Rooftop Telecom Structure: Low Profile Design Guide

2025-12-20

A rooftop telecom structure is a steel antenna mounting system installed on building rooftops, typically ranging from 3 to 30 meters in height with low-profile designs under 9 meters. These structures weigh between 200-800 kg and support 3-6 antenna panels for 4G/5G networks. They cost 30-50% less than ground-based towers by eliminating land acquisition and reducing foundation requirements to non-penetrating ballast systems weighing 1,500-3,000 kg.

Your building needs wireless coverage. You can't buy land for a traditional tower. You need something that works fast, costs less, and doesn't turn your rooftop into an eyesore.

That's exactly what rooftop telecom structures solve.

What Makes a Rooftop Structure "Low Profile"?

Low profile means keeping the structure under 9 meters tall. Standard rooftop towers can reach 30 meters, but that's often unnecessary in urban areas where buildings already provide elevation.

We've manufactured rooftop structures for clients across Southeast Asia and Africa since 2017. The most requested specification? Heights between 3-6 meters. Why? Because procurement managers want adequate coverage without triggering complex aviation regulations or property owner pushback.

Here's the breakdown:

- Minimal profile: 3-6 meters (best for dense urban areas)

- Moderate profile: 6-9 meters (suburban and industrial zones)

- Extended low-profile: 9-12 meters (specific coverage gaps)

The visual impact matters. A 6-meter structure on a 20-meter building adds just 30% to the total height. A 30-meter ground tower? That's a 30-meter visual statement.

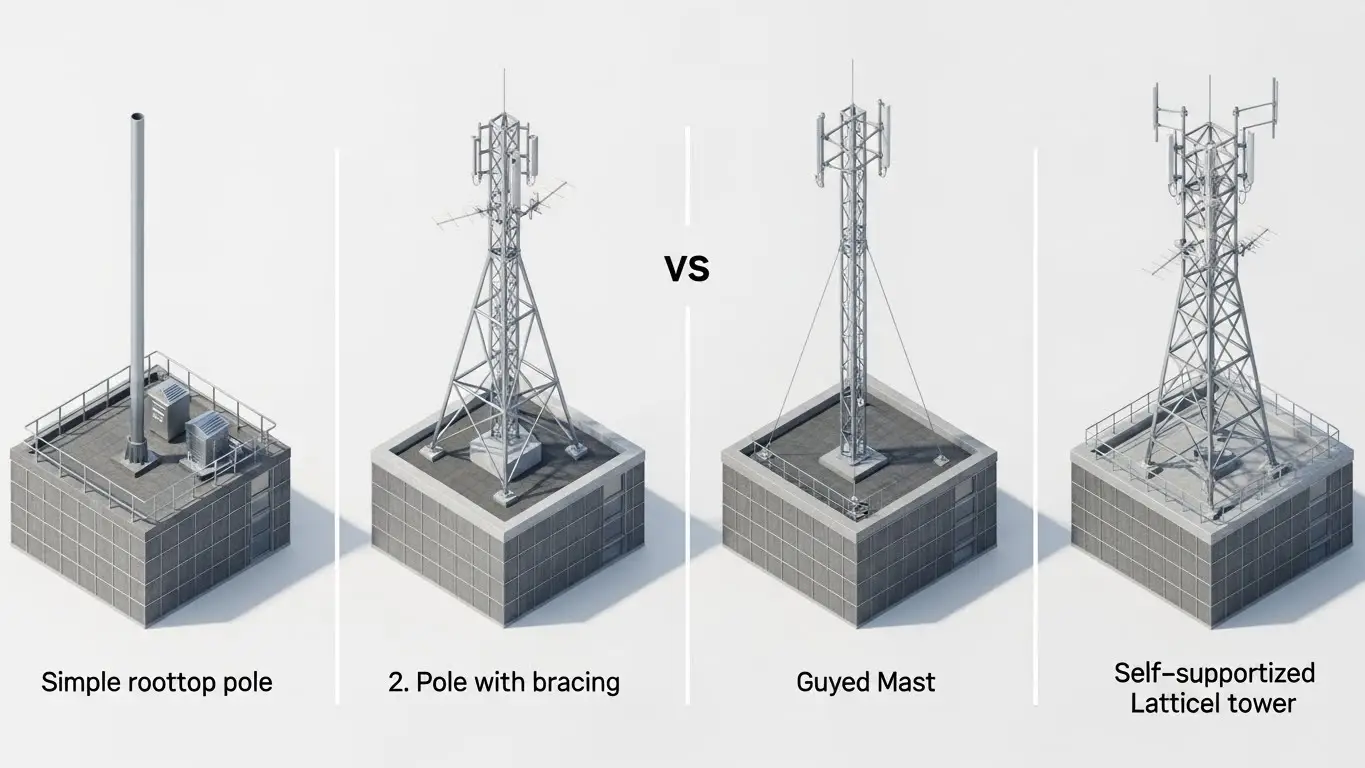

Types of Rooftop Telecom Structures

Not all rooftop structures look the same. Your building type, roof load capacity, and coverage needs determine which design works.

| Structure Type | Height Range | Weight | Antenna Capacity | Installation | Best Application |

|---|---|---|---|---|---|

| Rooftop Pole | 3-9m | 200-400 kg | 3-4 panels | 1-2 days | Urban infill, light loads |

| Pole with Bracing | 6-12m | 350-600 kg | 4-5 panels | 2-3 days | High wind areas |

| Guyed Mast | 6-15m | 300-500 kg | 4-6 panels | 2-4 days | Taller structures, tension support |

| Self-Supporting Tower | 9-21m | 500-800 kg | 5-6 panels | 3-5 days | Heavy antenna loads |

| Low-Profile Monopole | 3-9m | 250-450 kg | 3-5 panels | 1-3 days | Aesthetic-sensitive locations |

Rooftop poles are single tubes. Simple. Lightweight. Perfect when you need basic coverage without structural complexity. At our 40,000-ton capacity facility in Sichuan, these represent 40% of our rooftop orders.

Poles with bracing add lateral support arms extending from the main mast. These handle higher wind loads and heavier antennas. Use them in coastal areas or when you're mounting six 60-kg panels instead of three.

Guyed masts use tension cables (guy wires) anchored at multiple roof points. They're lighter than self-supporting towers but reach greater heights. The trade-off? You need more roof space for guy wire anchor points.

Self-supporting towers are triangular or square lattice structures. They're the workhorses for heavy equipment loads—multiple operators sharing the same structure, microwave dishes, and full 5G massive MIMO arrays.

Low Profile Structure Specifications

Numbers matter when you're specifying a rooftop structure. Here's what our engineering team uses when designing for customers:

| Height Category | Structure Weight | Foundation Type | Wind Load | Antenna Support | Service Life |

|---|---|---|---|---|---|

| 3-6m (Minimal) | 200-350 kg | Non-penetrating ballast | 30 m/s | 3-4 panels (180-240 kg) | 50 years |

| 6-9m (Moderate) | 350-600 kg | Ballast or anchored | 30 m/s | 4-5 panels (240-300 kg) | 50 years |

| 9-12m (Extended) | 600-800 kg | Anchored with reinforcement | 35 m/s | 5-6 panels (300-360 kg) | 50 years |

We manufacture these using Q355B steel (equivalent to ASTM A572 Grade 50). Hot-dip galvanizing at our dedicated facility in Guanghan provides 80-100 micron zinc coating thickness—that's roughly double what you'd get from electroplating.

The antenna capacity numbers assume standard 60-kg panels. Modern 5G MIMO antennas run heavier—sometimes 100-120 kg each. Your structural engineer needs the actual equipment weights, not assumptions.

TIA-222 Compliance for Rooftop Structures

TIA-222 is the standard that matters. Specifically, TIA-222-I (effective January 2024) replaced TIA-222-H (2018). If you're designing structures now, you're working with Revision I.

The key change for rooftop structures? Rooftop wind speed-up factor (Ks). Wind accelerates over building edges. TIA-222-I requires you to calculate this acceleration and apply higher wind loads to rooftop structures compared to ground-level towers at the same geographic location.

Here's what structural engineers evaluate:

Risk Category: Most commercial rooftop installations fall into Category II (standard occupancy). Emergency communication towers might require Category III design with 1.15x load factors.

Exposure Category: Urban rooftops typically use Exposure B or C. Exposure B assumes buildings and obstacles surrounding the site. Exposure C applies to open terrain or water surfaces.

Topographic Category: Flat roofs in flat terrain? Category 1. Rooftop on a hillside? You might need Category 3 or 4 calculations accounting for terrain-induced wind speed-up.

The result? Under TIA-222-I, member axial forces (internal stresses in steel components) increased 22-37% compared to TIA-222-G calculations for identical towers. That means heavier steel sections or reduced antenna capacity if you're upgrading an older design.

Our telecommunication tower services include TIA-222-I compliant design using ANSI/TIA-222-G-2 software, ensuring your structure meets current standards before fabrication.

Building Structural Assessment Requirements

Your rooftop can't automatically support a telecom structure. Here's the evaluation process:

Step 1: Verify Roof Load Capacity Most commercial buildings support 1.5-3.0 kPa (150-300 kg/m²) live load. Your structure concentrates load at specific points. A structural engineer calculates whether the roof deck and supporting beams handle these point loads.

Step 2: Calculate Vertical Loads Add up everything:

- Structure weight (200-800 kg)

- Antennas and radios (180-600 kg)

- Ice accumulation if applicable (varies by climate)

- Ballast blocks if using non-penetrating base (1,500-3,000 kg)

Step 3: Assess Lateral Loads Wind doesn't just push down. It pushes sideways. The structure must resist:

- Wind pressure on structure and antennas

- Seismic loads (if applicable)

- Combined load cases per TIA-222-I

Step 4: Check Overturning Stability Will wind tip the structure over? For non-penetrating systems, ballast weight must exceed overturning moment. For anchored systems, anchors must resist uplift forces—sometimes exceeding 5,000 kg per anchor point.

Step 5: Verify Deflection Limits Antennas need to point in specific directions. If your tower deflects more than 0.5 degrees under wind load, signal performance degrades. The structural analysis must prove deflections stay within limits.

This is where property owners get nervous. They worry about roof damage. That's why our emergency communication tower installations typically use non-penetrating ballast systems—no roof penetrations means no waterproofing concerns.

Why Choose Low Profile Design?

You save money. That's the simple answer. Here's the detailed breakdown:

Regulatory Advantages Most jurisdictions require FAA/aviation authority review for structures exceeding certain heights—often 60 feet (18.3m). A low-profile rooftop structure on a 20-meter building reaches 29 meters total. That's usually under the threshold.

Fewer regulatory hurdles mean faster approvals. One of our clients in Kenya reduced their permitting timeline from 8 months to 6 weeks by switching from a 30-meter ground tower to a 9-meter rooftop structure on an existing warehouse.

Structural Load Reduction Shorter structures mean lower wind loads. Wind pressure increases exponentially with height. A 9-meter rooftop structure experiences roughly 40% less wind force than a 30-meter structure at the same location.

Lower wind loads mean:

- Lighter steel sections

- Smaller foundation requirements

- Reduced structural costs

- Easier crane access for installation

Visual Impact Property owners care about aesthetics. A 6-meter structure on a rooftop blends with building mechanical equipment. A 30-meter tower dominates the skyline.

For urban deployments where community opposition can delay or kill projects, low-profile designs face significantly less pushback. Some of our camouflage telecom tower clients combine low-profile design with stealth antennas for near-invisible installations.

Cost Efficiency Our data from 180+ installations across 20 countries:

- Low-profile rooftop structure: $15,000-$35,000 total installed cost

- Standard rooftop tower (12-21m): $35,000-$60,000

- Equivalent ground-based tower: $80,000-$150,000+

You're eliminating land lease costs ($1,000-$5,000/month), extensive foundation work ($25,000-$50,000), and access road construction.

Installation Process and Timeline

Installation speed matters when you're racing to expand network coverage. Here's the realistic timeline:

Week 1-2: Site Survey and Assessment Structural engineer visits the site, measures roof dimensions, photographs existing conditions, obtains building plans (if available), and identifies access points for equipment delivery.

Week 3-5: Engineering and Permitting Structural calculations, tower design drawings, foundation design (ballast layout or anchor locations), permit applications, and building owner approvals.

Week 6-8: Manufacturing At our facility in Chengdu, we fabricate towers in 3-meter sections for easy transport. Hot-dip galvanizing at our Guanghan facility adds 5-7 days. Then shipping to site.

Week 9-10: Installation This is where low-profile design shines. Installation typically requires:

- Day 1: Crane mobilization, ballast/foundation installation

- Day 2-3: Tower section erection, bolting, alignment

- Day 4: Antenna mounting, cable installation

- Day 5: Testing, commissioning, site cleanup

Total active installation: 3-5 days for most low-profile structures.

Compare this to ground-based towers requiring 3-4 weeks for foundation curing alone. The speed advantage is substantial.

We recently completed a 25m telecom tower project in Tanzania—similar timeline despite the increased height because the client had pre-approved all engineering and permits.

Cost Analysis: Rooftop vs Ground-Based Towers

Let's compare real numbers. These are based on our manufacturing costs plus typical installation expenses:

| Cost Component | Low-Profile Rooftop | Standard Rooftop | Ground Tower | Savings |

|---|---|---|---|---|

| Land Lease (10 years) | $0 | $0 | $120,000-$600,000 | 100% |

| Foundation | $5,000-$8,000 | $8,000-$15,000 | $25,000-$50,000 | 70-85% |

| Structure & Galvanizing | $8,000-$20,000 | $20,000-$35,000 | $35,000-$70,000 | 60-75% |

| Installation Labor | $3,000-$7,000 | $7,000-$10,000 | $15,000-$30,000 | 65-80% |

| Crane & Equipment | $2,000-$4,000 | $3,000-$6,000 | $8,000-$15,000 | 60-75% |

| Permitting & Engineering | $3,000-$5,000 | $4,000-$8,000 | $8,000-$15,000 | 50-65% |

| Total Project Cost | $21,000-$44,000 | $42,000-$74,000 | $211,000-$780,000 | 75-95% |

The land lease line item deserves emphasis. In urban areas, 10-year land leases can exceed $500,000. That's money you simply don't spend with rooftop installations.

Return on investment? Most operators see payback within 18-24 months from subscriber revenue in newly covered areas.

Applications and Use Cases

Rooftop structures aren't one-size-fits-all. Here's where they excel:

Urban Network Densification 5G requires closer spacing between sites—sometimes every 200-500 meters in dense urban areas. Ground sites don't exist at that density. Rooftops do.

Gap-Fill Coverage That two-block area with poor signal? Often caused by building shadowing. A rooftop structure on the problem building eliminates the dead zone.

Multi-Tenant Shared Infrastructure One 9-meter rooftop structure can support three operators' equipment. Each operator pays their share of structure costs plus monthly site lease to the property owner. Everyone wins.

Private Networks Hospitals, universities, ports, and industrial facilities increasingly deploy private LTE/5G networks. Rooftop structures on their own buildings provide coverage without external site leases.

Emergency Communications When disaster knocks out ground infrastructure, rapidly deployable rooftop structures restore communications. We've supplied equipment for emergency response teams across Southeast Asia for exactly this scenario.

For larger coverage needs, our 80m telecommunication tower solutions provide macro-site coverage complementing rooftop structures for complete network architecture.

Maintenance and Service Life

Hot-dip galvanized steel structures last 50 years with minimal maintenance. Here's the schedule our engineering team recommends:

Annual Visual Inspection

- Check for loose bolts (retorque if needed)

- Inspect guy wires for tension and corrosion (if applicable)

- Verify antenna alignment

- Check cable management and grounding connections

- Inspect ballast blocks for movement

5-Year Detailed Inspection

- Ultrasonic testing of critical welds

- Coating thickness measurements

- Structural deflection measurements

- Foundation integrity assessment

- Complete bolt replacement if corrosion detected

Maintenance Costs Budget approximately $500-$1,500 annually for routine maintenance. The 5-year detailed inspection runs $2,000-$4,000 depending on structure complexity.

Compare this to ground-based towers requiring extensive foundation inspections, guy wire anchor replacements, and access road maintenance. Rooftop structures have lower lifetime maintenance costs.

Our ISO 9001 certified manufacturing process at our 33,000-square-meter facility ensures quality from raw steel through final galvanizing. Quality manufacturing means fewer maintenance headaches over 50 years of service.

Frequently Asked Questions

Low-profile rooftop structures typically range from 3-9 meters tall. Heights above 9 meters classify as standard-profile. The optimal height depends on required coverage area, building elevation, surrounding terrain, and regulatory height restrictions. Most urban deployments use 6-meter structures for optimal balance between coverage and regulatory simplicity.

Low-profile structures weigh 200-800 kg for the steel framework. Add 180-600 kg for antennas and radios. Non-penetrating ballast systems add 1,500-3,000 kg distributed across the roof. Total concentrated load typically ranges from 2,000-4,500 kg. A licensed structural engineer must verify the existing building can support these loads before installation.

Yes. All rooftop telecom structures must comply with TIA-222-I (2024) or TIA-222-H (2018) standards. These standards specify wind load calculations, structural design criteria, mounting system requirements, and safety factors. Compliance ensures structural integrity under maximum expected wind, ice, and seismic loads. Non-compliant structures risk structural failure, liability issues, and permit revocation.

Rooftop structures cost 30-50% less than equivalent ground-based towers. Average rooftop installation runs $15,000-$45,000 total. Ground towers cost $50,000-$150,000+ for structure alone, plus $120,000-$600,000 for 10-year land leases. Cost savings come from eliminated land acquisition, reduced foundation requirements, and faster installation timelines reducing labor expenses.

Most modern commercial and industrial buildings can support low-profile rooftop structures without reinforcement when properly designed. Structural engineers evaluate roof load capacity, select appropriate mounting methods (penetrating anchors or non-penetrating ballast), and verify deflection limits. Older buildings or residential structures may require reinforcement depending on structural condition and existing load capacity margins.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.