86 vs 100 Micron Galvanizing for Transmission Towers: Which Coating Thickness Do You Need?

2025-12-20

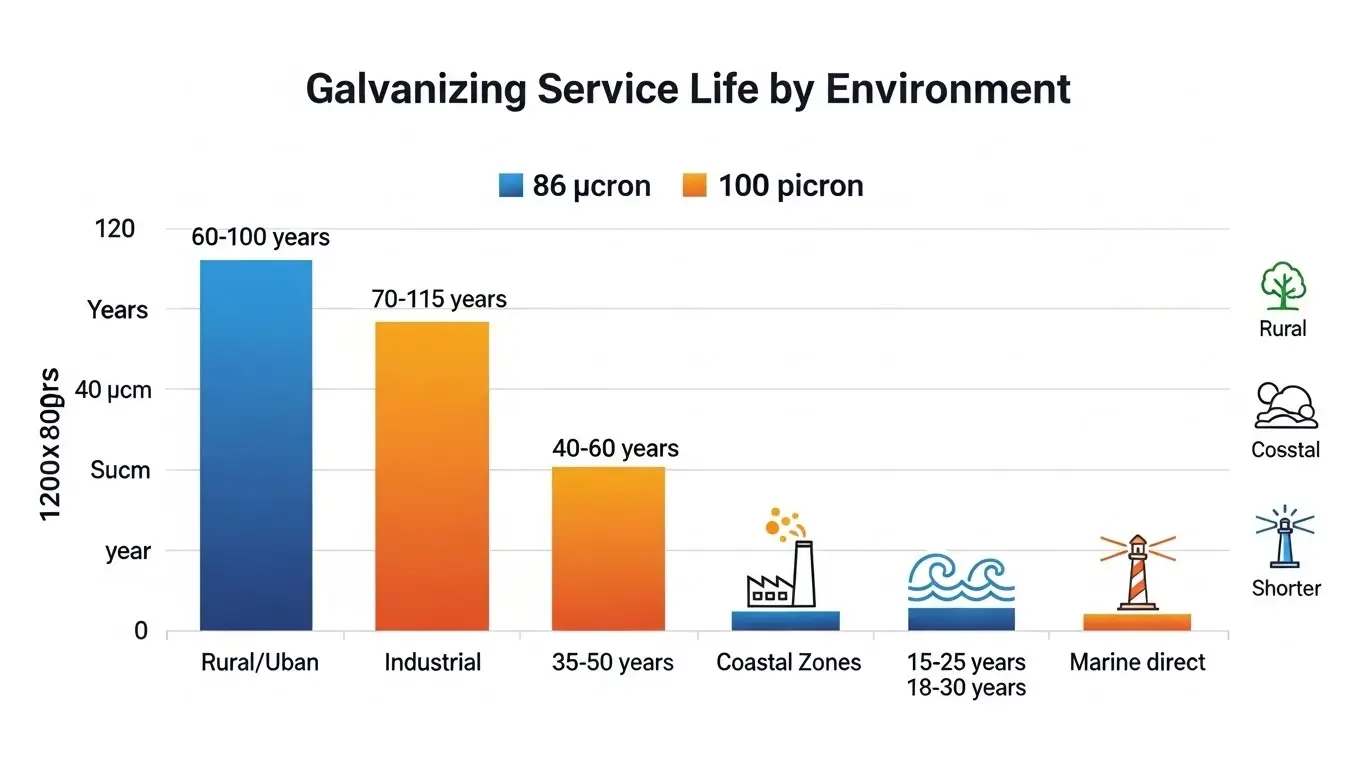

For transmission towers, 86 micron hot-dip galvanizing meets ISO 1461 and ASTM A123 minimum standards, providing 60-100 years protection in normal atmospheric conditions. 100 micron coating exceeds standards by 15%, extending service life to 70-115 years and costing 12-18% more. The thicker coating delivers better ROI in coastal, industrial, and high-pollution environments.

Both coating thicknesses work. Your choice depends on location, budget, and how long you need the structure to last.

Understanding Galvanizing Thickness Standards

International standards define minimum coating thickness for steel structures based on material thickness. ISO 1461 requires 85 micron minimum for steel sections greater than 6mm thick. ASTM A123 specifies 86 micron (2.0 oz/ft²) for structural shapes like the angle steel used in power transmission towers.

At our manufacturing facility in Chengdu, we've processed over 40,000 tons annually since 2008. Our dedicated hot-dip galvanizing factory consistently achieves 86-100 micron coating thickness through precise bath temperature control and immersion timing.

The difference between 85 and 86 micron? Metric versus imperial measurement systems. ISO uses microns (µm), while ASTM uses mils and ounces per square foot. They're essentially the same specification.

| Standard | Region | Minimum Thickness (Steel >6mm) | Typical Application |

|---|---|---|---|

| ISO 1461:2022 | International | 85 micron | Global projects |

| ASTM A123 | North America | 86 micron (2.0 oz/ft²) | US, Canada, Mexico |

| EN ISO 1461 | Europe | 85 micron | EU markets |

| GB/T 13912 | China | 80-90 micron | Domestic Chinese projects |

Why These Numbers Matter

Each micron represents one-thousandth of a millimeter. A human hair averages 50 microns in diameter. That 85-86 micron coating—thinner than two human hairs—protects steel for decades.

The coating isn't paint. Hot-dip galvanizing creates a metallurgical bond. Steel submerged in 445-465°C molten zinc forms zinc-iron alloy layers integral to the base metal. This bonded protection won't flake or peel, even when scratched.

86 Micron vs 100 Micron: Direct Comparison

Here's what the data shows for transmission tower applications:

| Specification | 86 Micron | 100 Micron | Difference |

|---|---|---|---|

| Coating Mass | 606 g/m² | 705 g/m² | +16.3% |

| Weight Added (per 100m²) | 4.3 kg | 5.0 kg | +0.7 kg |

| Immersion Time (typical) | 2-3 minutes | 3-4 minutes | +1 minute |

| Service Life (rural/urban) | 60-100 years | 70-115 years | +15-20 years |

| Service Life (industrial) | 35-50 years | 40-60 years | +10 years |

| Service Life (marine <5km) | 15-25 years | 18-30 years | +5 years |

| Cost Premium | Baseline | +12-18% | Variable |

| Standards Compliance | ISO 1461, ASTM A123 | Exceeds standards | Both compliant |

What Drives Coating Thickness

Three factors determine final coating thickness:

Steel chemistry matters most. Silicon content between 0.03-0.25% affects reactivity with molten zinc. Steels outside this range either form thin coatings or excessively thick ones. We specify Q355B steel for transmission line services because it consistently achieves target thickness.

Immersion time. Longer bath time builds thicker coatings. However, diminishing returns kick in after 5-6 minutes. You can't simply double the time to double the thickness.

Surface preparation. Grit blasting before galvanizing creates surface profile that increases coating thickness 15-25%. We use this technique when clients specify 100 micron or higher.

Service Life Analysis: How Long Will Each Coating Last?

Zinc corrodes predictably. Unlike paint that fails suddenly, galvanized coatings thin gradually at measurable rates.

Atmospheric Environments (C2-C3)

Rural and urban locations with low pollution. Corrosion rate: less than 1 micron per year.

- 86 micron: 60-100 years to first maintenance

- 100 micron: 70-115 years to first maintenance

Your transmission tower in a typical suburban area will outlast its design life with either coating thickness. The electrical equipment will need replacement long before the steel structure corrodes.

Industrial Environments (C4)

Moderate to high industrial pollution. Corrosion rate: 1.5-2.5 microns per year.

- 86 micron: 35-50 years to first maintenance

- 100 micron: 40-60 years to first maintenance

The extra 14 microns buys you 5-10 additional years. Whether that matters depends on your maintenance cycle and access costs.

Coastal Environments (C5-M)

Within 5km of saltwater. Highest corrosion rates: 2-4 microns per year.

- 86 micron: 15-25 years to first maintenance

- 100 micron: 18-30 years to first maintenance

For marine installations, we recommend 100 micron minimum. Some coastal projects in Africa and Southeast Asia specify 120-150 micron for 50-year service life.

| Environment Type | ISO 9223 Category | Corrosion Rate (µm/year) | 86 Micron Life | 100 Micron Life |

|---|---|---|---|---|

| Rural/Low Urban | C2 | <0.7 | 100+ years | 100+ years |

| Urban/Suburban | C3 | 0.7-2.1 | 60-100 years | 70-115 years |

| Industrial | C4 | 2.1-4.2 | 35-50 years | 40-60 years |

| Marine/Heavy Industrial | C5-M | 4.2-8.4 | 15-25 years | 18-30 years |

Factors That Affect Service Life

Elevation and airflow. Towers in valleys with poor air circulation corrode faster than hilltop installations with constant wind. Better ventilation means longer life.

Moisture and humidity. Galvanized steel performs best in dry climates. Tropical humidity accelerates corrosion but the coating still delivers decades of protection.

Sulfur dioxide levels. Improved air quality since 1990s has extended galvanized coating life by 30-40% in developed countries. Lower industrial pollution means your tower lasts longer than vintage data suggests.

Cost-Benefit Analysis: Is 100 Micron Worth It?

Let's talk numbers. For a typical 35-meter transmission tower with 180m² surface area:

Material Cost Differential

- 86 micron zinc cost: $2,850-3,100 per tower

- 100 micron zinc cost: $3,300-3,650 per tower

- Premium: $450-550 per tower (15-18% increase)

These figures assume $3.20/kg zinc price. Market fluctuations affect actual costs.

Lifecycle Cost Comparison (35-meter tower example)

| Cost Factor | 86 Micron | 100 Micron | Notes |

|---|---|---|---|

| Initial galvanizing | $3,000 | $3,500 | Baseline |

| Expected service life (urban) | 75 years | 90 years | +15 years |

| Maintenance cycles | 2-3 touch-ups | 1-2 touch-ups | Fewer interventions |

| Total lifecycle cost | $3,800 | $4,100 | Including maintenance |

| Cost per year of service | $50.67 | $45.56 | 100 micron wins |

Break-even analysis: The $500 upfront premium pays for itself through extended service life and reduced maintenance. You break even around year 12-15, then enjoy 15+ additional maintenance-free years.

When 100 Micron Makes Financial Sense

Choose the thicker coating when:

- Tower locations are difficult to access (mountains, wetlands)

- Labor costs for future maintenance exceed material cost savings

- Project requires 50+ year design life

- Coastal or industrial exposure demands extra protection

- Client specifications require extended warranty periods

Our manufacturing experience across 20+ export markets shows that buyers in harsh coastal environments consistently specify 100 micron or higher. The upfront cost difference is negligible compared to tower replacement or extensive repairs.

Application Recommendations: Which Thickness for Your Project?

Use 86 Micron For:

Inland rural and urban installations. Standard atmospheric conditions with corrosion rates under 2 microns per year. The minimum standard thickness provides 60-100 year service life.

Budget-sensitive projects. When initial cost matters more than lifecycle optimization. Government tenders often specify minimum standards to qualify maximum bidders.

Easy-access locations. Sites where future maintenance crews can reach towers without helicopters or specialized equipment.

Our Q355B galvanized steel angles and members meet ISO 1461 at 86 micron thickness for tower steel fittings used in standard transmission projects.

Use 100 Micron For:

Coastal installations. Anything within 10km of saltwater, especially direct spray zones. The extra zinc provides critical buffer against accelerated marine corrosion.

Industrial zones. Chemical plants, refineries, heavy manufacturing areas with elevated pollution. Corrosive atmospheres eat through standard coatings faster.

Critical infrastructure. Primary transmission corridors where outages cost millions per hour. The extended service life reduces failure risk.

Difficult terrain. Mountain towers, river crossings, protected wildlife areas where future access is expensive or restricted.

Long-term contracts. Build-own-operate-transfer (BOOT) projects with 25-30 year concession periods benefit from coatings that outlast the contract term.

| Location Type | Distance from Coast | Pollution Level | Recommended Coating | Annual Corrosion Rate |

|---|---|---|---|---|

| Rural inland | >50km | Low | 86 micron | 0.5-1.0 µm/year |

| Urban/suburban | >20km | Moderate | 86 micron | 1.0-2.0 µm/year |

| Industrial zone | Any | High | 100 micron | 2.0-4.0 µm/year |

| Coastal inland | 5-10km | Low-Moderate | 100 micron | 2.5-3.5 µm/year |

| Direct coastal | <5km | Moderate-High | 100-120 micron | 4.0-6.0 µm/year |

Special Considerations

Mixed environments. Some projects span different exposure zones. A transmission line from mountain to coast might use 86 micron for highland sections and 100 micron approaching the shore.

Future development. Rural areas today might become industrial zones in 20 years. If regional development plans indicate future pollution sources, spec the thicker coating now.

Regulatory requirements. Some markets mandate specific coating thickness regardless of environment. Always verify local codes before finalizing specifications.

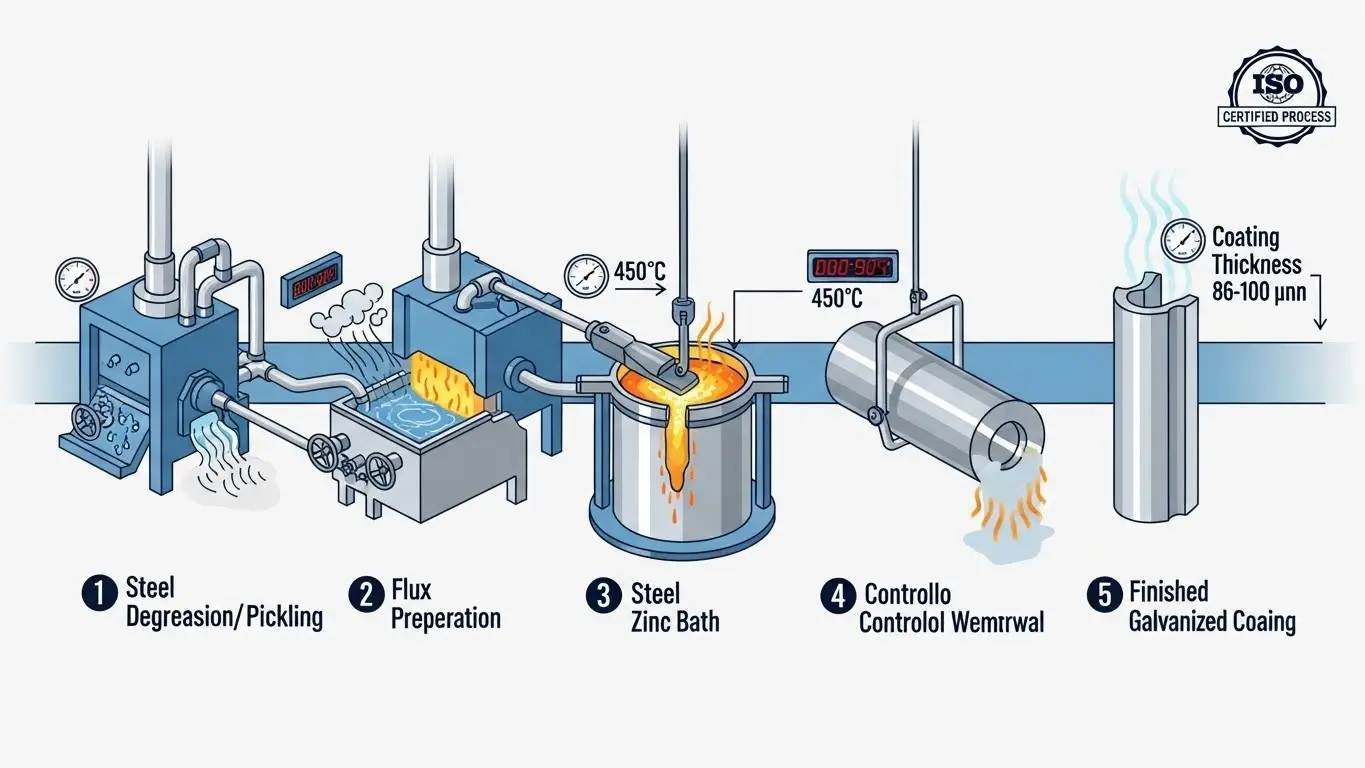

Manufacturing Process: How We Achieve Consistent Thickness

Our galvanizing facility in Deyang operates under ISO 9001 certification with strict process controls:

Pre-Treatment Sequence

- Degreasing removes oils and manufacturing residues

- Pickling in hydrochloric acid strips mill scale and rust

- Fluxing prepares the surface for optimal zinc adhesion

- Drying at 65-70°C eliminates moisture

Hot-Dip Galvanizing

Steel components submerge in molten zinc bath at 445-465°C. Temperature control within ±5°C is critical. Too hot creates brittle coatings. Too cool reduces thickness.

For 86 micron: Immersion time averages 2.5-3 minutes depending on steel thickness and chemistry.

For 100 micron: We extend immersion to 3.5-4 minutes or use grit-blasted surface preparation.

Withdrawal speed matters. Slow withdrawal allows excess zinc to drain, preventing thick deposits at bottom edges. Fast withdrawal traps molten zinc, creating uneven coating.

Quality Control Methods

Every production batch undergoes coating thickness measurement using magnetic induction gauges per ASTM E376. We test minimum 5 locations per component:

- Base of vertical members

- Mid-height sections

- Connection points and joints

- Highest elevations

- Areas with complex geometry

Average thickness must meet specification minimums. Individual readings can vary ±10%, which is industry standard tolerance.

We also perform visual inspection for:

- Surface smoothness (no sharp zinc spikes)

- Coverage completeness (no bare spots)

- Acceptable ash/dross inclusions

Our substation structures and lattice towers meet international quality standards through this rigorous process.

Weight Impact on Tower Design

Engineers often ask: "Will thicker galvanizing affect structural calculations?"

Short answer: No significant impact.

| Tower Type | Surface Area | 86 Micron Weight | 100 Micron Weight | Difference |

|---|---|---|---|---|

| 20m Distribution Tower | 95 m² | 4.1 kg | 4.7 kg | +0.6 kg |

| 35m Transmission Tower | 180 m² | 7.7 kg | 9.0 kg | +1.3 kg |

| 55m High-Voltage Tower | 320 m² | 13.7 kg | 15.9 kg | +2.2 kg |

| 75m Extra-High Voltage | 510 m² | 21.9 kg | 25.4 kg | +3.5 kg |

A 35-meter tower weighs approximately 3,500-4,200 kg bare steel. Adding 1.3 kg of extra zinc represents 0.03% weight increase—structurally negligible.

Wind loading, ice accumulation, and conductor tension create forces hundreds of times larger than galvanizing weight variance. Foundation design doesn't change between 86 and 100 micron specifications.

Common Challenges and Solutions

Challenge: Coating Exceeds 120 Micron

Problem: Excessively thick coatings can become brittle and crack under mechanical stress or thermal cycling.

Cause: High silicon steel (>0.25% Si content) reacts vigorously with molten zinc, creating uncontrolled growth.

Solution: Specify low-silicon steel grades. If steel chemistry can't change, accept thicker coating as trade-off for better corrosion protection. Brittle thick coatings still protect steel effectively—they just require gentler handling during transport and installation.

Challenge: Coating Below Minimum Specification

Problem: Some areas measure 70-75 micron when 86 micron was specified.

Cause: Aluminum-killed steels with very low silicon sometimes form thin coatings. Surface contamination during processing also inhibits zinc adhesion.

Solution: Grit blast before galvanizing to create mechanical bonding surface. Shot blasting to Sa2½ standard typically adds 15-20 microns to final thickness. If coating still falls short, apply zinc-rich repair paint per ASTM A780 to bring areas up to specification.

Challenge: Uneven Coating Distribution

Problem: Bottom edges show 150 micron while top areas measure 80 micron.

Cause: Molten zinc drips and pools at lower edges during withdrawal from bath.

Solution: Optimize withdrawal angle and speed. Centrifuging small components immediately after galvanizing removes excess zinc. For large assemblies, design drainage holes at low points to prevent zinc accumulation.

At our facility, we've solved these issues through 17 years of processing experience. Our engineering team works with clients during tower design services to optimize member geometry for consistent galvanizing results.

Frequently Asked Questions

ISO 1461 requires minimum 85 micron average coating for steel sections greater than 6mm thick. ASTM A123 specifies 86 micron for structural shapes. Both standards represent baseline corrosion protection suitable for normal atmospheric exposure. Regional codes may specify higher minimums for coastal or industrial environments.

100 micron coating typically costs 12-18% more than 86 micron specification. For a standard 35-meter transmission tower, the premium runs $450-550 per tower at current zinc prices. However, the thicker coating extends service life by 15-20 years and reduces maintenance frequency, delivering better long-term value in harsh environments.

100 micron minimum for coastal installations within 5km of saltwater. Marine environments with salt spray and high humidity accelerate zinc corrosion to 2-4 microns per year. The extra thickness provides necessary buffer for 20-30 year service life. Direct spray zones may require 120-150 micron for adequate protection.

No. 100 micron coating adds approximately 0.7 kg per 100 m² surface area compared to 86 micron. For typical transmission towers, total weight increase ranges from 0.03-0.08% of bare steel weight. This negligible difference doesn't affect structural calculations, foundation design, or transportation logistics.

Magnetic thickness gauges per ASTM E376 provide non-destructive measurement. Inspectors test minimum 5 locations per component and calculate average thickness. Individual readings typically vary ±10% from average, which is acceptable industry tolerance. Some projects also use gravimetric methods (coating mass per surface area) as secondary verification.

Hey, I’m Chunjian Shu

"X.Y. Tower: Reliable, innovative solutions for high-quality towers and electrical equipment with professional service.