes to 6 hours depending on system type and site conditions. Small COW units with trained 2-person crews become operational in 15-30 minutes on prepared sites. Larger systems with integrated shelters require 4-6 hours for complete setup including backhaul integration and network testing.

Coverage radius spans 2 to 5 miles based on tower height, terrain, and antenna configuration. Standard 60-foot COW towers provide 3-4 mile radius in flat terrain but only 1.5-2 miles in urban areas with building interference. Lattice towers reaching 100-150 feet extend coverage to 4-5 miles even in challenging terrain.

Most systems operate 24-48 hours on integrated diesel generators with 50-100 gallon fuel capacity. Extended deployments use on-site refueling, grid connection via automatic transfer switches, or hybrid solar-diesel systems for continuous operation. Runtime varies with equipment load—peak usage periods reduce operational duration by 20-30%.

COW units mount on trailers and require existing backhaul infrastructure (fiber or microwave). SatCOLT systems mount on trucks with integrated satellite connectivity, operating in areas with zero existing infrastructure. SatCOLTs offer superior mobility for rough terrain but provide lower bandwidth (1-5 Mbps) compared to fiber or microwave backhaul (1-10 Gbps).

Total deployment costs range from $10,000 to $50,000 per event including transportation, setup, fuel, and teardown. Monthly rental rates average $4,000 for standard COW systems. Purchase prices span $75,000 for Mini-COW units to $800,000 for large Tower on Wheels systems. Operating costs include fuel ($200-$1,000 weekly), maintenance ($15,000-$25,000 annually), and storage ($5,000-$10,000 yearly).

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.